The long standing joint AS/NZ standard for roof drainage, AS/NZS3500.3 contained clear requirements and a range of graphs and formulas which plumbers were supposed to be using to design box gutter systems, however virtually nobody e.g plumbers, architects, building designers, builders, nor building surveyors, actually understood them, nor the processes required in the General Method of that standard to achieve a result that was conforming and compliant and actually worked in at least a 1:100 year storm event (the minimum performance standard set in Australia) so that they would not flood the building.

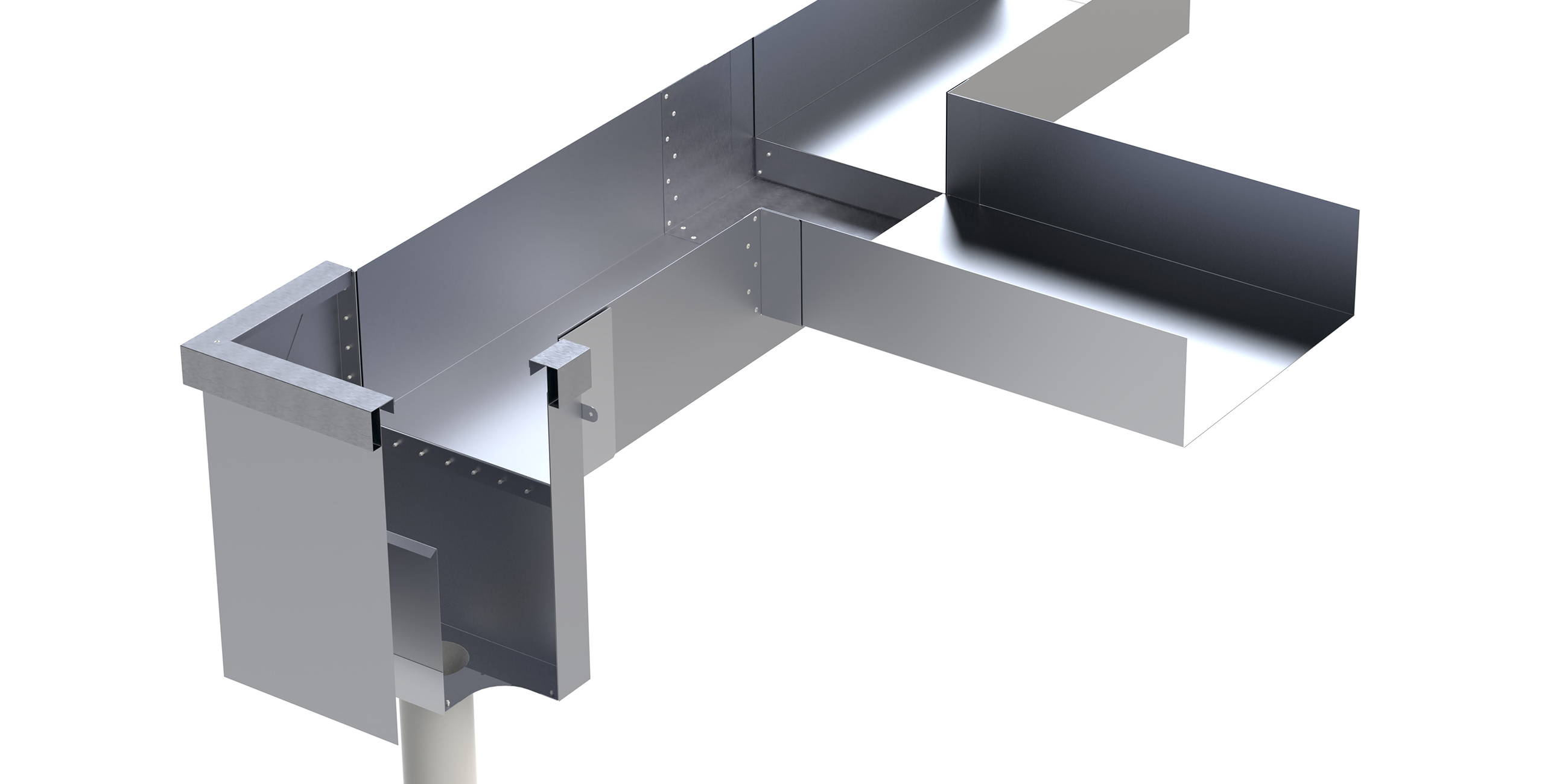

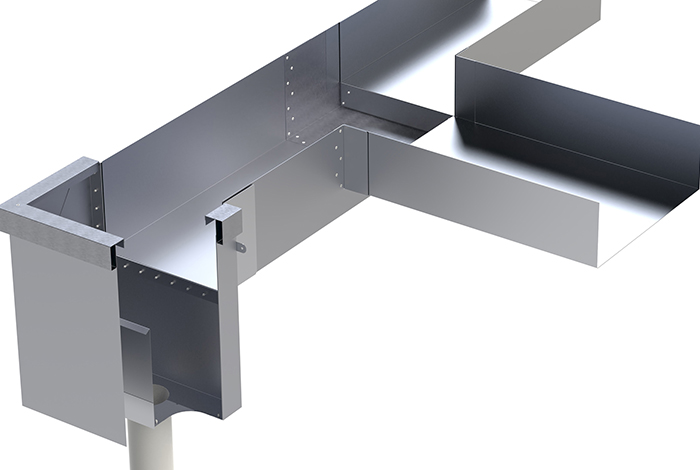

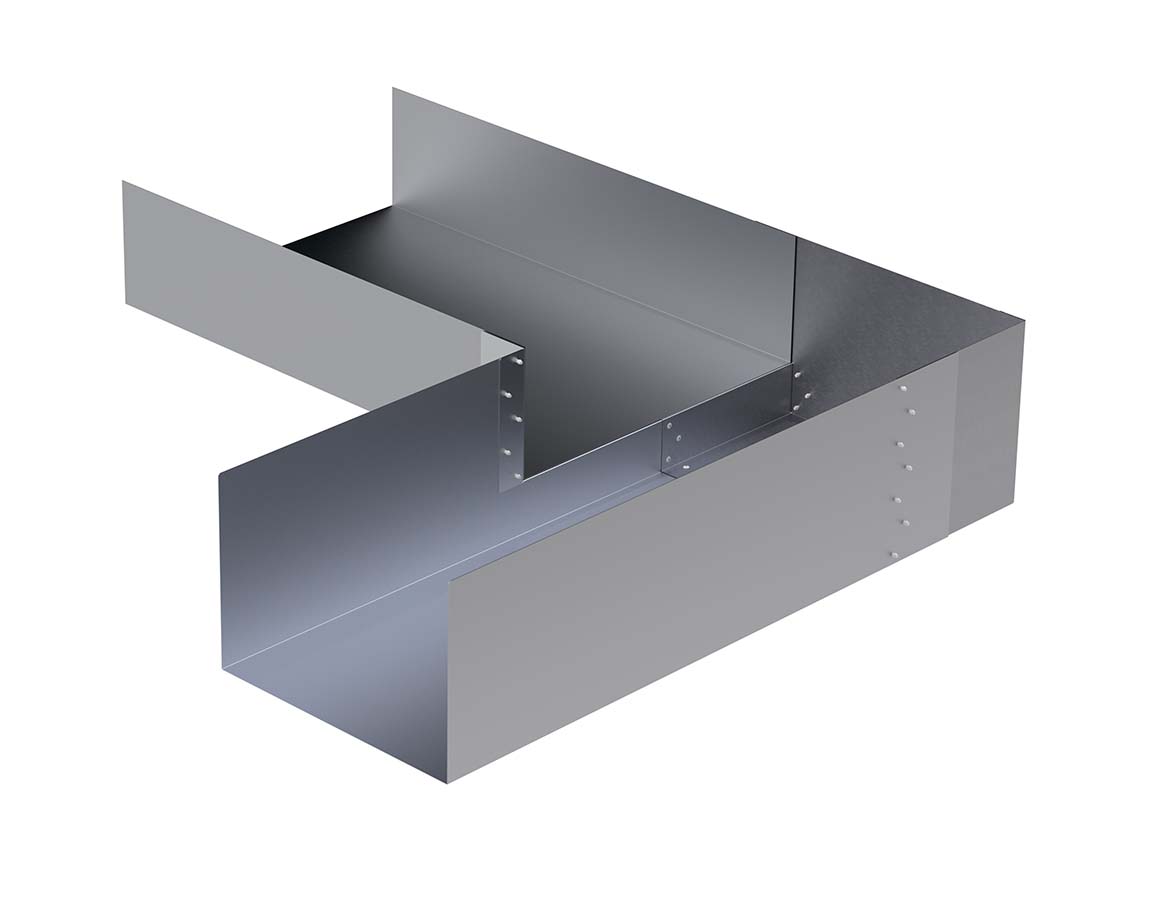

