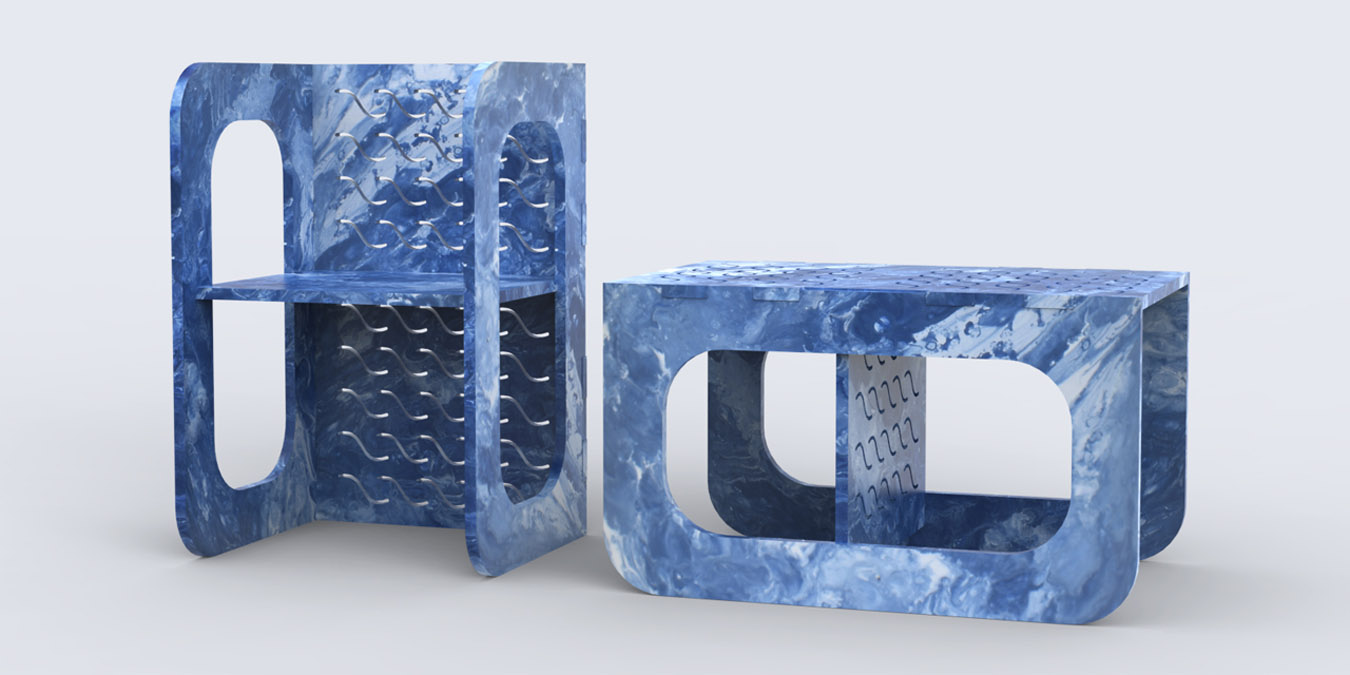

The design process involved a comprehensive and professional approach to meet two distinct briefs. Initially, ideation sketching was used to brainstorm and refine concepts where the focus was on creating a chair that meets ergonomic standards and accommodates a wide range of users. Key features like dual seating heights and a wider seat were incorporated to enhance comfort and functionality, and the chair’s multifunctionality extends to transforming it into a table.

