The design process began with getting a deeper understanding of the problem. Insights were gathered directly from the students who had experienced the issue firsthand. Considerations such as functionality, cost and realism were mapped out to determine a balance that would best meet the needs of the teaching environment. Similar existing solutions were researched and their pros & cons were analysed.

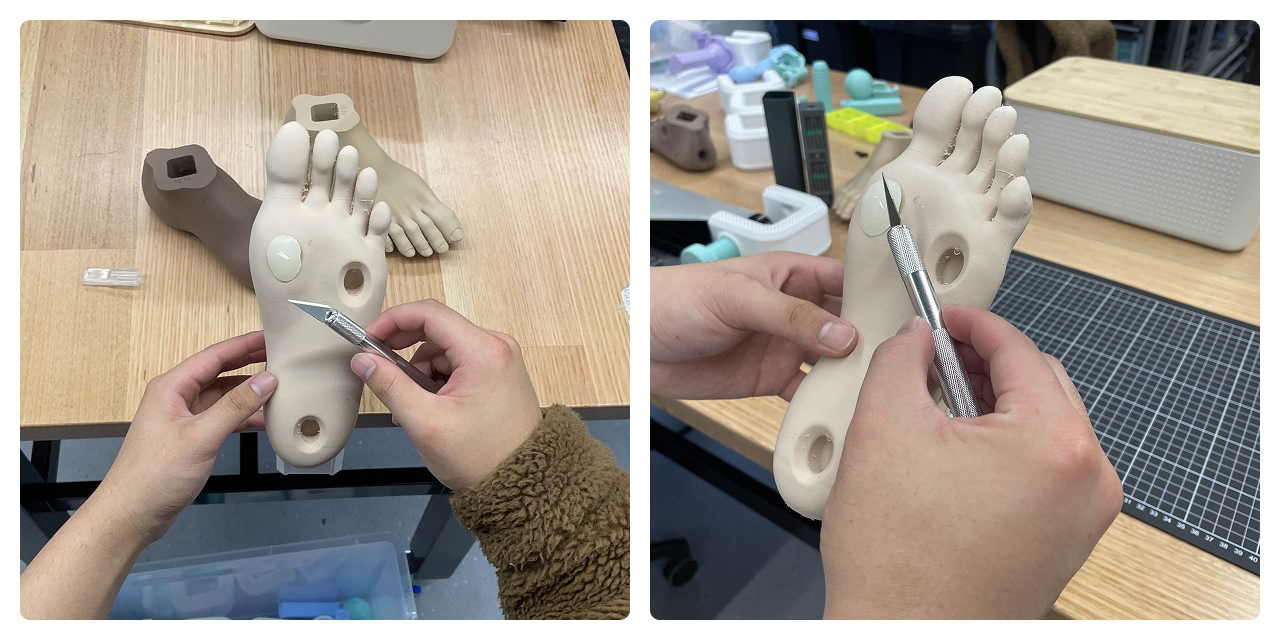

Several early prototypes were created and tested by Dr Ho’s students. Their feedback shaped each stage of the design, ensuring that user centred design principles were followed closely. Many improvements to usability and performance would likely have been missed without these testing sessions, which proved crucial in refining the product.

