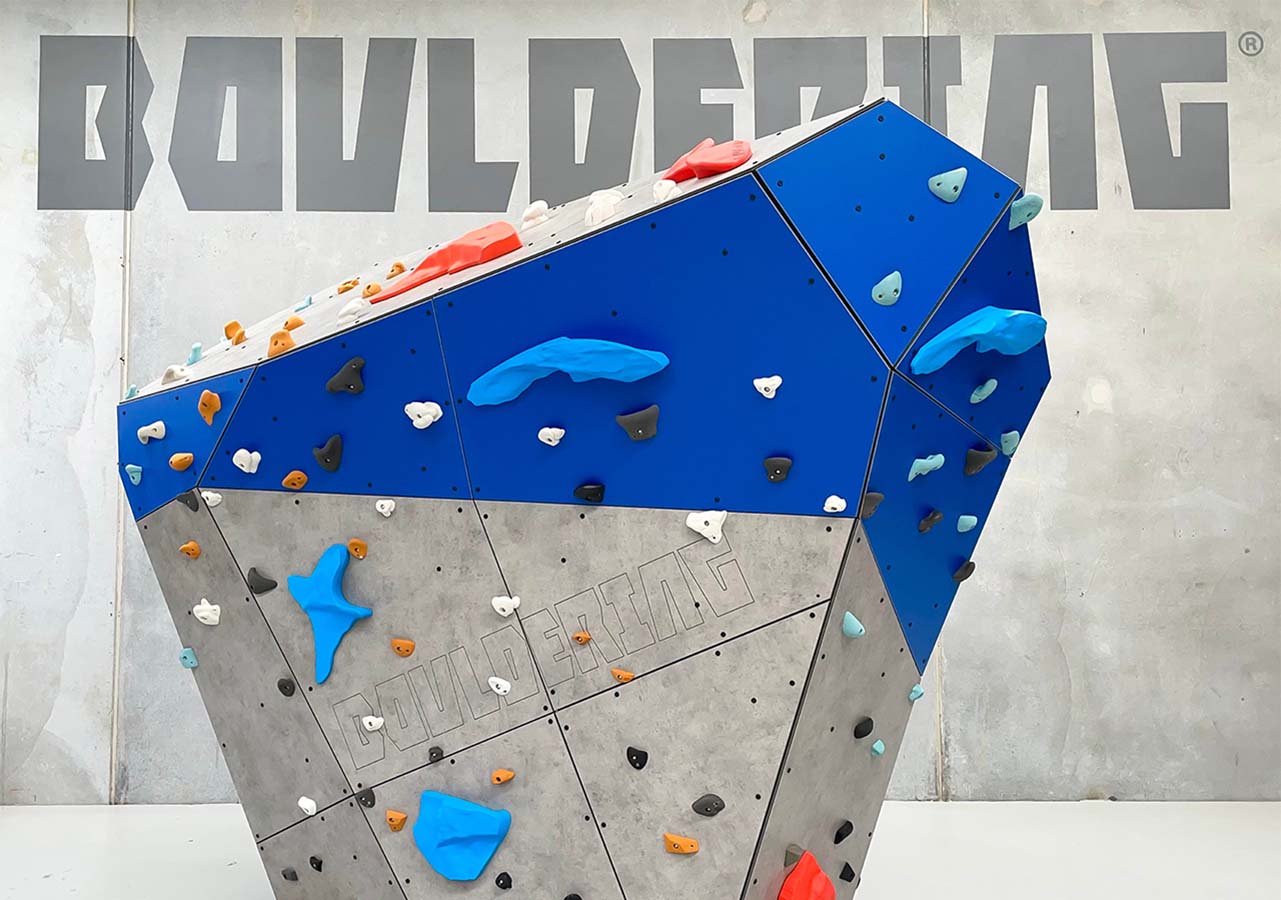

BOULDERING needed to be a solution with a visual connection to 'indoor bouldering' with a focus on the recognisable faceted climbing surface that is common in indoor climbing gyms. These climbing walls tend to have a very architectural aesthetic. We decided that using a similar style will help our market to relate to the product.

