This project began as a deep exploration of ceramic 3D printing and data physicalisation. Countless hours of print testing and prototyping was undertaken to discover the limits and hidden attributes of the method, such as intentional layer failure and translucency. Early developments converted hand movements into ceramic vase objects. Outcomes converted the gestures of music into physical objects, as well as creating an ink printing object which allowed the transmission of dance choreography. Over 12 months of research, it began to move from an experimental project into a more functional design outcome. A deep dive into parametric modelling, toolpath creation, and acoustic engineering simulation was undertaken.

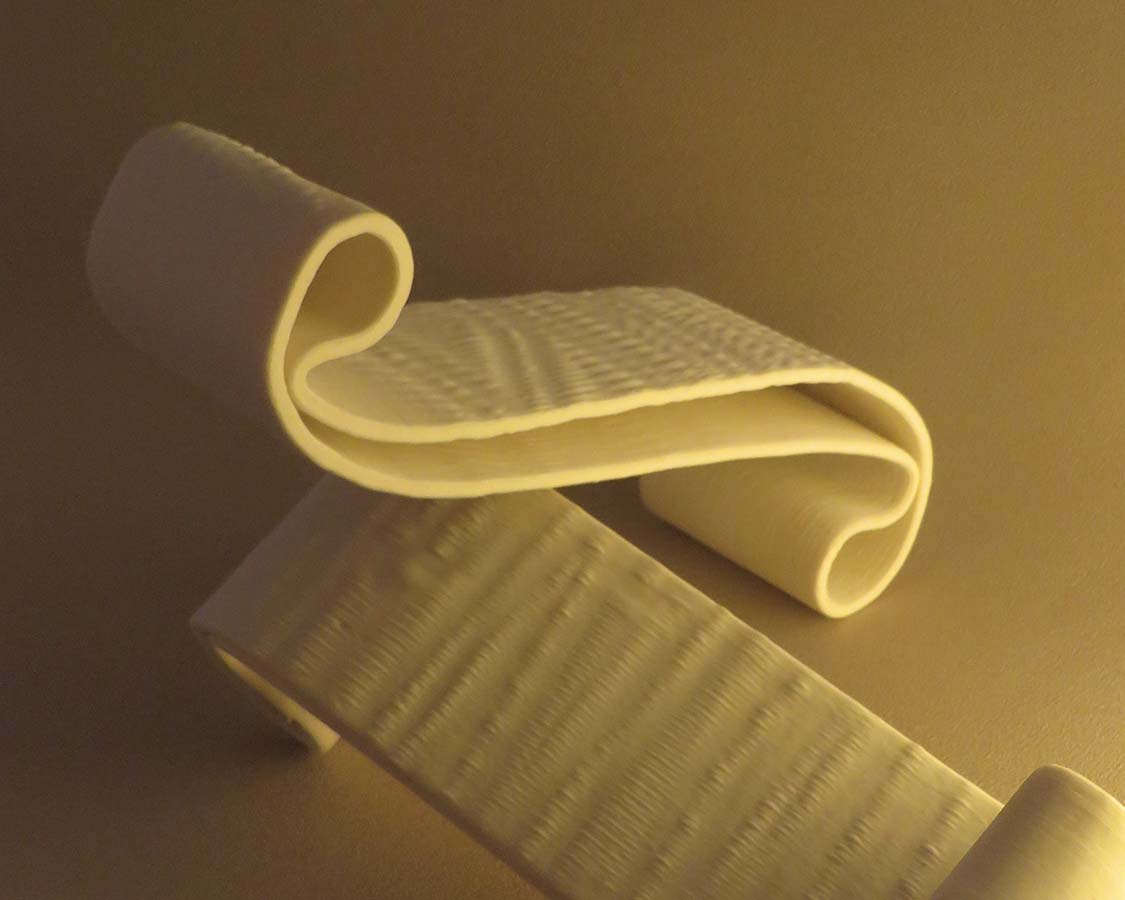

A final production process has been developed. First, a base tile form can be arrayed in order to fit the specific acoustic needs of a space. This can be modelled to calculate the theoretical impact this would have on the acoustics of a space such as reverb time. An inputted sound, recorded via spectrograph can then drive a generative script, creating a surface pattern on the desired array. The array is modelled and converted into separate print files (toolpaths), to be sent to a robotic printer. A specific clay preparation process has been developed for repeatability. Each tile is unique, creating an overall pattern. This overall pattern is a unique sonic fingerprint of the space in which it sits.