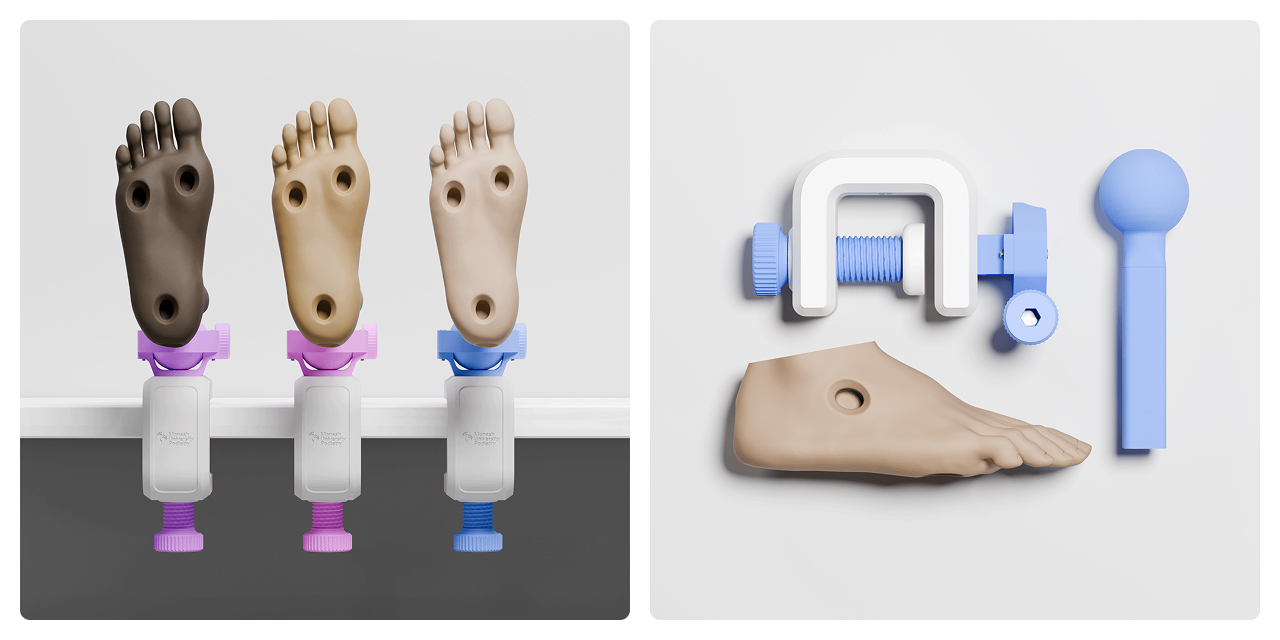

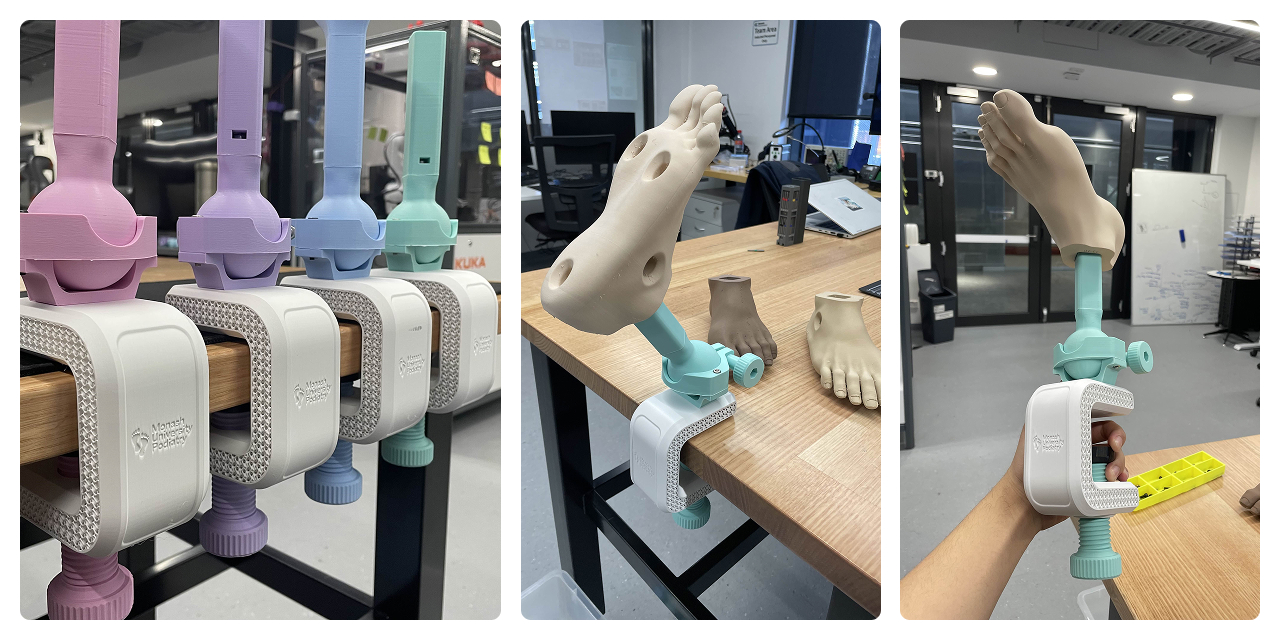

Although a higher level of anatomical accuracy was technically achievable, such as including bones or a full lower limb, it was recognised that cost and practicality were more important to both students and institutions. A balance was reached, where the kit remained realistic and functional while staying affordable and accessible. Aesthetics were also considered carefully. In contrast to the harsh, clinical appearance of existing tools, the EduKit was designed with soft pastel colours and approachable forms to help students feel more comfortable when using it. Production was a key design constraint.

