Our process began with extensive research into materials, form factors, and user needs. Over 50 enclosure prototypes were designed and tested for frequency response, cone control, and acoustic dispersion. Standard sealed and vented configurations failed to meet our criteria for clarity and efficiency — especially at low frequencies.

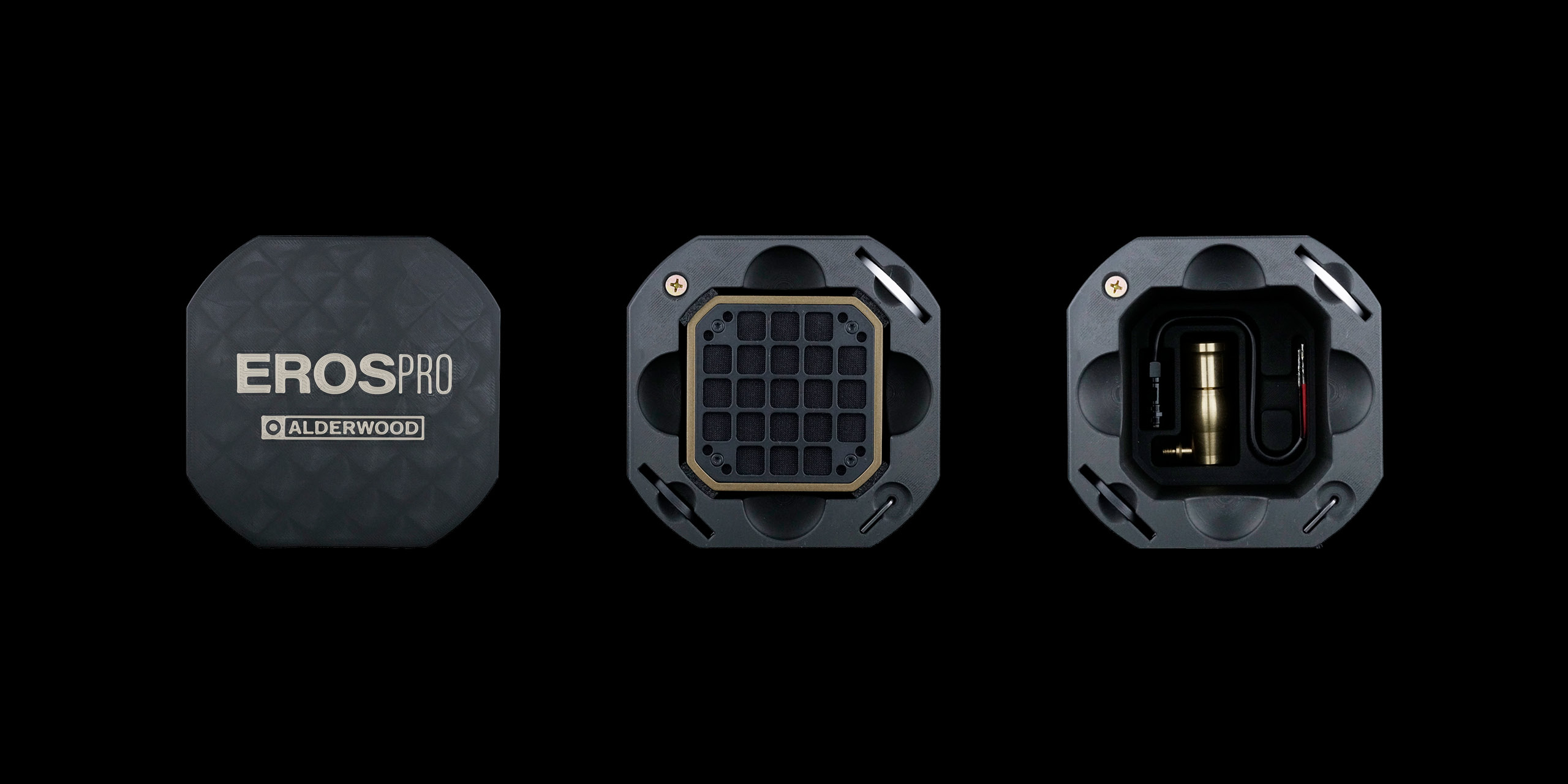

This led to three key innovations. First, we developed a proprietary acoustic lens that enhanced off-axis response, delivering an ultra-wide 170° sound field. Combined with our internal multi-path porting system, the result was immersive, distortion-free sound in a compact footprint.

