RESEARCH

Research included interviews and site visits to learn from outdoor gear makers and repair people, benchmarking of existing gear and materials, and a bodystorming exercise along the Gariwerd Peaks Trail. I conducted multiple overnight hikes with nine fellow participants to understand the specific needs of hikers in the dark.

ITERATION

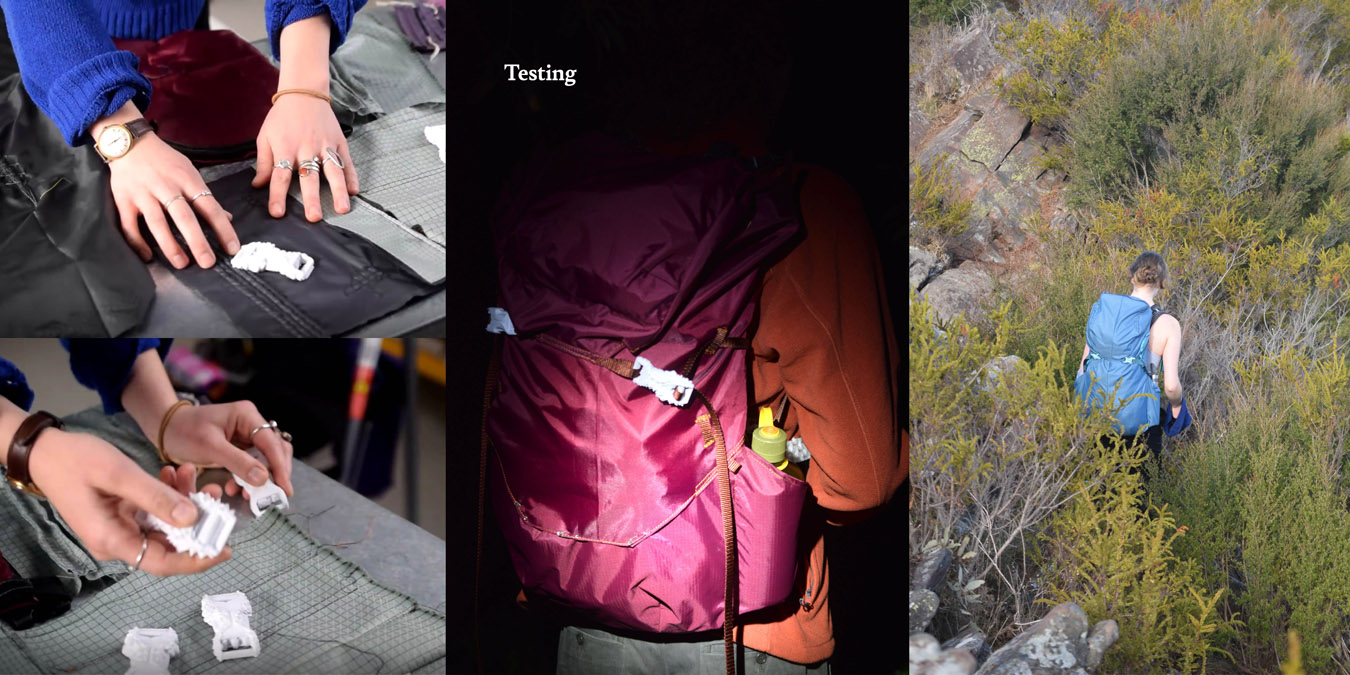

Once I had identified the opportunity for tactile surfaces, the iterative design process began. The combination of soft and hard materials in a hiking pack provides fertile ground for experimenting with both malleable and rigid textures. Using UX and wayfinding principles, alongside human touch-sense research, I applied these principles onto the surfaces of both hard buckles and soft, technical hiking textiles.

Paper prototypes and fabric tests were done using both physical craft and CAD-based techniques. I experimented with multiple techniques to land on a texture system that was identifiable, while also being durable and lightweight, the two main concerns of hikers choosing a pack to use.

