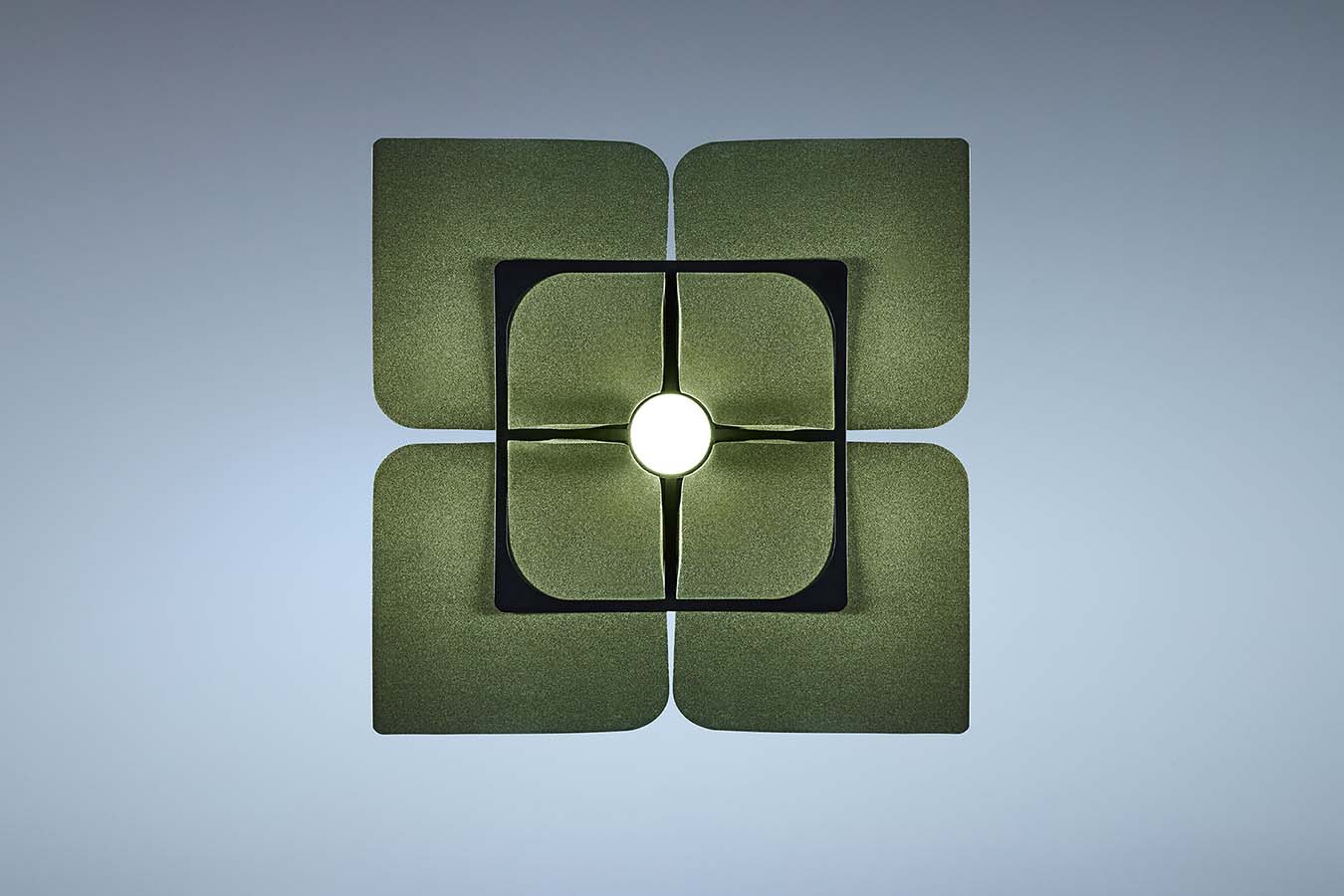

Our design process began by identifying customer needs, and sketching initial concepts. This initial stage involved much research and experimentation of the limitations of manufacturing and assembling our star material, the acoustic foam. The design team created prototypes to explore the foam’s soft, forgiving nature and incorporate this unique element into the design.

What followed was a year-long development cycle, comprising many iterations to reach the final product.

Because of the unpredictable nature of the foam, it was necessary to test its bendiness in relation to the other components of the product, which resulted in much liaison with manufacturers to perfect the tolerances to allow the foam to sit exactly level when hanging.

After finalising the design, we then began testing its longevity by hanging the product in a test room for an ongoing period, to observe how the foam performs over time.

Because the design comes as a flat pack, we also tested the user experience of assembly with a qualified electrician, in order to adjust potentially complicated operations or ambiguous assembly steps. After re-testing, we received positive feedback and results that indicated this assembly was simple to execute in under 10 minutes.