The ZERO PLASTIC lunchware range was developed through a careful design process with a clear objective: to eliminate all plastic from the product while maintaining everyday usability. It evolved from an earlier Victorian Premier’s Design Award-winning range, but this time with a stricter materials approach and a deeper focus on health and environmental outcomes.

The process began with feedback from existing customers, combined with ongoing research into the effects of microplastics and the limitations of plastic-based foodware. These insights shaped a brief that prioritised performance, durability, and food safety, delivered through materials not traditionally used in this category.

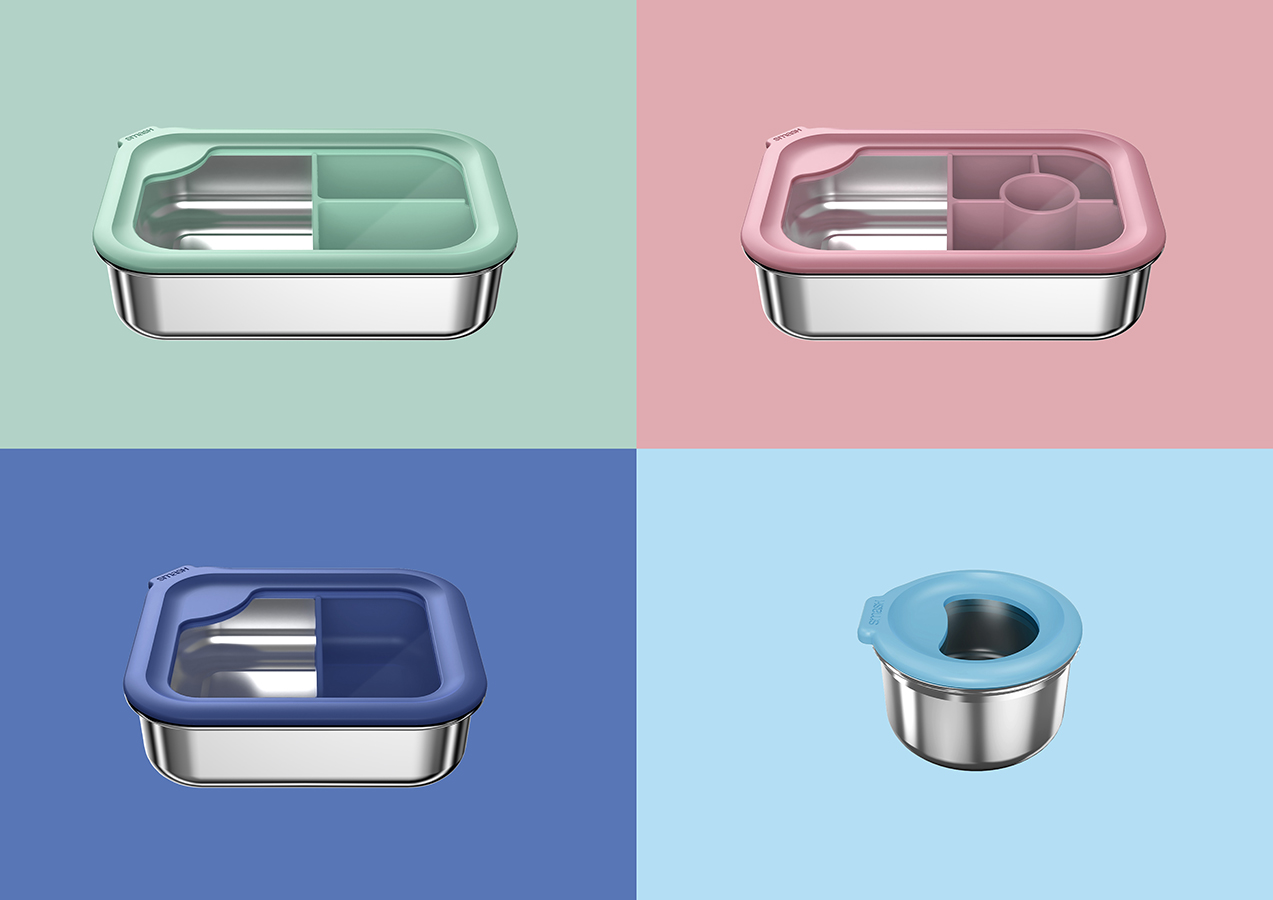

Material selection was a core part of the process. After researching options, the solution centred around food-grade stainless steel, tempered glass, and silicone. Each material had to meet practical requirements like microwave and dishwasher safety, ease of cleaning, and resistance to odour and staining.