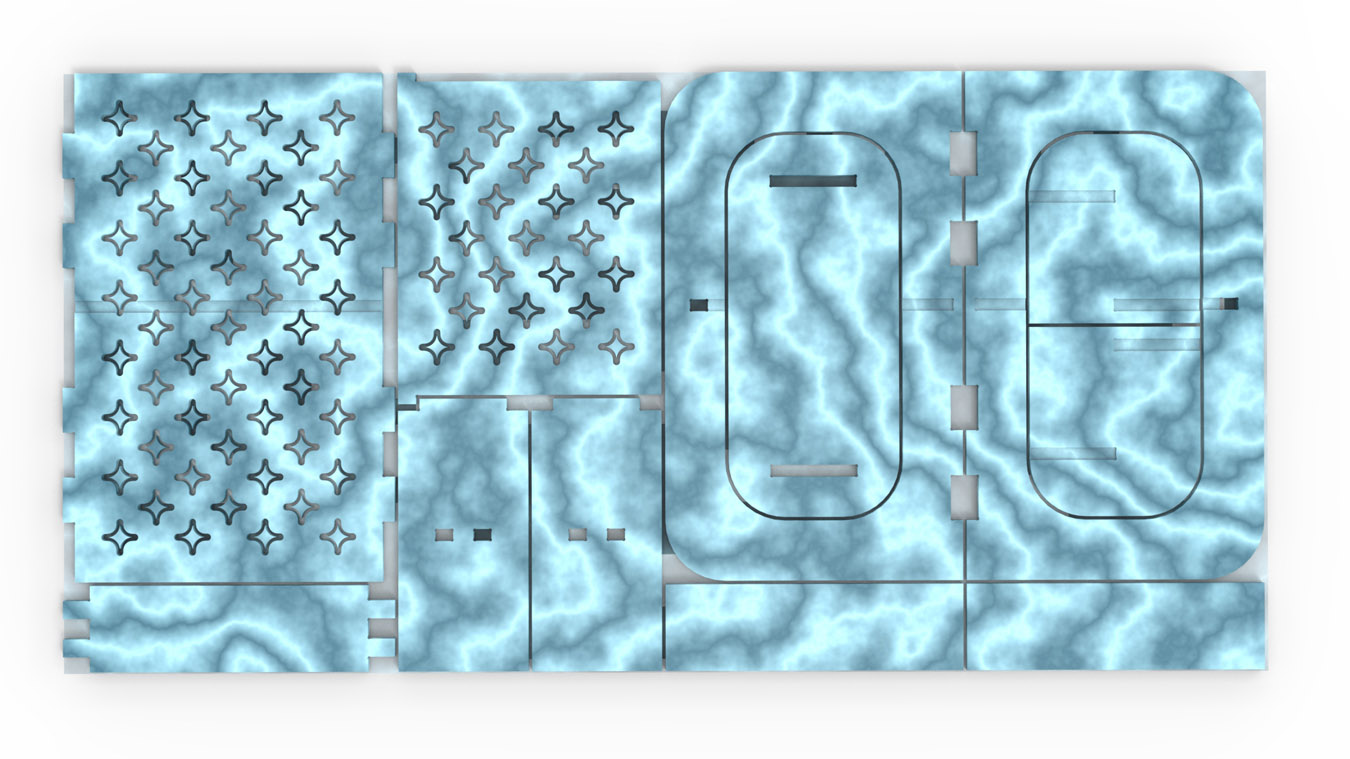

Next, 3D modelling was used to visualise the chosen design. This step was significant to ensure the design efficiently utilised the plastic sheets. The design was meticulously restricted to ensure efficient nesting of parts to minimise waste. Research was conducted on various joints and patterns to enhance the design’s integrity and ease of assembly.

Prototyping began with 3D printing a swatch of a part of the chair with the Kawung-inspired pattern to test its structural integrity. Feedback was sought through presentations to peers, which helped refine the design further. A full-scale prototype was then constructed using plywood, allowing for detailed assessment and adjustments to the assembly process. This stage ensured the joints were sturdy and the construction process was smooth.

The design was selected to be prototyped in Indonesia through collaboration with Precious Plastic Bandung. Here, the furniture was produced from locally sourced waste plastic. The Kawung pattern on the chair worked as a connection between local culture and broader environmental themes. In the final stage, the chair design was adjusted to allow for even easier assembly and a new wave pattern. This new pattern not only represents the waterways from the rivers in Indonesia to the shores of Australia but also reduces plastic waste during production by requiring less cutting and eliminating offcuts.