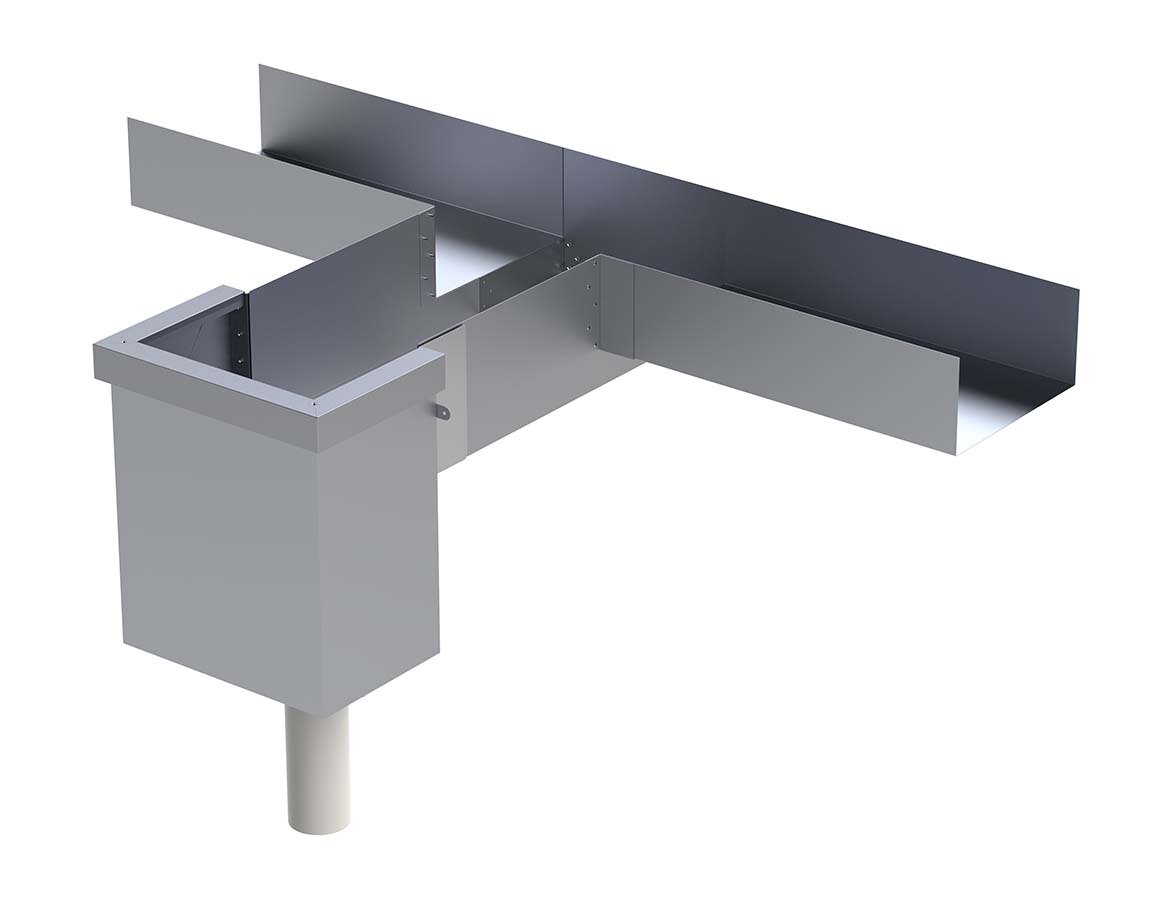

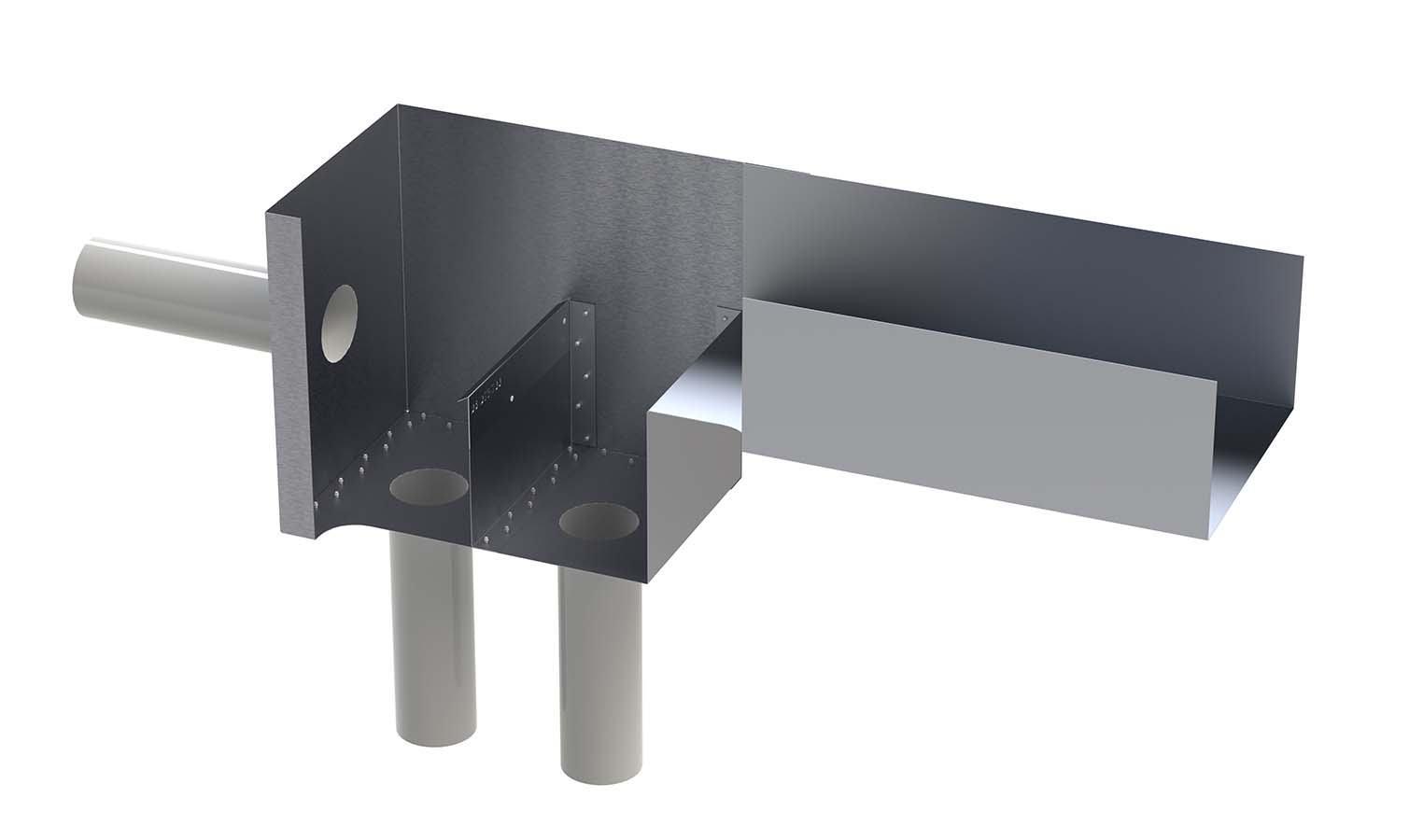

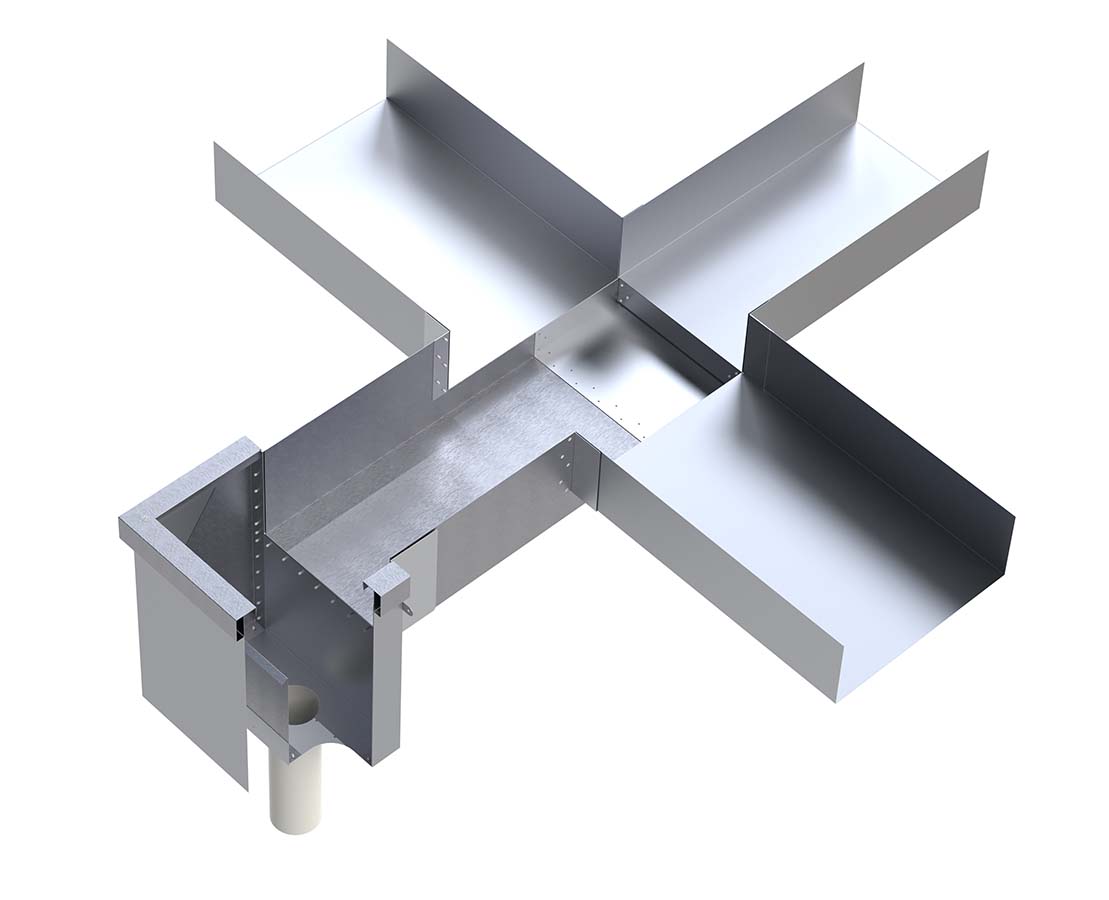

Dam Buster started by looking at the AS3500.3 requirements and formulas, then we reverse engineered them to create a range of products nobody had ever seen before anywhere in the world. The initial designs were developed over a period of several years and checked by two forensic civil engineers, then by several eminent hydraulic engineers, including two Professors of hydraulics, Associate Professor Terry Lucke of the AHSCS Research Foundation and also more recently, Associate Professor Robert Keller of Monash University.

The brief was fully met and actually greatly exceeded. The initial brief was one product, however the end result was a range of products for different uses, all deploying the unique "Free Flow" approach deployed by Dam Buster for the first time in a range of highly innovative ways. The uniqueness of this approach has in turn enabled Dam Buster to secure a range of Australian and international patents on the products, including also in the USA and NZ.