The vision for AE Hardware springs from a critical review of current artwork-handling practices, uncovering a clear need for a vastly improved ‘best-practice’ system spanning the entire process of art handling. Key risk points were identified across every stage of handling - from packing to installation - and these informed a five-year program of design, prototyping, and testing.

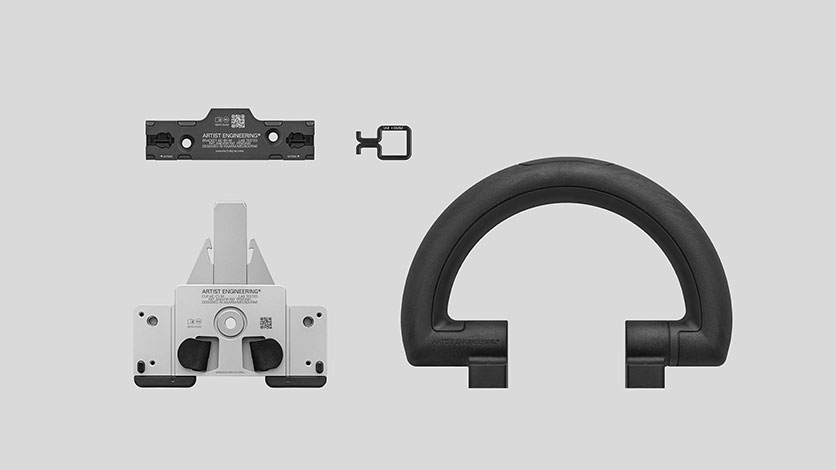

Practical workshops were conducted with curators, conservators and technicians, validating the concept of a fully integrated system and leading to an integrated function set that provides for all aspects of non-contact handling: storage; crating; shipping; staging and installation - using just three core components.

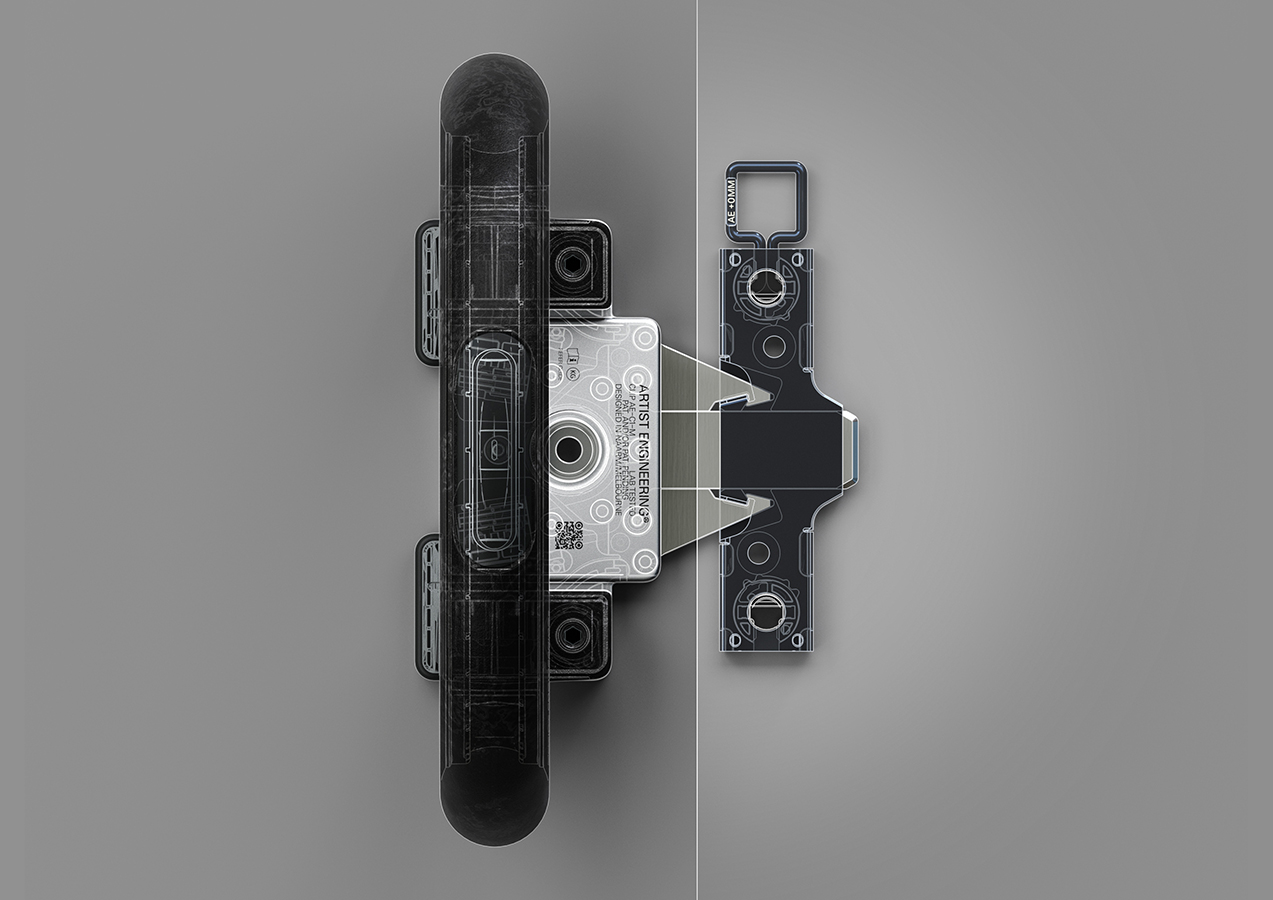

One by one, shortcomings in current art-logistics practices were addressed and concepts tested in collaboration with art technicians to validate performance under real-world conditions and ensure intuitive use in the field. Feedback led to refinements in ergonomics, tolerances, and visual design, resulting in a system that is intuitive to use and robust in operation.

Components were meticulously refined against artwork sizing, shipping and installation constraints, and materials were specified for performance and archival stability. Prototypes were rigorously tested in lab and practical environments, to ensure infallible performance.

The final solution reduces risk, simplifies logistics, and integrates seamlessly with standard crating and hanging systems. The design aims to set a new professional standard, with precision-machined parts, integrated safety features, and high-grade materials selected for long-term use.