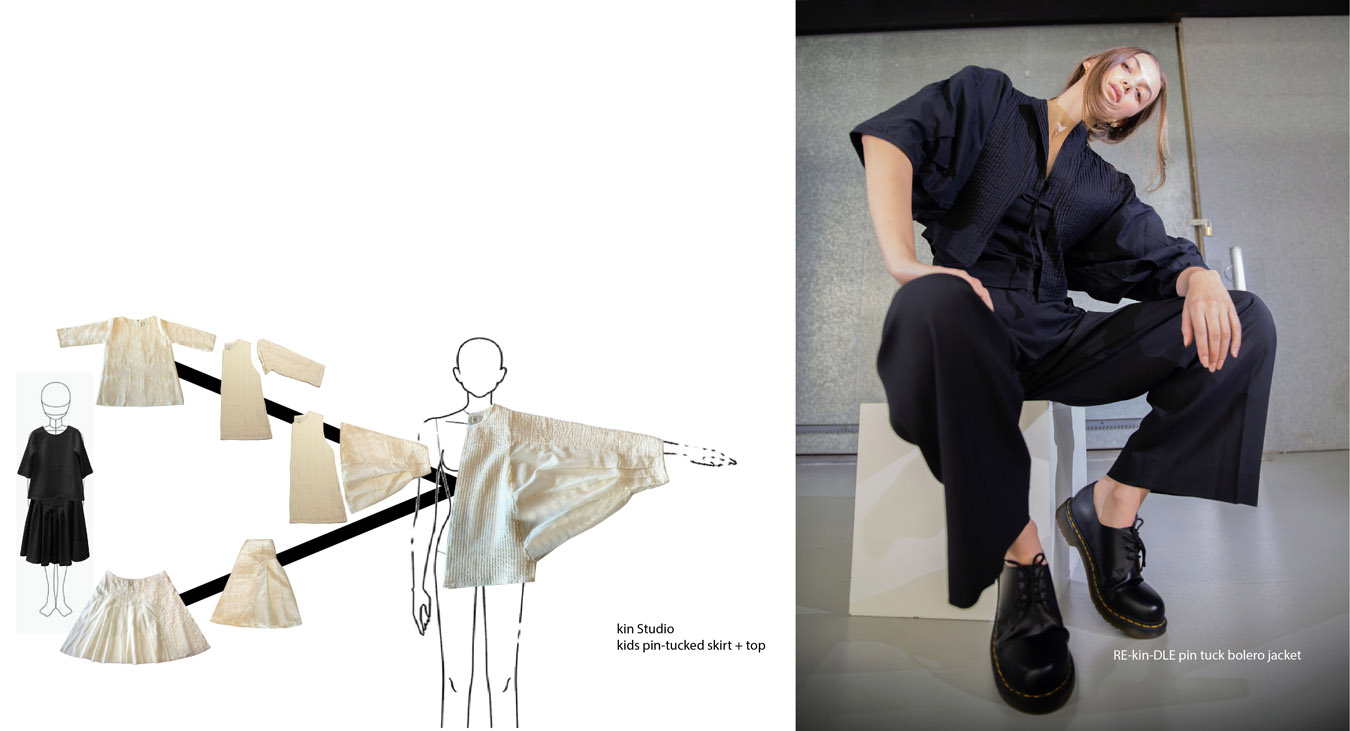

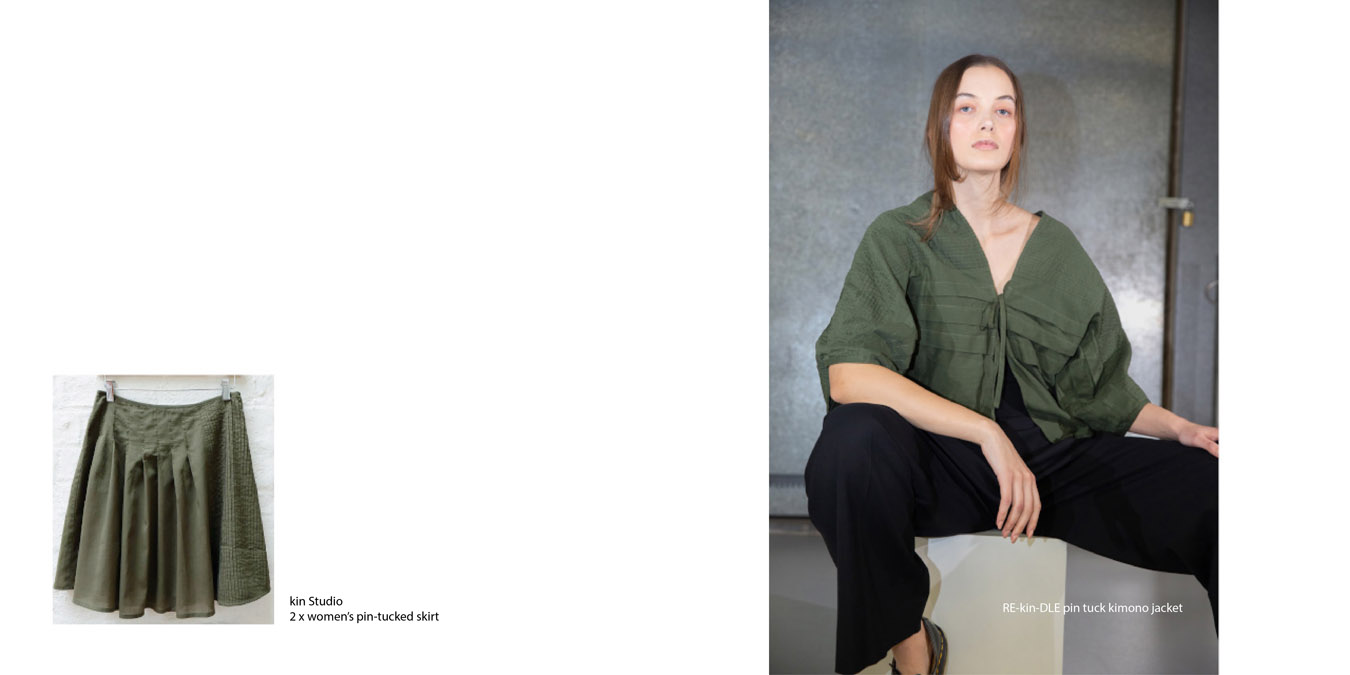

The first series of garments was remanufactured by transforming kin Studio kidswear into women’s garments. These items, originally part of mismatched sets at the end of the season, still maintained the high-quality standards of the kin brand, including Global Organic Textile Standard (GOTS) cotton, Supplier Ethical Data Exchange (SEDEX) production in India, and artisanal details like hand pin-tucks. The redesign process was systematically developed and documented to enable replication through standardised manufacturing processes. This reduced time-consuming interventions such as unpicking and recutting, and created templates for scalability, including assessment criteria and costings (see examples attached at end of application).

The second series of garments utilised excess stock from Country Road, building on the templates and systems developed at kin Studio. These garments were chosen based on identifiable flaws that hindered sales, as indicated by online and in-store feedback. Various techniques were employed, including overdyeing, printing, laser cutting, and dis/reassembly (see example of process diagrams attached at end of application). The redesign process aimed to enhance the capacity within the Country Road team to develop circular strategies. This involved collaboration with their production, design, and marketing teams to coordinate the rollout of this pilot project.