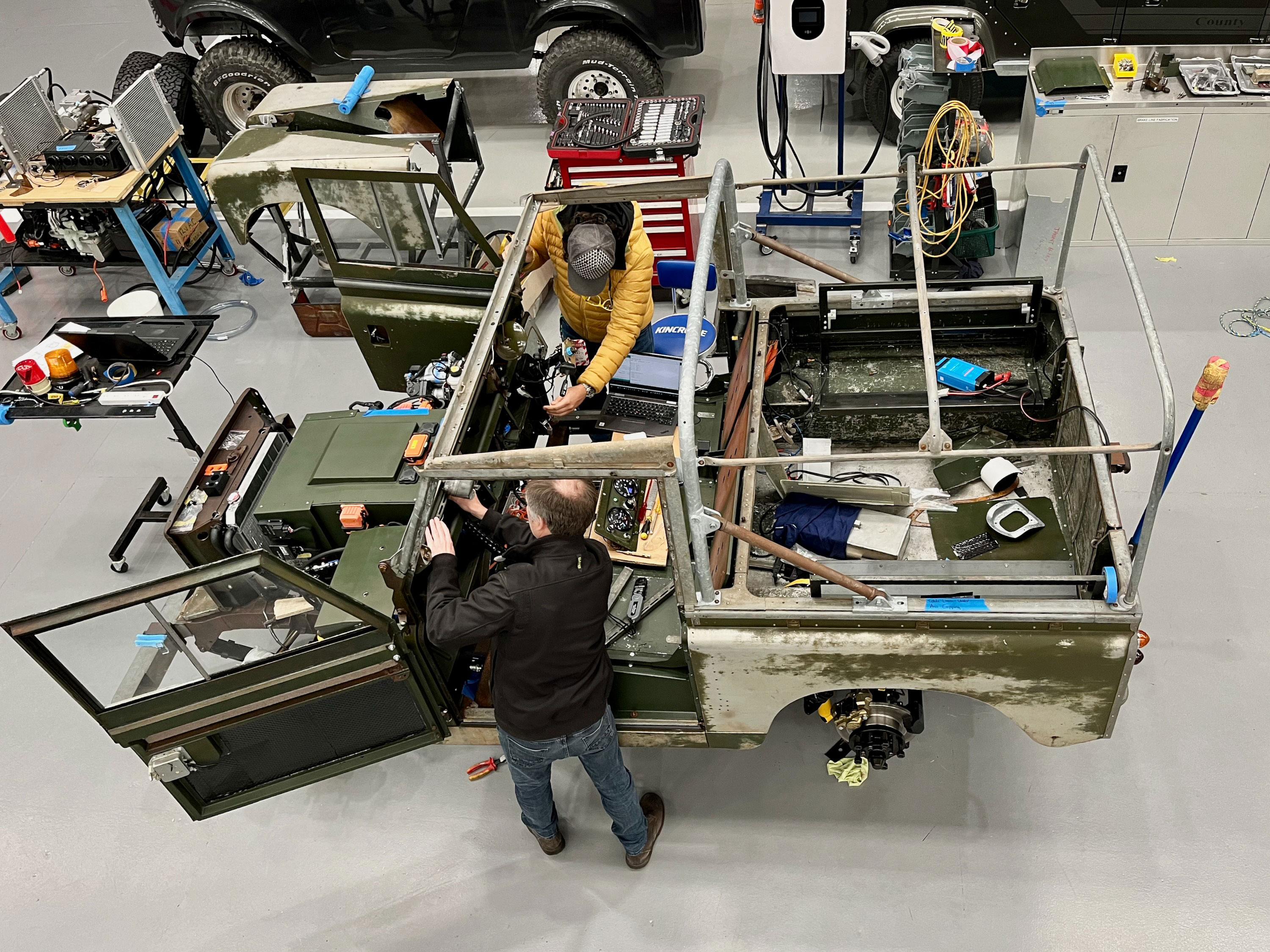

Jaunt’s Victorian-based engineering team used a mix of digital and physical development to create Generation 2. CAD modelling, FEA and 3D printing enabled validation of custom parts including battery enclosures, drive unit mounts, seatbelt hoops and accessory brackets.

