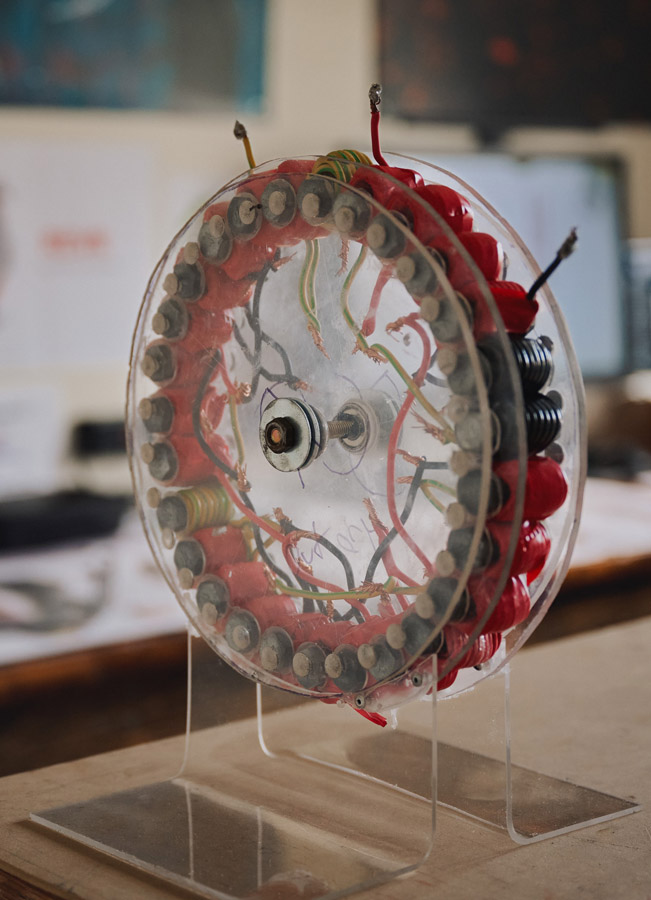

I started from knowing nothing about motors, but I had a passion for CAD and tinkering so I took it on as a personal project during COVID. There is not much space inside the car so I focused on the large internal cavity inside the car wheels since this also does not vary too much between makes and models. After lots of research I stumbled upon an axial flux motor concept invented in 2009 called YASA used in a Rolls Royce airplane. I started my design from a small in-wheel hub motor and Iterated from there in Fusion 360. I employed freely available research magnetic flux modeling packages FEMM and MOTORXP and performed finite element analysis over hundreds of iterations to get to my final design. I underwent hands-on dimensions prototyping on my car to better understand how the motor could be installed. This included making a smaller motor using the same winding scheme from home wiring cable to validate the design. Many components used 3d printing and cnc technologies available at my university. Some components of the motor had to be manually melted and cast in copper from CAD shapes using lost-wax casting for me to remain in my budget. The key design constraint was size and cost-to-build, I wanted to use as many OEM parts as possible and limit CNC machining.

REVR

Rapid Electric Vehicle Retrofit (REVR) is a new way to convert petrol vehicles to hybrid electric quickly and cheaply.

Rapid Electric Vehicle Retrofit (REVR) is a new method for converting internal combustion engine (ICE) vehicles into hybrid electric vehicles (HEVs) that offers significant cost and time savings. REVR is designed for commuters who are facing increasing fuel and maintenance costs and want to reduce their emissions. Our custom motors provide direct drive benefits of high efficiency and low weight while taking only minutes to install with zero specialist knowledge.

Design Brief:

ICE vehicles are responsible for over 20% of global emissions. Commuters are seeking alternatives such as EV’s but they are too expensive and have considerable emissions impacts from their manufacture, similarly existing public transport is inadequate for most. The existing 1 billion + fleet of ICE vehicles are perfectly functional and fit for purpose. Retrofits retain the carbon invested in ICE cars and do not require a new carbon debt for a new car. Car retrofits for electric drive are not widely available to the general public and the present approach of replacing the entire drive train is slow and expensive. REVR needed to overcome the challenges that have prevented retrofits achieving widescale adoption, namely cost and complexity.

