Our design process for this project followed Cobalt’s proven development steps tailored in this instance to collaborate with Bio-Rad’s California-based inhouse team. This brought together our respective technical expertise and shared aim for a well-designed, user-centred outcome.

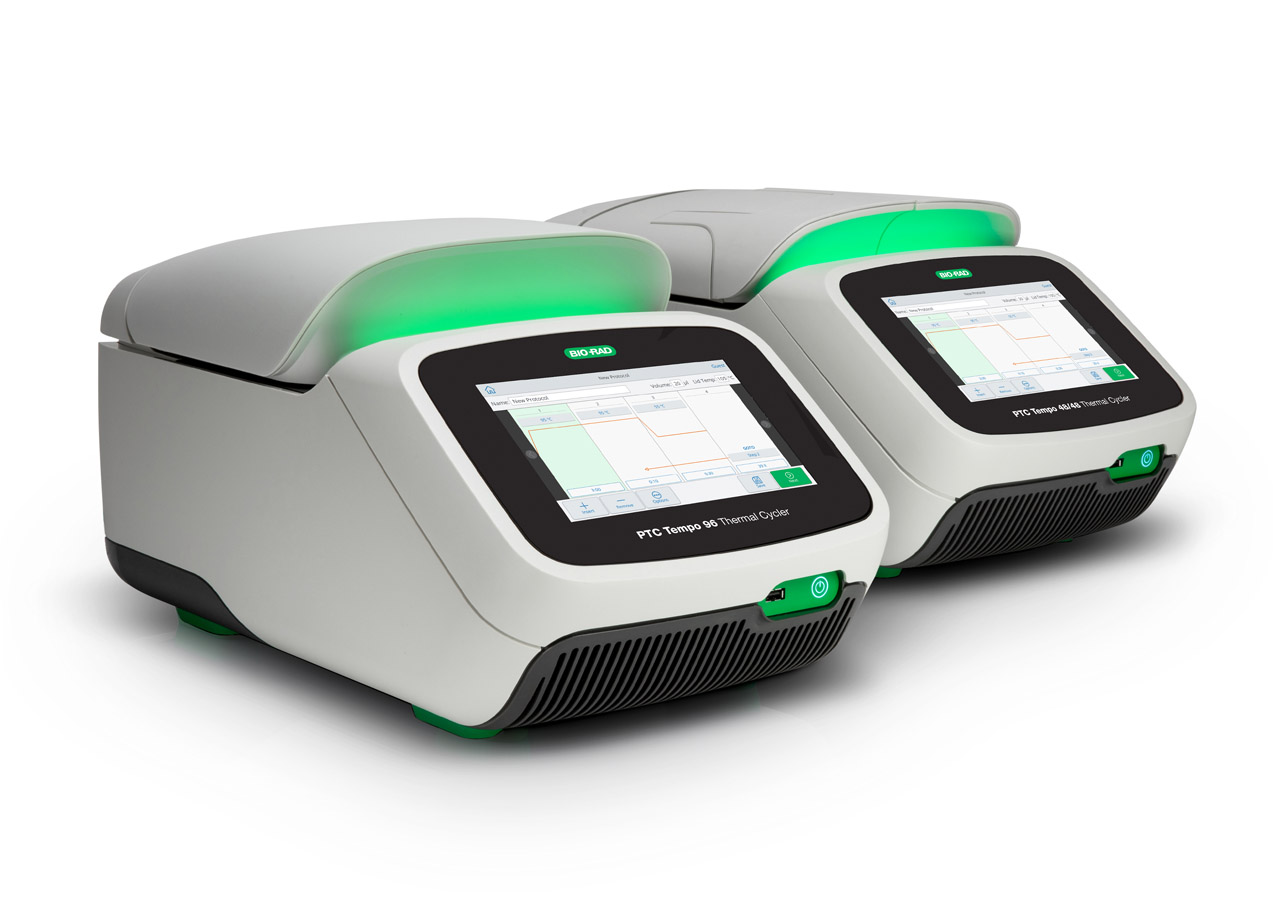

In several ways, the project met and exceeded Bio-Rad’s brief of a new-generation instrument that supported diverse workflows and lab types - one example being the unique hinge design developed and engineered ahead of the main design phase, as this informed the instrument’s overall dimensional profile and significantly widened its compatibility to different sample plate configurations.

Our process commenced with understanding and observing user needs with one of these being the premium of laboratory bench space. This drove several design decisions within the project and outcomes in the final design: minimal footprint, lower lid opening (allowing clearance to operate under low overhead shelving) and back-set mass, feet placement facilitating the instrument’s touch screen to safely overhang on shallow benchtops.

Despite being on different continents, the Cobalt and Bio-Rad project teams contributed their respective expertise and insights throughout the project with a collaborative and common focus. For example, Bio-Rad’s team was rightly determined to maintain their global-leadership reputation in PCR instrumentation. Key elements of the instrument’s architecture were jointly designed to maximise the benefits of Bio-Rad’s new reduced-mass sample block heating technology. In turn, this provided industry-high levels of thermal stability, which is a key determinate for accuracy and performance, as well as user-centric advantages, such as compact benchtop size and sample accessibility.