The design process started with surveying and interviewing healthcare workers to identify pain points on the job. Paramedics pointed out that the most common ailment came from muscular injuries, and together through journey mapping, we determined that lifting heavy bags in and out of the ambulance side door was a major contributing factor. After discussing and sketching ideas, early stage prototypes were built from cardboard and PVC pipe to explore size, height, and movement. These were tested and refined through feedback from paramedics in hands-on workshops.

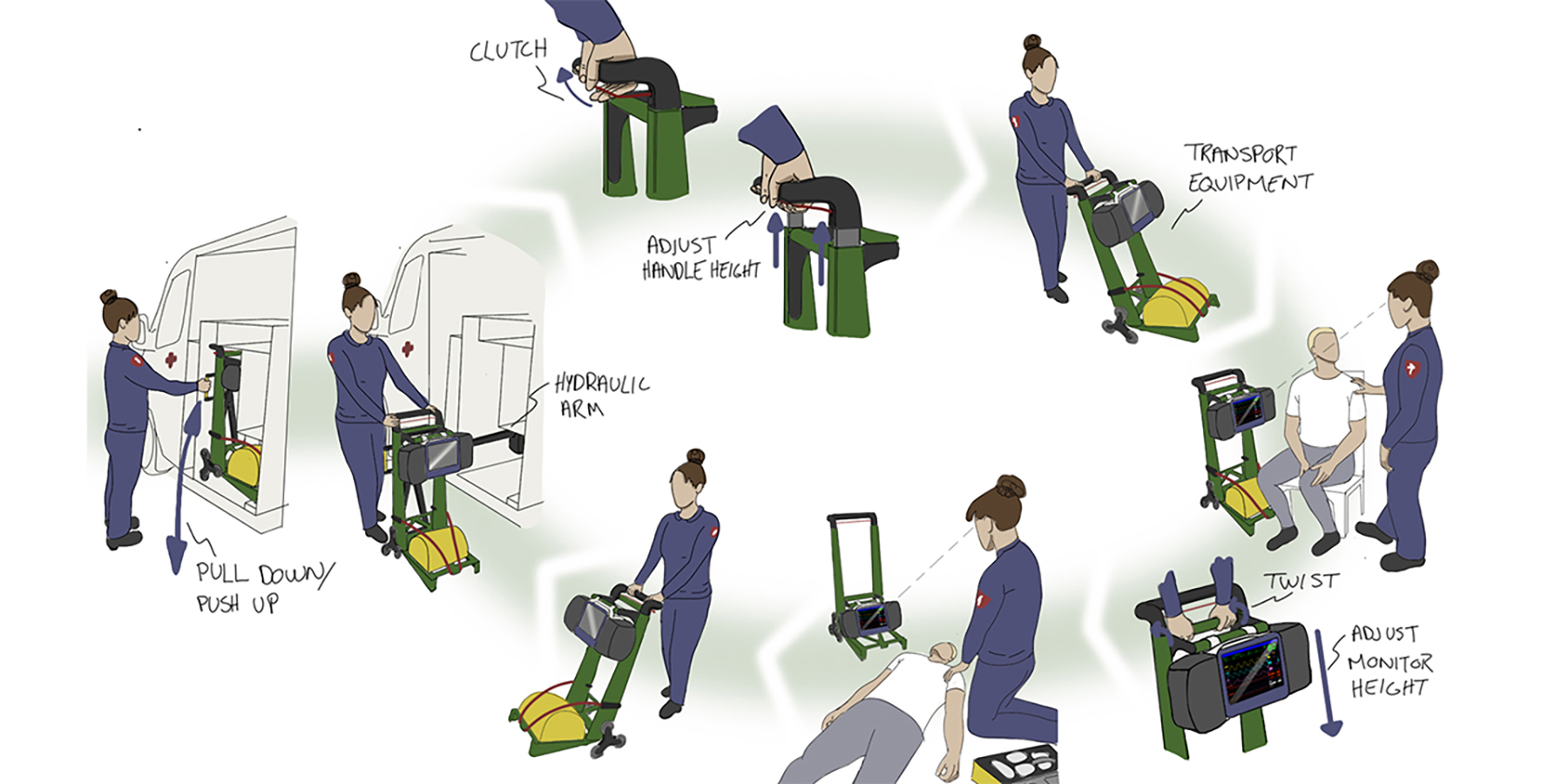

Over time, key features were added based on their feedback; like a hydraulic lever in the ambulance to help lower and raise the trolley, a monitor hook for better screen visibility, and tri-wheels that make it easier to go up and down stairs. The handlebar was also made adjustable to suit paramedics of different heights. The final prototype is made from laser-cut, bent aluminium sheets that are welded together. It’s simple, sturdy, and can be made with standard tools and processes. With minor adjustments to the bag tower in the ambulance, the trolley slots straight into the ambulance’s existing setup without interfering with the paramedics workflow.

What sets this project apart is how closely it was developed with paramedics. Their feedback shaped every step. Throughout the process, injury prevention, workflow efficiency, and ambulance compatibility were prioritised. The design not only meets the brief, it exceeds it by creating a thoughtful, scalable, and long-overdue ergonomic solution to an industry-wide issue.