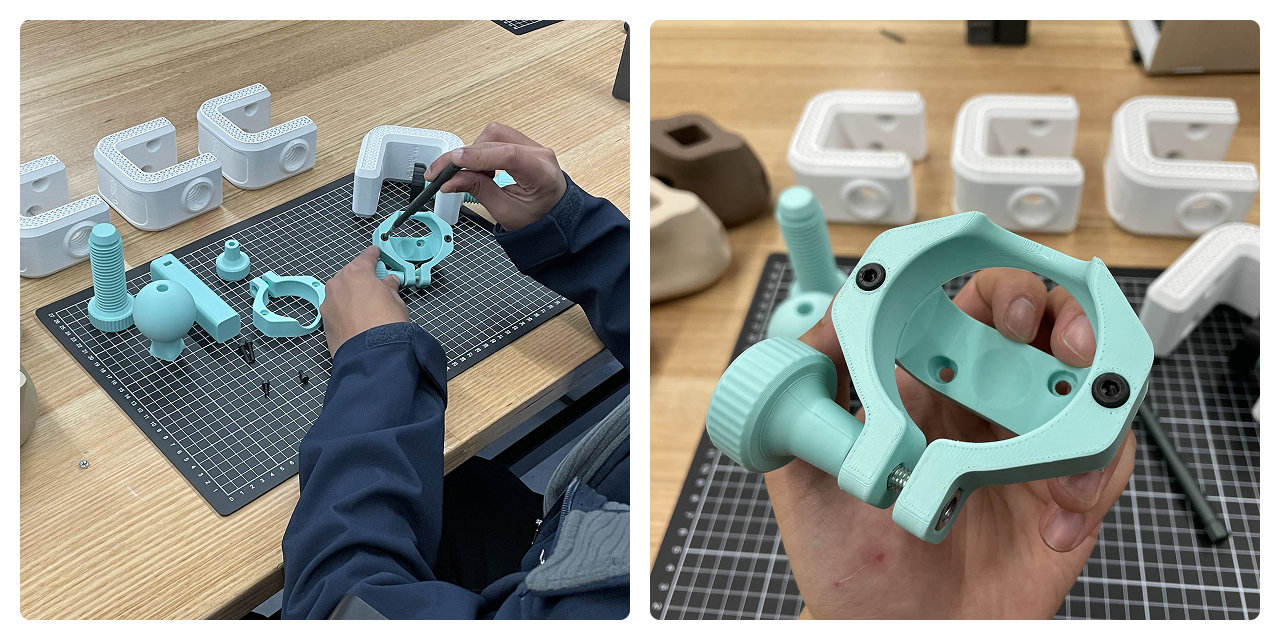

Demand for the kits is too low for injection moulding, yet too high for hand-built units. To address this, the design was tailored for large format FDM 3D-printing using Monash Automation’s Matrix print farm. This allowed scalable production without expensive tooling. Every plastic component in the kit was designed with FDM-specific considerations, including material flow, tolerances, support removal, and surface finish. Parts were also optimised for simple assembly and durability.

By adopting additive manufacturing early, a cost effective, scalable pathway was created, ensuring the EduKit could be efficiently deployed without compromising on usability or realism.