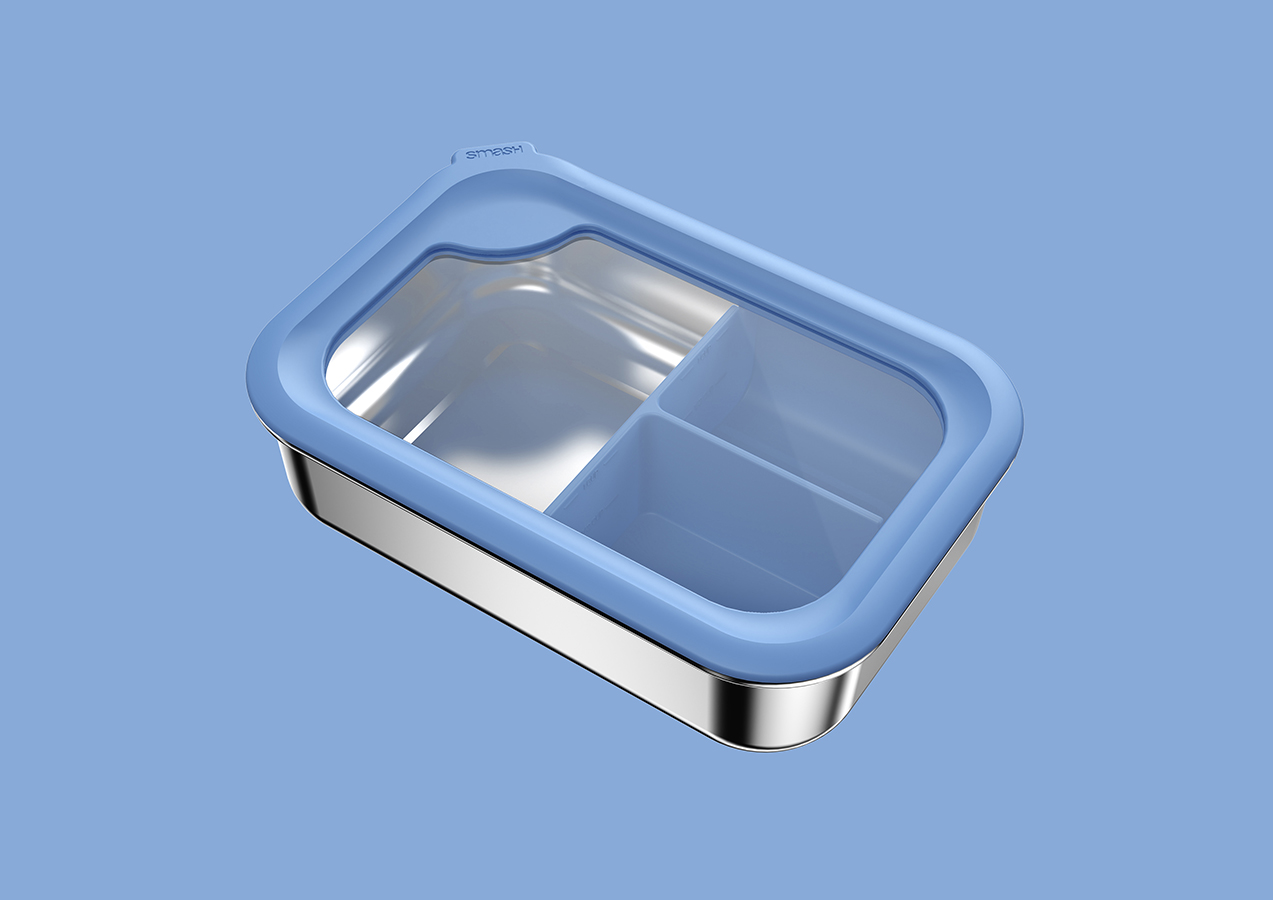

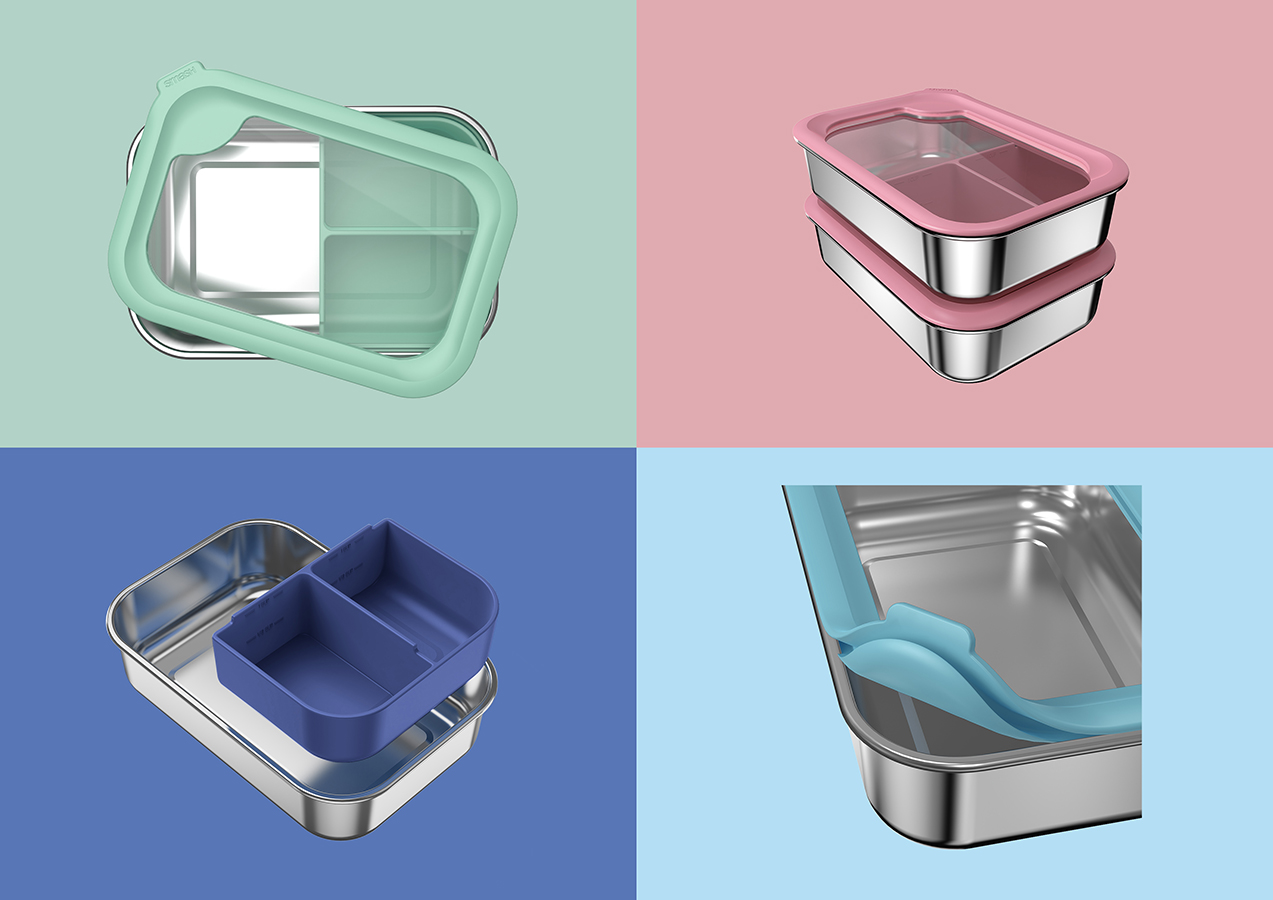

One of the main challenges was replacing the plastic lid. Tempered glass, while safer than untreated glass, needed protection and sealing. The solution was to encase the glass in a custom silicone surround, which solved multiple issues at once: creating a leak-proof seal, allowing air to escape on closure, removing the need for clips. While also protecting the edges from breakage.

Built-in dividers were replaced with removable silicone compartments, offering more flexibility for packing and reheating. The design was refined over several rounds of prototyping and use testing, with adjustments made to fit, feel, and ease of cleaning.

Final components were tooled and sourced through established suppliers, and the product was brought to market with plastic-free packaging.

The result is a professionally resolved product that meets the original design brief and introduces meaningful improvements. It demonstrates that plastic-free foodware can meet real-life needs without compromise.