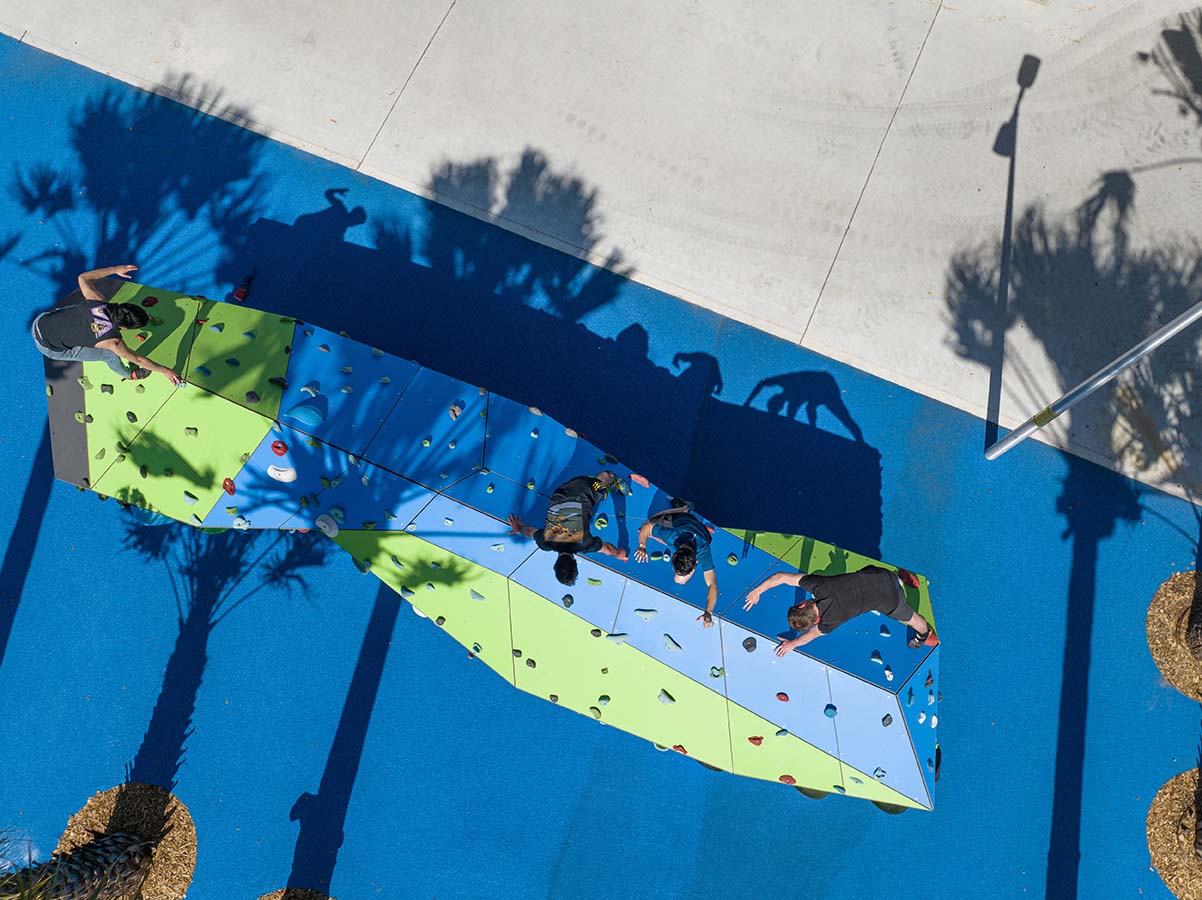

The solution also needed to be aesthetically pleasing, inviting, yet challenging. The large range of options using modular architecture allows BOULDERING to be adapted to any environment cost effectively. This is achieved through the design of the unique sub-frame and climbing panels. As the faceted panels have hundreds of individual joining angles, we engineered a detailed solution using custom steel joining members all uniquely manufactured to fit together with great accuracy. This allows complete freedom with our climbing surface design so we can provide a challenging series of faces to traverse.

Beyond the physical shape and engineering of our structures, we developed a range of climbing holds and volumes to enhance the user's experience and suit their capability. Each shape had to be used in a number of orientations, look like a 'family' of shapes yet be uniquely different and perform different functions. We developed methods for the shapes to be fixed to the climbing surface and also be tamper-proof. This is a critical element for ensuring public safety and product longevity. The design process also concentrated significant efforts to design-for-manufacture as we do all manufacturing in-house. Minimising waste, maximising efficiency in fabrication, building and finishing is a big part of the development focus.

We designed as a 'factory built, ship to site' concept to reduce time on site and maintain quality control and provide a feedback loop on future product development.