The “Revamped Double Diamond Design Process Framework” as approached by Dan Nessler in 2016, is the methodology I followed for the process of designing the SaferSaw. After intense research through a literature review and technical analysis, many ideas were considered for the redesign of tree cutting equipment. The research converged to a point that ideation could be conducted from. This point was the portability of chainsaws for building trails and for emergency services, as the bar guide on current chainsaws would protrude from any mounting device.

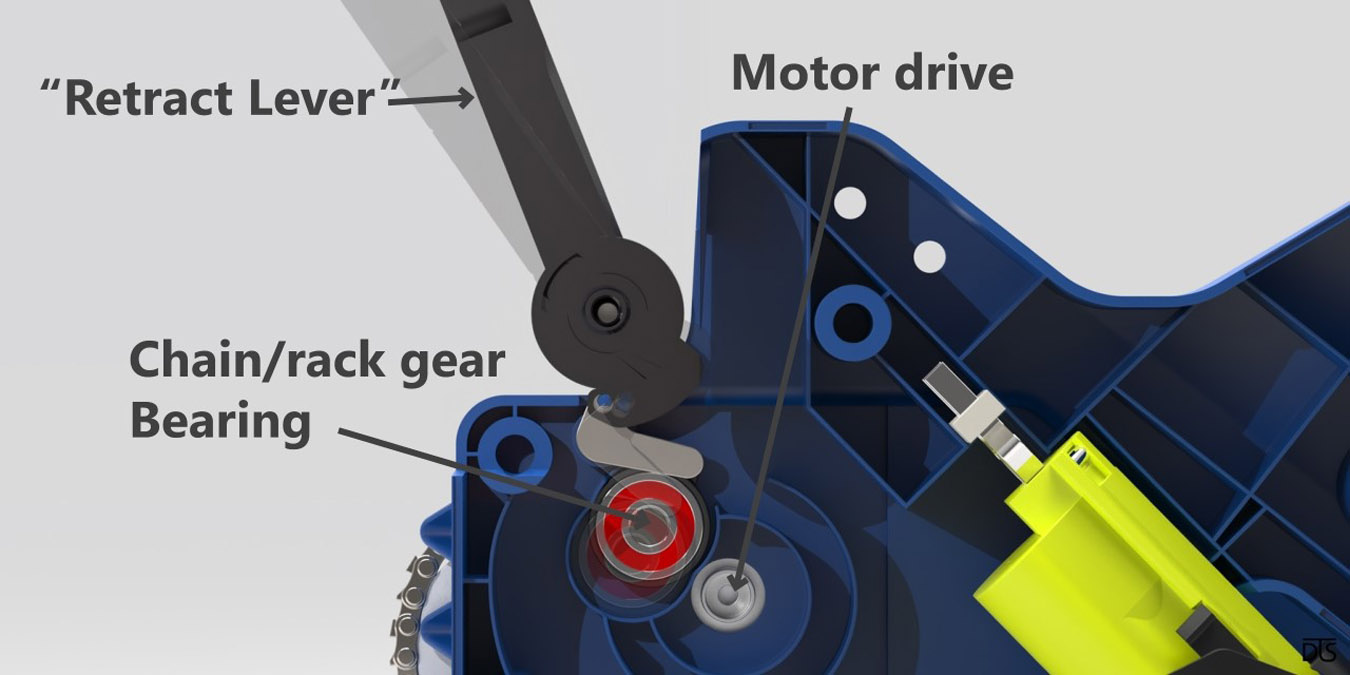

Many ideas diverged into different sectors of tree cutting services, where safety considerations became an important aspect of the design. Early concepts that stuck were based on the idea of a chainsaw with a moving bar. Both the retracting bar and a rotating bar design were further developed, as the concept of a bar that can be reduced in size would improve portability. It was then realised that kickback, a major injury risk related to the incorrect use of a chainsaw, could be eliminated with these same designs. Another strong idea considered was an exo suit concept that could help prevent kickback on current chainsaws. These three designs were put through a selection process matrix, where the SaferSaw featuring a retracting bar was chosen.

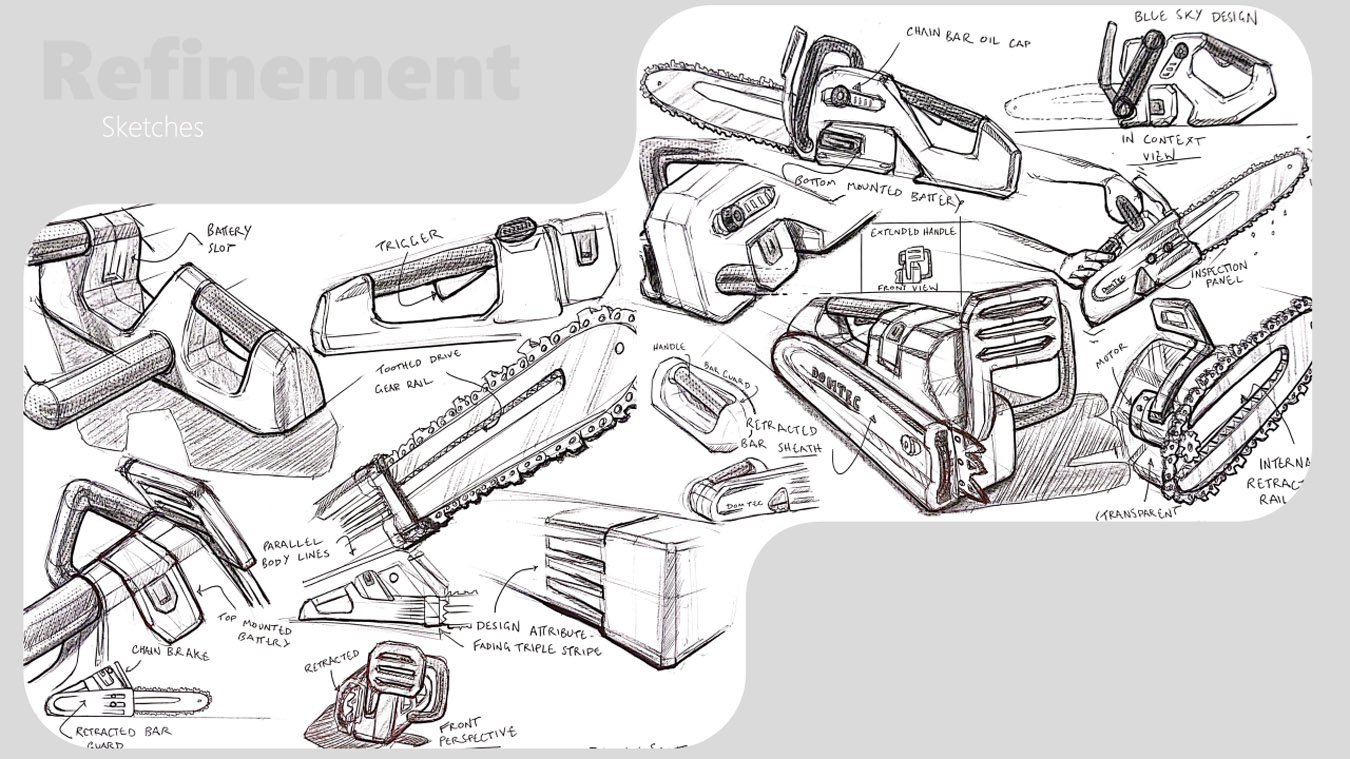

Design developments to be followed from this point include experimentation, form studies, ergonomic reviews, technical design, branding considerations, packaging considerations, form refinement and Engineering considerations.