This project was developed by:

Design Process

Design Excellence

This project started with a desire to convert an old toyota corolla affordably. Existing services are $50k+ adventures that take up to a year to complete, mostly being ’restomods’ targeted at classic vehicles. In-wheel motor technology is the least invasive retrofit approach. For this reason a YASA (yokeless Axial segmented architecture) topology was chosen for its unmatched power and torque density. Over several years the REVR motor was designed to produce upwards of 700NM (peak). This is high enought that gears and associated heavy wearing components can be removed. Cars require little to no modification making this a bolt-on hassle free conversion system, Since little specialist knowledge is needed installation by consumers is possible for a low-voltage hybrid conversion. The REVR control system is built on a opensource hardware and software worldwide initiative VESC for continuous and rapid performance improvements. The battery pack is built from lifepo4 cells which enable fast charging and discharging as well as extended lifespan and safety with reduced cost (the price of lifepo4 has plummeted over previous 2 decades). Since converted vehicles contain large 10kwh batteries they can also participate in upcoming schemes like vehicle to grid (V2G) to maximise battery utilisation.

Design Innovation

REVR innovates on this premise with the fastest theoretical conversion time of any system. When installed on recent petrol vehicles plug and play hybrid functionality can be achieved at 1/10th the current cost of a full electric conversion ($50k). Two ultra-high torque patented axial flux motors bolted into the rear wheels providing over 700nm of direct drive torque and 100kw of power (voltage dependent). Leveraging advances in motor, magnet and battery technology as well as proprietary motor and mechanical design a low cost, rapid rollout technology can greatly reduce our transport emissions today. REVR is sustainable, minimum materials consumption with large carbon benefits, carbon credit capable. Our system is highly flexible and can be adapted to almost any application requiring ICE to be augmented or replaced with electric traction. Our systems can be installed with minimum specialist knowledge, those who are in need of work are our prime target for installation labour, immigrants and handy individuals can be empowered to contribute to the community by installing and using our systems. Reducing our dependence on fossil fuels will boost the economy and provide economic value, almost all Australians rely on transport for their livelihoods, REVR reduces transport cost and environmental impact.

Design Impact

Most people are still buying MORE and LARGER petrol vehicles (UTES & SUVS). Even with EV sales slowly growing we are making little improvement in emissions. Yearly fuel costs are rising and eating out of Australian budgets. Even new EV purchases require massive amounts of material and effort, emmit huge amounts of GHG during manufacture and delivery whilst remaining cost prohibitive for most. Old vehicles have already paid off their carbon debt and have decades of usefulness remaining. There are over 1 billion of them and they are continuing to be bought. Replacing these in the time needed to avert climate change is impossible. Retrofitting achieves the same or higher carbon reduction as conversion to EV without the waste of replacing the entire vehicle. The limitation of retrofitting has been mainly cost, as a result of full electrification being an incredibly complex and time consuming process that varies greatly across car models. Over 80% of the emissions and cost benefits of full electrification can be achieved with a small footprint hybrid approach. The benefit of this is reduced complexity of the conversion as much of the vehicle can remain unmodified, thus most of the existing value of the vehicle is retained.

Circular and Sustainability Criteria

REVR may help retain mechanic workshops working and employ thousands across Australia, open new manufacturing jobs, precinct, reduce costs for commuters/workers. Retrofits reduce tailpipe emissions of ICE vehicles by 70-100% (depending on retrofit config) cheaply and quickly with minimum manufacturing emissions and cost and equitable access. REVR will allow for rapid transition to electric by facilitating a smoother transition process from ICE to electric and higher EV update at end of life. This is because the retrofits will demonstrate the petrol savings, improved car power, reduced noise, reduced emissions and reduced maintenance costs of eleric vehicles at considerably lower cost.

Meet the Jury

Entries are judged by a panel of national and international design experts representing the diverse range of design disciplines showcased by the awards.

View the Awards JuryEntering the Awards

The Awards are free to enter for eligible Victorian designers and architects with submissions across eight design categories.

Learn more about the guidelines and processType on the line above then press the Enter/Return key to submit a new search query