Second, we invented a proprietary air valve system — a mechanical innovation that regulates internal air pressure to prevent over-excursion and improve bass clarity. Acting like a dynamic suspension, the valve gives the speaker deeper low-end response without relying on digital signal processing — a world-first in speaker design.

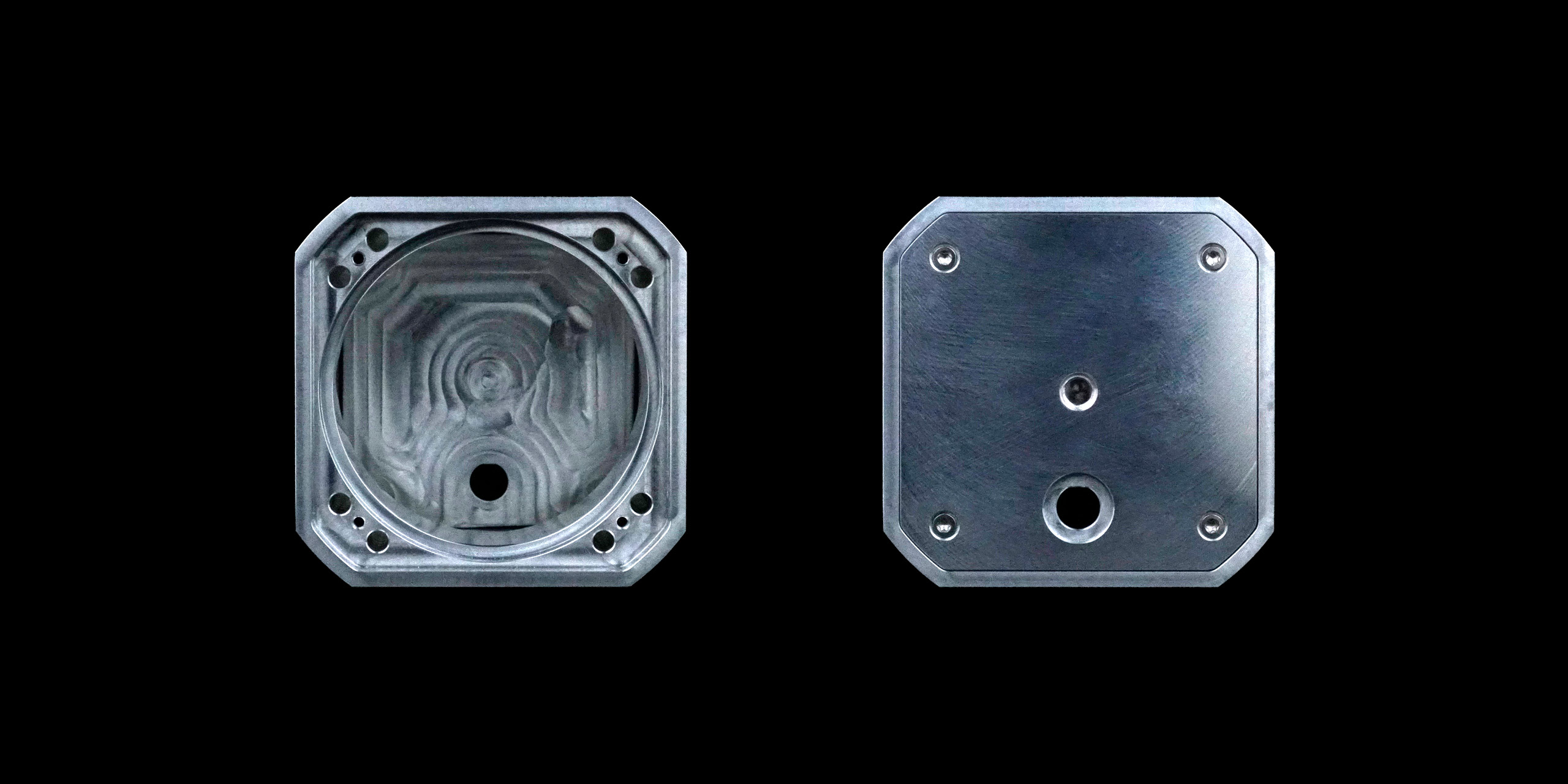

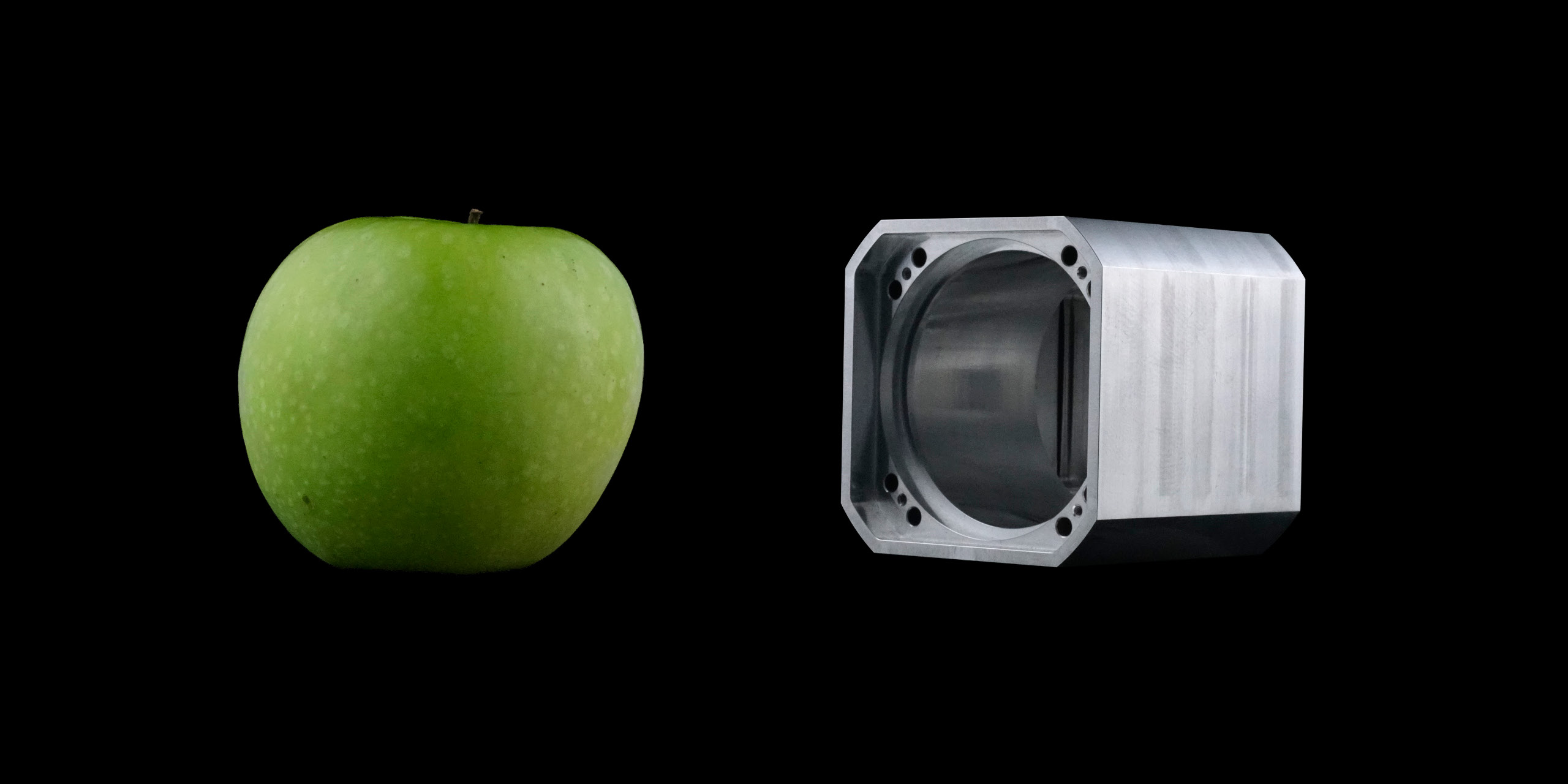

Third, we transitioned to a billet-machined aluminum chassis for its rigidity, thermal performance, and infinite recyclability. This structure was coated in ceramic paint, chosen for its non-toxic durability and ability to support custom finishes — ensuring each speaker could blend into or stand out in diverse architectural settings.

Parallel R&D was conducted on packaging. We developed custom, biodegradable 3D-printed inserts made from sugarcane waste — eliminating plastics while providing precision protection and a premium unboxing experience.

Every design element — from mechanical structure to packaging and reparability — was refined through iterative testing and user feedback. The result is a speaker that exceeds traditional performance metrics while delivering aesthetic versatility and long-term environmental responsibility.