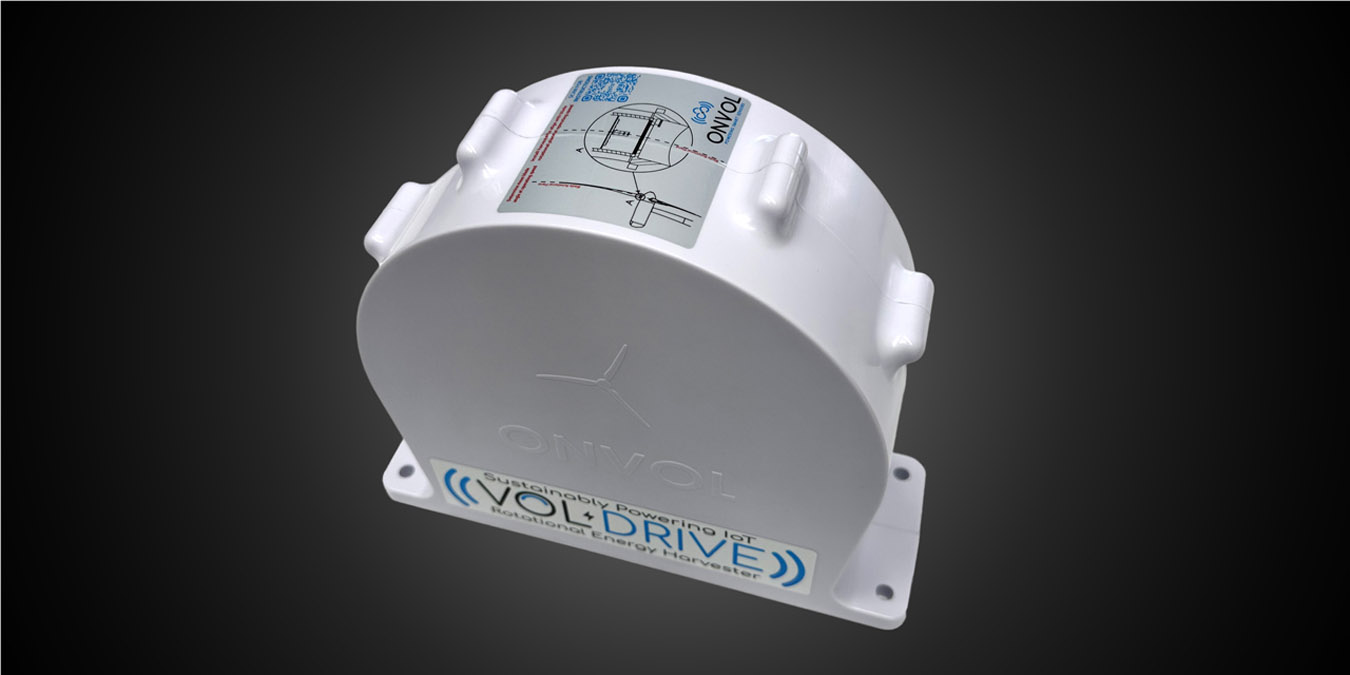

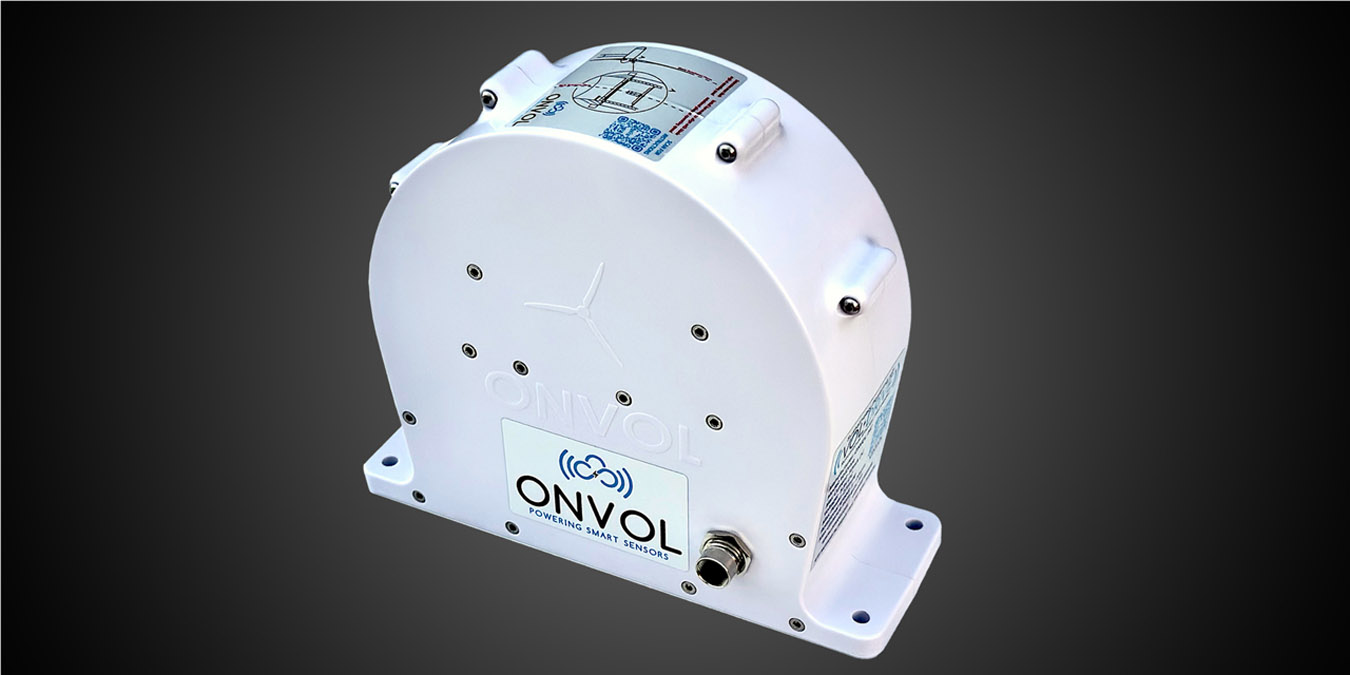

VolDrive is a groundbreaking kinetic energy harvesting solution standing as a testament to design excellence. Our comprehensive approach focused on multiple facets of design, ensuring a holistic, high-quality user experience to create social impact.

Functionality and Accessibility:

We meticulously considered all parts of the product use journey to understand functionality in every aspect of operation, ensuring that our solution seamlessly integrates into existing processes and systems. Compatibility, ease of use and reliability were key priorities.

Extensive research and testing with customers like NextEra Energy, allowed us to understand operators’ needs and challenges. This assured a user-friendly, intuitive design that enhances usefulness and ease of use.

An earlier superseded design in VolPower, was subjected to extensive real-world testing and customer feedback dictated vast improvements in the design of VolDrive. Reliability and functionality were enhanced by reducing 21 moving parts to just 1 and active power electronics that are state-of-the-art being having efficiency measured to nanowatts.

Aesthetics and Safety:

Our solution embraces sleek, modern aesthetics. Attention to detail in material selection and finishes elevates the visual appeal of industrial assets.

Safety measures were paramount. We adhered to ISO9001 design and development standards, prioritising the well-being of operators and users with RoHS and CE compliance.

Quality and Sustainability:

Quality permeated every aspect of our design. From execution to implementation, we ensured a sense of purity, integration, and efficiency. Through FEA the shape is optimised providing the lowest possible volume and weight design.

By harnessing clean, renewable kinetic energy, we eliminated reliance on traditional battery-powered sensors. This reduction in waste contributes to a more sustainable society.

User-Centered Design:

Stakeholder feedback guided our process. Operators, end-users, and other stakeholders provided insights that shaped our design.

Ease of installation, intuitive interfaces, and seamless integration were non-negotiable. We prioritised a positive and meaningful experience for all involved.