Applying professional design skills and plastics expertise we’ve engineered a novel mechanism, crafted a stylistically-considered, and functionally resolved product aimed towards tech-savvy shoppers.

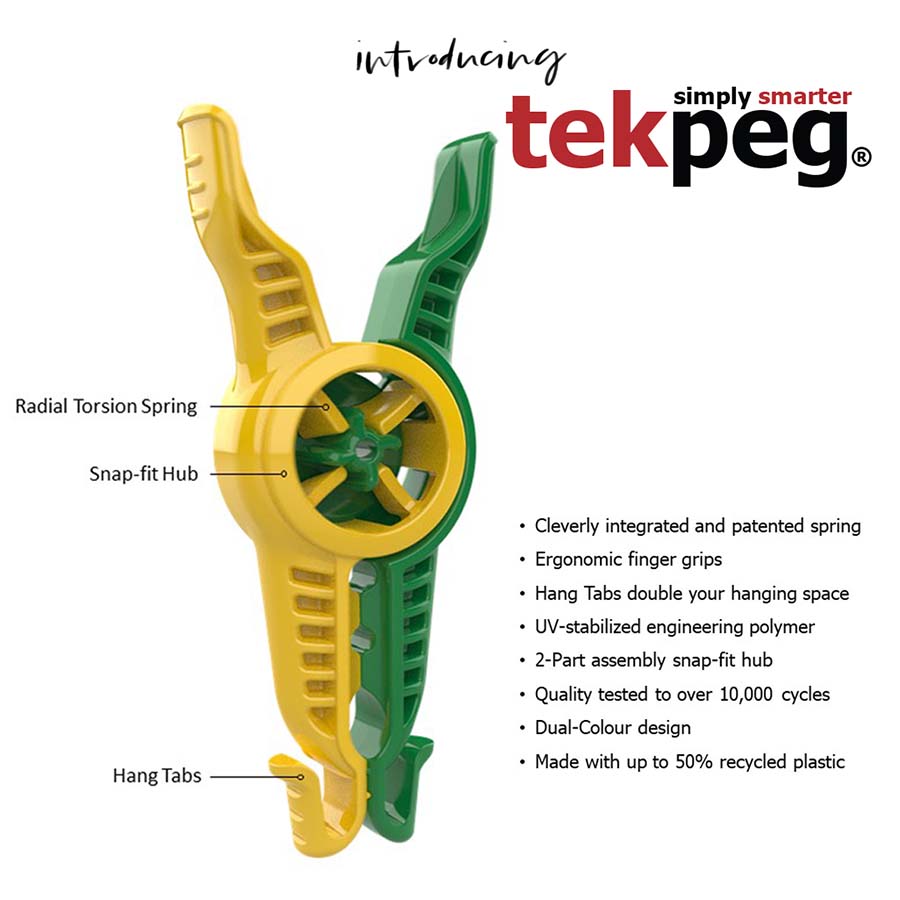

Form - The visual form intends to highlight the circular integrated spring hub as the centre piece of this new inventive step. The soft forms of the handles blend proportionally into the hub and continue maintaining strong angles and organic cues right down to the hang tabs which visually link back to the main body.

Function - The design enhances the user experience by visually celebrating the flexural properties of the plastic and giving the user visual and tactile feedback of the tension generated through the squeezing cycle.

Safety - Tekpeg® has been designed for a manual snap-fit process via x4 one-way clips which clip the two halves together. It cannot be easily pulled apart by the user and the design does away with industrial assembly machinery requirements.

Quality - Tekpeg® is a 2-part product. The Fin side does all the flexing and is made from an engineered polymer which consistently reverts to its nominal flexural properties and commonly used in the manufacture of plastic buckles. The hub side is a static part and not subjected to any mechanical loading.