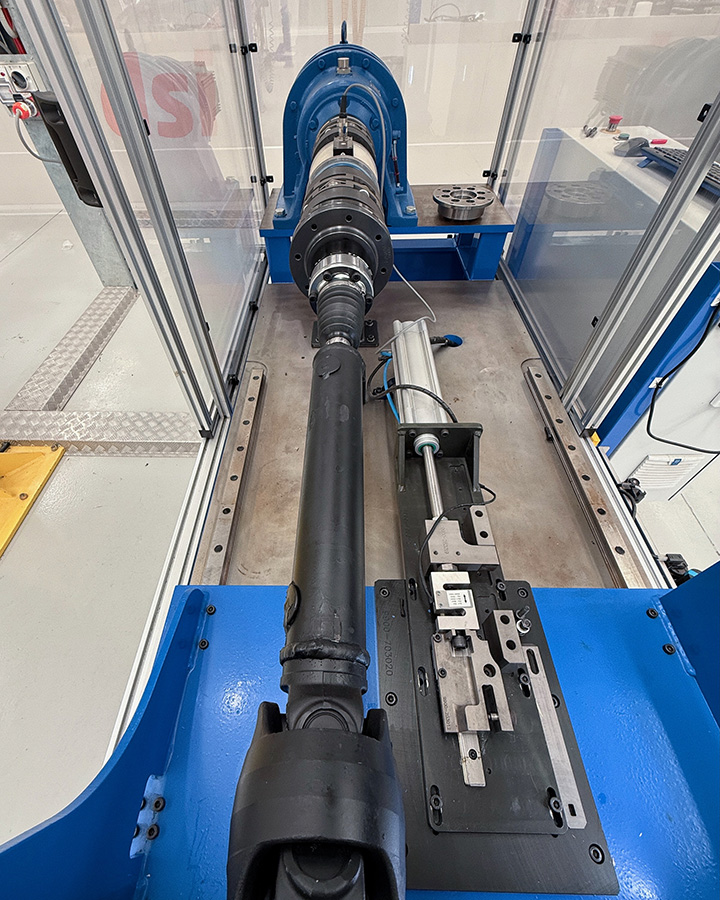

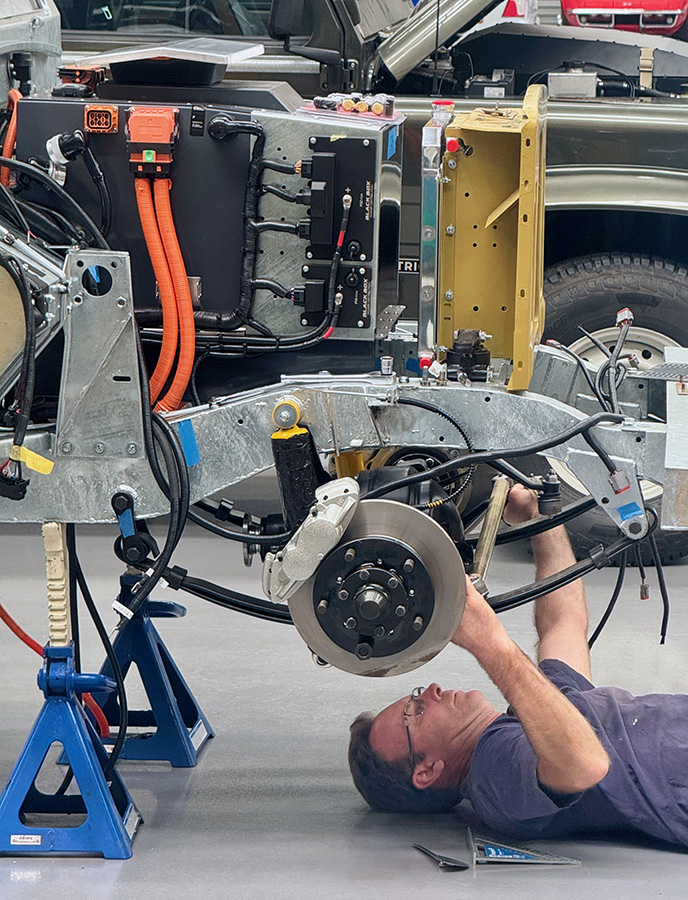

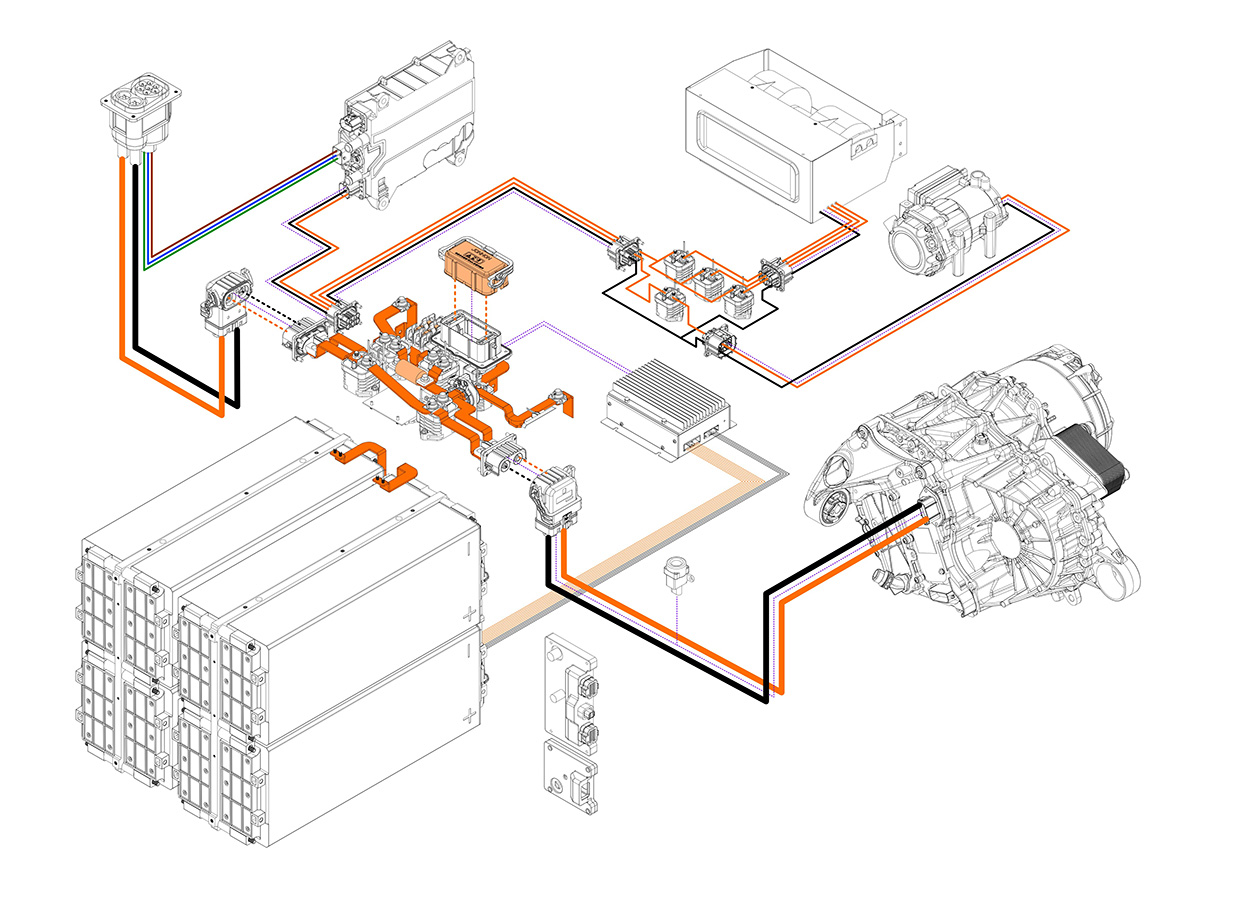

Every system - brakes, driveline, climate control and low-voltage architecture - was designed from scratch to integrate with the original chassis and body. The 400V drivetrain uses a Tesla Model 3 unit rotated and re-geared to deliver permanent AWD through a torque-biasing diff. A single front-mounted 55 kWh battery pack in a 3 mm steel enclosure feeds the system, with CCS2 delivering 70 kW DC fast charging and 6.6 kW AC charging.

Compliance to ADRs was engineered in: steering torque, braking distance, belt anchorage, crush strength and electrical isolation were all tested. The full vehicle was re-wired using CAN-connected PDMs and solid-state fusing, allowing precise control, diagnostics, and data logging.

Vehicle assembly uses a repeatable bill of process - with jigs, laser-cut brackets and CNC-finished parts. Battery packs and wiring looms are pre-assembled, reducing time on vehicle. The process enables repeatable builds in Jaunt’s Melbourne workshop while keeping costs and time down.