Collection: The design of T.R.I.A.L. began with a real-world material inquiry: collecting discarded or damaged furniture from the streets and hard rubbish zones of inner-city Melbourne. These items—often left behind at end of tenancy—ranged from broken to fully functional.

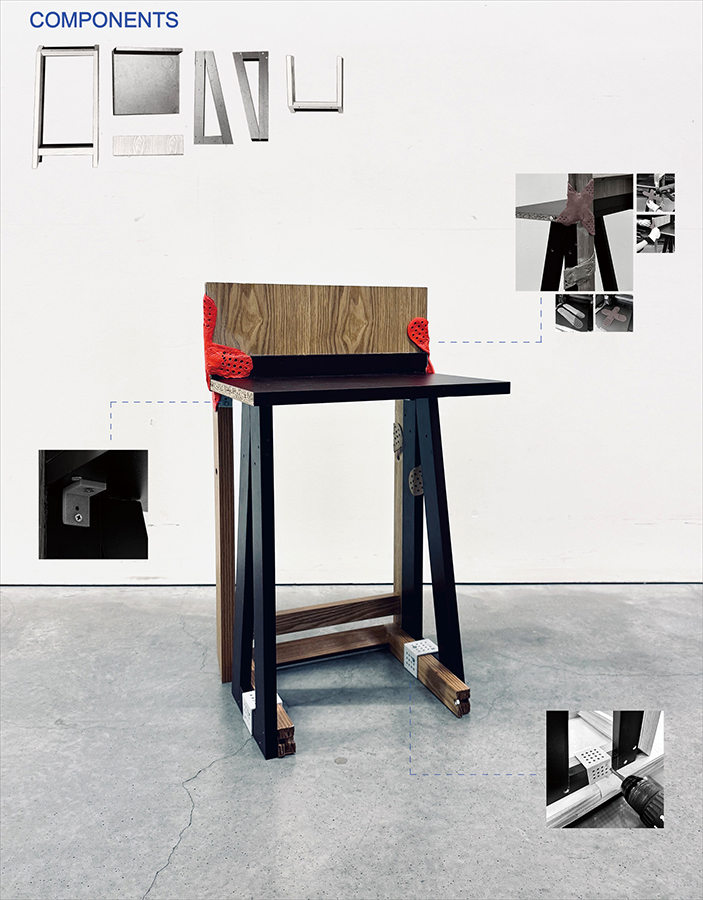

Digital Scanning / Component Library: Rather than starting with a predefined form, the design process responded directly to what was found. Each object was dismantled into its components—legs, backrests, panels, and shelves—and carefully documented. Selected parts were 3D scanned and digitally archived, forming a flexible library of irregular forms.

