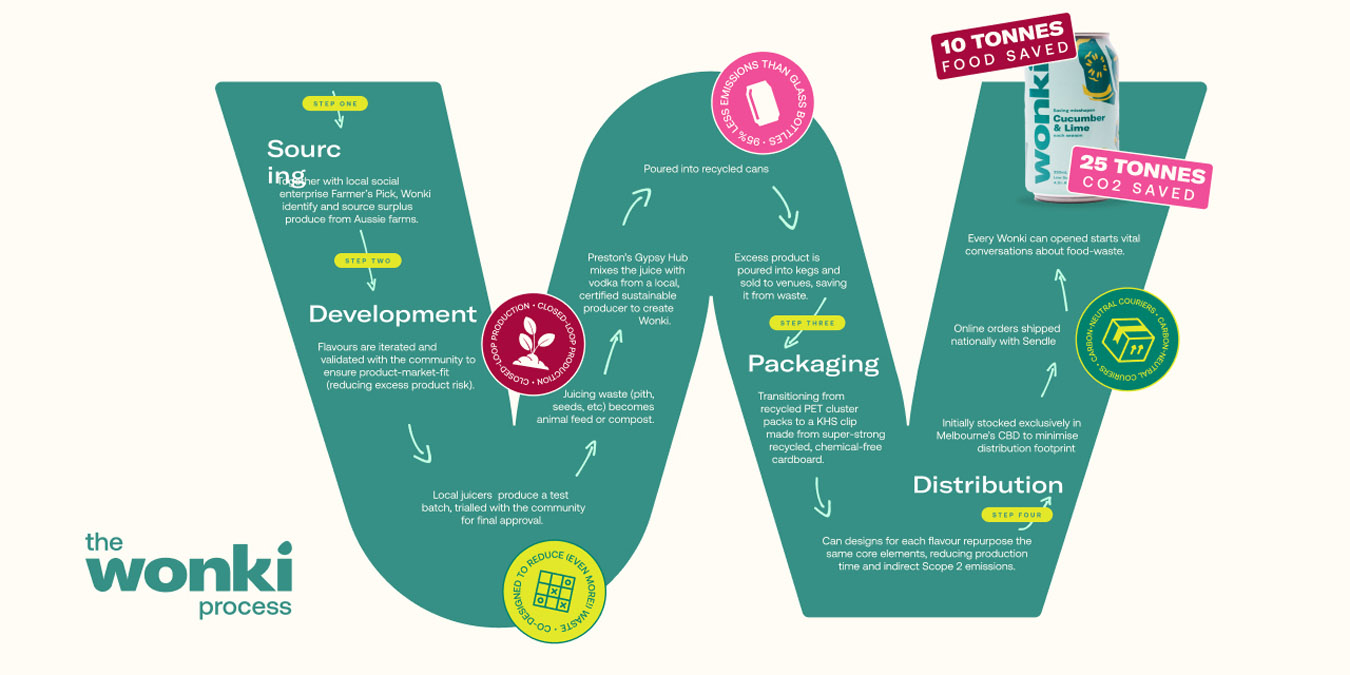

Wonki’s design features extend beyond the beautiful brand into a consciously-created product with sustainability at every step.

Sourcing:

Together with local social enterprise Farmer’s Pick, Wonki identifies seasonal surplus produce from Aussie farms that require timely saving.

Development:

- Flavours are iterated and validated with the community to ensure product-market-fit (reducing excess product risk).

- Local juicers then produce a test batch, trialled with the community for final approval.

- Juicing waste (pith, seeds, etc) becomes animal feed or compost in a closed-loop.

- Preston’s Gypsy Hub mixes the juice with vodka from a local, certified sustainable producer to create Wonki.

- Poured into recycled cans (95% less emissions than glass bottles).

- Challenge: Variable juice yield - excess product is filled into kegs and sold to venues, saving it from waste.

Packaging:

- Initially cluster-packed using recycled PET, Wonki is transitioning to a KHS clip

- Made from robust cardboard removing the need for toxic ‘wet-chemicals’ which prevent effective recycling.

- Wonki’s can designs for each flavour repurpose the same core elements, reducing production time and indirect Scope 2 emissions.

Distribution:

- Initially stocked exclusively in Melbourne’s CBD to minimise distribution footprint.

- Online orders shipped nationally with Sendle a carbon-neutral courier.

- Every Wonki can opened starts vital conversations about food-waste.