While industrial designer and mechanical engineer Ryan Tilley always had an interest in mobility, it wasn’t until he participated in an RMIT study tour to Singapore in 2017 that he began exploring it in depth. The program involved spending three days getting around the city in a wheelchair, mimicking loss of movement.

The importance of understanding the challenges faced

“You don’t see the nuances until you’re in the chair. It’s amazing to witness the empathy component, the looks you get and the fact that people are literally looking down on you helped me understand,” Ryan observed.

“Knowing that I could use my skills to make a difference was the start of my journey in assistive design and technology.”

After forming a friendship with engineer and wheelchair user Huy Nguyen, together they developed Gecko Traxx – and transformed the all-terrain mobility accessory into a fully commercialised business with sales across Australia and overseas. He soon met Bryce Alman, who in addition to being a wheelchair rugby paralympian, was also an early tester and supporter of Gecko Traxx. When Ryan pitched the idea of a lightweight, 3D-printed wheelchair to Bryce, Rove Wheelchairs was born.

Reinterpreting the wheelchair

Aside from the engineering advantages, the emphasis was on making a chair that looked sexy. Ryan had long questioned why medical products had to look and feel so sterile, rather than being something to be desired.

Ryan, Bryce and Keith Klein – the father of a wheelchair athlete – spent close to 18 months developing their protype. The brief was to create the lightest weight manual wheelchair that they could, for it to look amazing, be customisable and made in Victoria. That in itself was no small feat considering that 95% of assisted technology products are manufactured overseas and imported.

According to Ryan, “with the shutdown of automotive manufacturing in Victoria, there’s a large pool of talented designers and practitioners with capacity and expertise that is largely untapped. There are so many opportunities for the state to become a centre of excellence for the mobility sector.”

The Rove team spent months conducting market research, sending out questionnaires to wheelchair users, medical practitioners, occupational therapists, engineers, physiotherapists and carers. The hundreds of responses they received provided a framework for design, functionality, materials and features.. Above all, feeling confident while in the chair was identified as key.

User-centric design as a catalyst

The overarching design philosophy at Rove Wheelchairs has always centred on the user. Having Bryce’s insight and lived experience on hand made the design process more authentic, with quicker iterations and ultimately a better product.

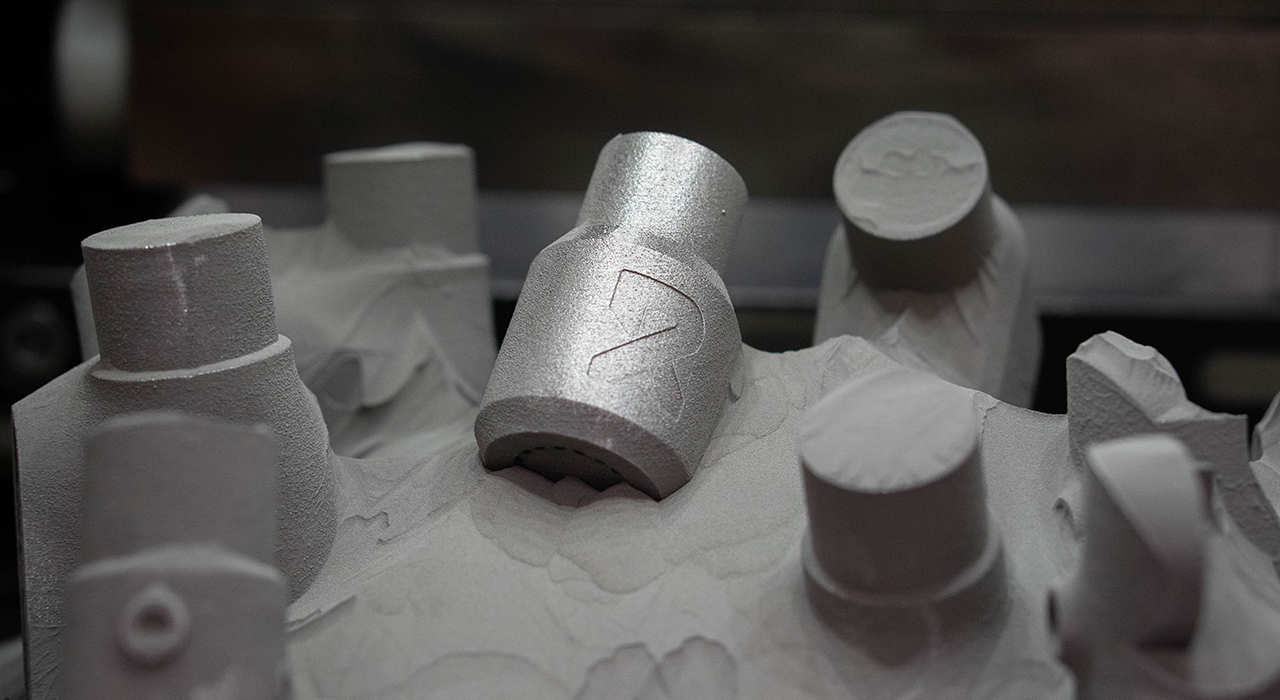

“Taking technology and design principles from the bike industry and applying it to wheelchairs, adding automotive styling lines, using carbon fibre rather than aluminium tubing and manufacturing using 3D printing creates a work of art rather than a standard piece of equipment.”

The result is the world’s first custom-made, titanium and carbon fibre 3D-printed wheelchair. Lighter than other chairs, Rove Wheelchair users feel more independent and gain a greater sense of confidence from being in a good-looking chair that they can customise to suit their personality as well as their needs.

Despite being a premium product, Ryan credits the Australian National Disability Insurance Scheme (NDIS) for enabling better accessibility. The NDIS, and depending on the circumstances, the Traffic Accident Commission (TAC) both cover up to 100% of the cost of a Rove Wheelchair – making it within most wheelchair users’ reach. Rather than settling for a standard utilitarian chair, users can now enjoy a beautifully designed, customised ride that is an extension of their personality and was made locally.

Award nominations aren’t new to Ryan, having already won the Victorian Premier’s Design Awards) Best in Category – Student Design in 2019 for Gecko Traxx. That innovation also earned him an Australian Good Design Award, Australian James Dyson Award and James Dyson International Awards runner up.

Awards as a gateway to spreading awareness

“Mobility, especially in wheelchair design, is an underrepresented space. Winning awards like the VPDA is an amazing vehicle for elevating the importance of the design process, highlighting features that people don’t often see. They raise the profile of mobility design as a craft and provide a platform for those working in the accessibility space,” Ryan commented.

“Ultimately, the best part is hearing the stories from our customers, like someone saying that they’ve been able to go down to the beach with their children for the first time, rather than watching them from the car park. The outcome of thoughtful design can make such an impact – that’s why I do it,” he added.

The future looks bright for Rove Wheelchairs and its team of five – two of whom are wheelchair users. Their manufacturing facility in Carrum Downs was purpose-built in 2022 to accommodate all levels of ability, creating an accessible workspace for its team which will likely expand to meet growing national and international demand. Rove is committed to employing more people in wheelchairs, not only because it‘s important to provide opportunities, but because the connection they feel to the work is invaluable.

Australian of the Year and disability advocate Dylan Alcott recently began using a Rove Wheelchair.

“It’s a great fit and a perfect partnership, raising our profile and boosting awareness of the importance of accessibility for the disabled community,” said Ryan.

This year the company’s focus is on improving internal processes and streamlining its 3D manufacturing capabilities while in 2024, they are setting their sights on breaking into the US market and ramping up exports to North America.

With Rove Wheelchairs, Ryan and his team are reshaping the future of mobility right here in Victoria.