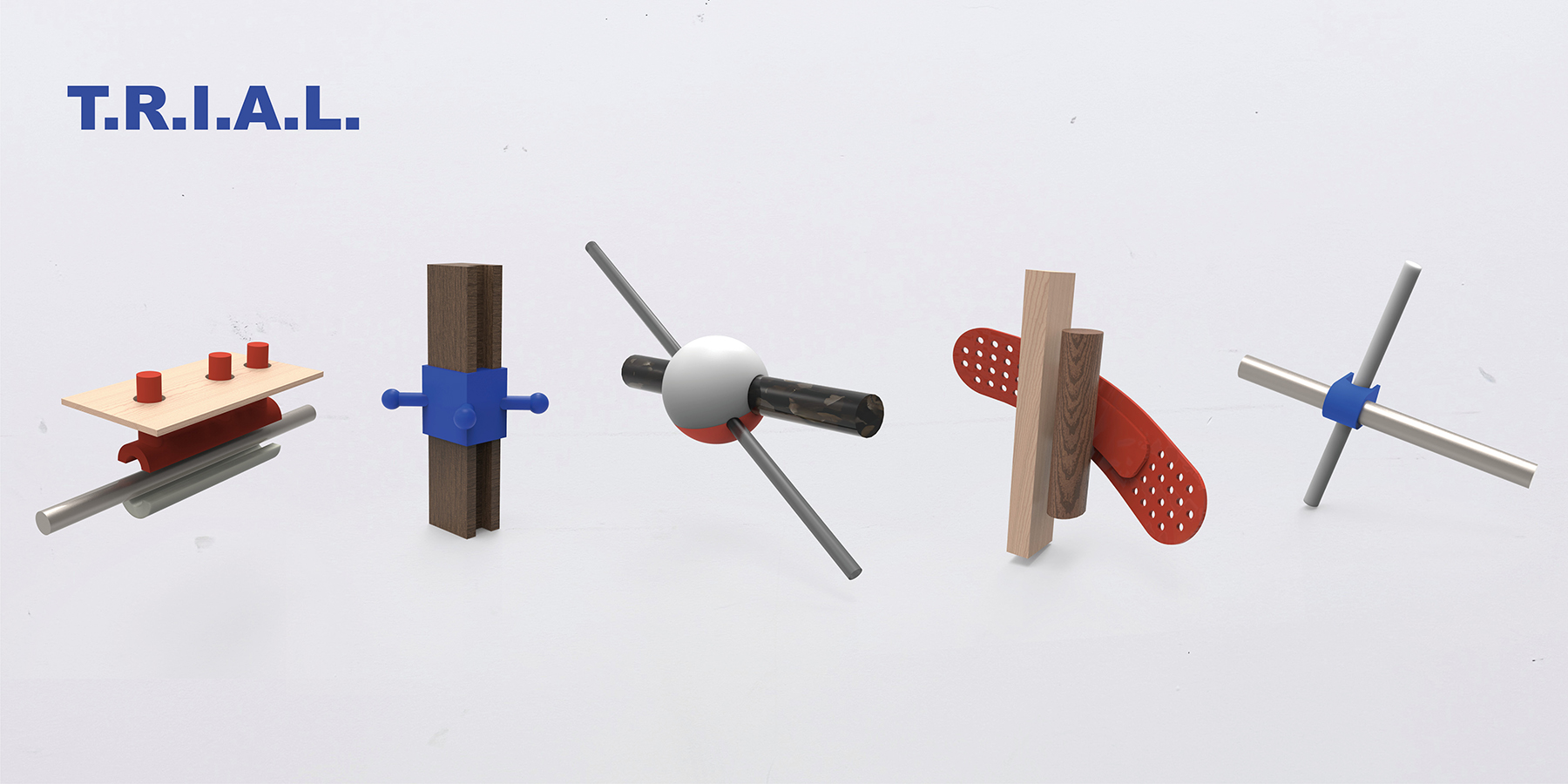

Digital Modelling + Component Recombination: This archive, managed within Rhino’s modelling environment, served as a resource hub for rapid ideation, enabling component recombination based on availability rather than ideality.

Connector Design and Fabrication: From the digital library, combinations were explored, and connectors were designed using Rhino and Grasshopper. These were tailored to the geometries of salvaged parts and fabricated with 3D-printed Polylactic Acid (PLA), a recyclable, biodegradable material made from plant enzymes. The connectors were intentionally left visible, serving as both structural solutions and expressive markers of transformation and repair.

Assembly Process: Guided by the material conditions and user needs, a series of experimental furniture pieces were developed—including a chair, side table, floor lamp, clothes rack, and spatial divider. Each piece emerged through hands-on iteration rather than standardisation, reflecting a design approach rooted in testing, discovery, and respectful reuse.

This six-stage workflow—collection, scanning, modelling, recombination, connector fabrication, and assembly—forms a responsive, low-waste design method. It offers a scalable model for localised reuse initiatives, not only producing furniture but rethinking the ethics and poetics of making. Through this process, T.R.I.A.L. reframes furniture not as a static product, but as a dynamic medium for exploring material value, repair, and everyday living.