With a keen interest in medical technologies, particularly neonatal medtech, this project began with a deep dive into hospitals through interviews with paediatric doctors and nurses. This phase of discussions and academic research uncovered a variety of problems needing solutions. For an industrial design-based project, the lack of innovation and technology in jaundice care provided the most room for a truly impactful solution.

Given the clinically proven methods for blue-light treatment, great emphasis was placed on creating a manufacturable prototype that could theoretically provide jaundice treatment. Additionally, the requirements outlined by UNICEF for jaundice therapy set clear goals for the project. These guidelines helped define the project’s objectives.

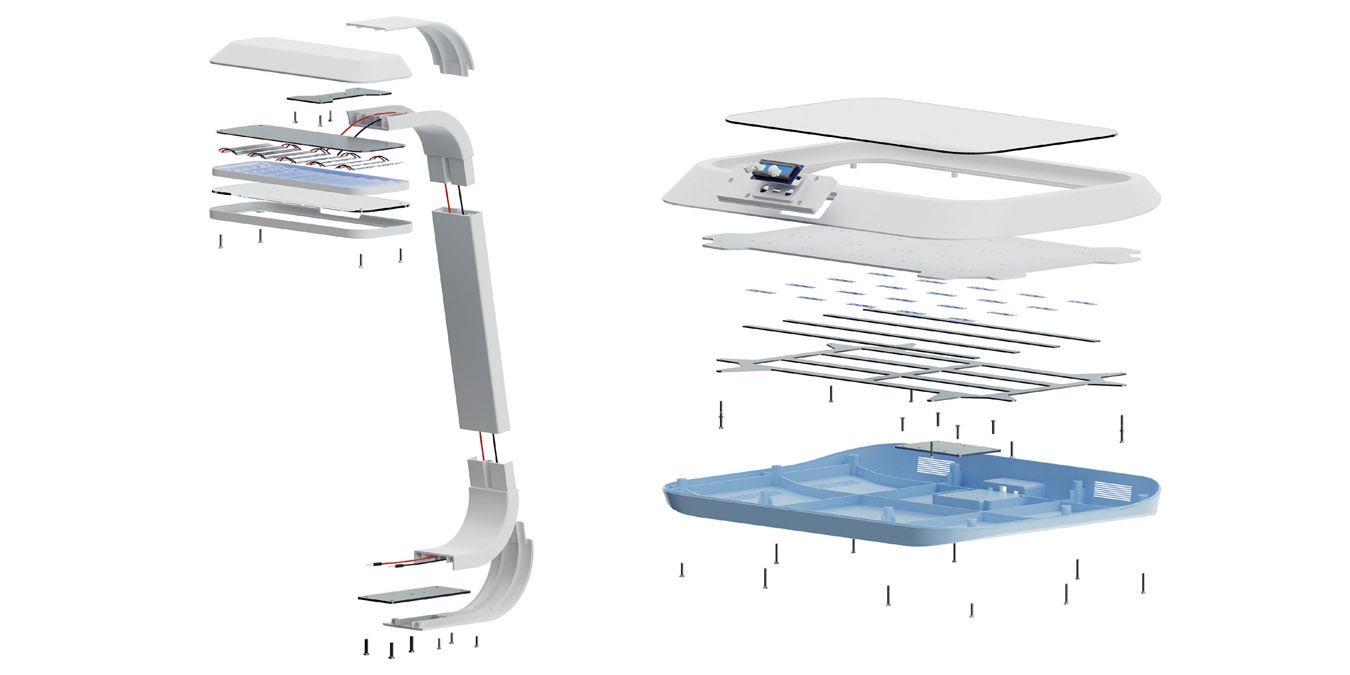

Classic design methods such as journey mapping, interviews, and ethnography were implemented to explore the potential forms the final product could take. This knowledge was then translated into the design and engineering of the product. 3D printing was used extensively, along with rapid electronic prototyping platforms like Arduino. A cyclical process of designing, prototyping, and consulting with medical professionals helped to guide and improve the product.

Every iteration of the design aimed to answer specific questions, such as the optimal implementation of electronics or the ideal dimensions for ergonomics. These iterations were presented to design and medical professionals weekly to gain insights and refine the design. This process was repeated until the final prototype met the criteria and guidelines defined at the start of the project.