TESTING

User testing, including indoor tests and outdoor hikes, was carried out to validate and iterate on the outcomes. Five participants were blindfolded and asked to evaluate a range of textured samples. I then conducted a nighttime test to simulate actual use cases of the product. Finally, the hiking pack and stuff sacks were taken on a six-hour hike at Cathedral Range.

PRODUCTION

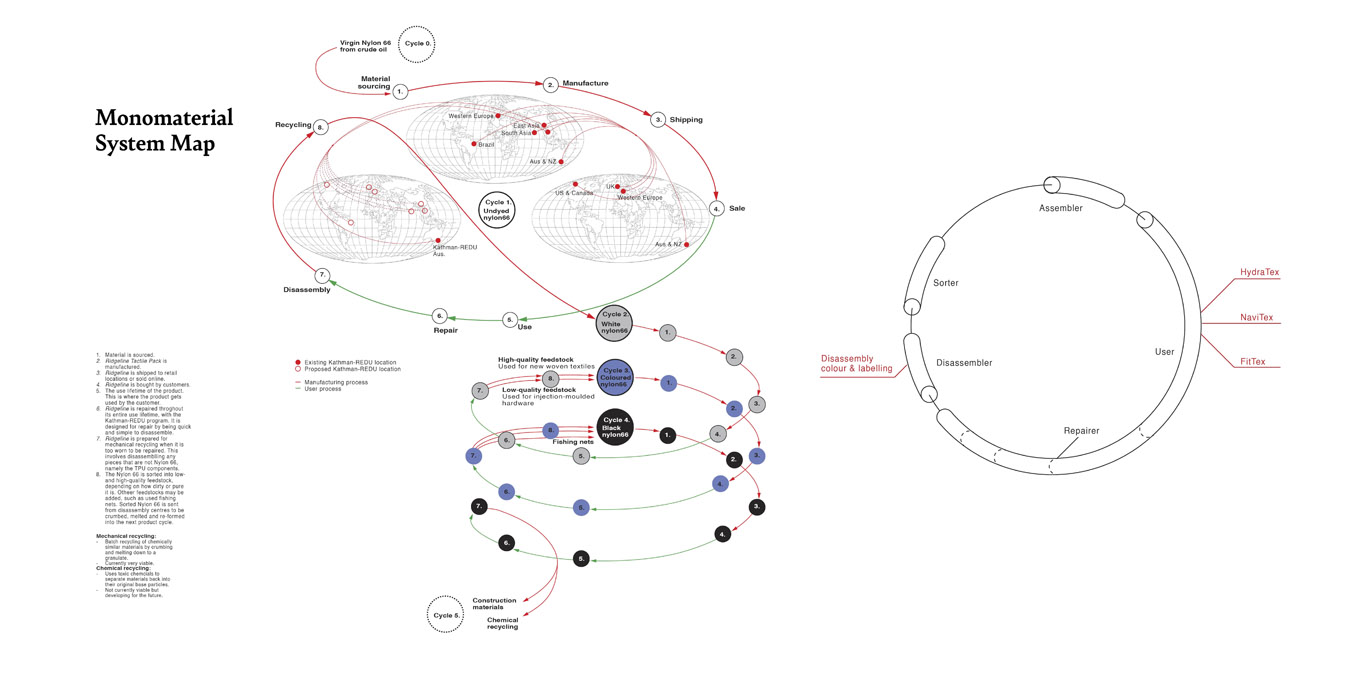

The Ridgeline Tactile Pack was produced using an industrial sewing machine to ensure a highly durable outcome. The tactile hardware was printed using a powder printer, and the frame was made of steel rod. The fabrics used are industry-leading nylon-66, creating a top-quality monomaterial construction. The outcome is conceptually the first of its kind, while also being designed for repair and disassembly, and could feasibly be manufactured with minimal changes.