We began by identifying our design problem. This involved a design SPRINT, surveying nurses, and a few rounds of feedback. From here we broke the device into core components and brainstormed ideas using morphological analysis. Although fun, these initial concepts, which included vacuum sealed sponges and soft robotic arms were overly complicated. The idea to use pneumatics presented itself on a camping trip, when one of the team was inflating a dry bag.

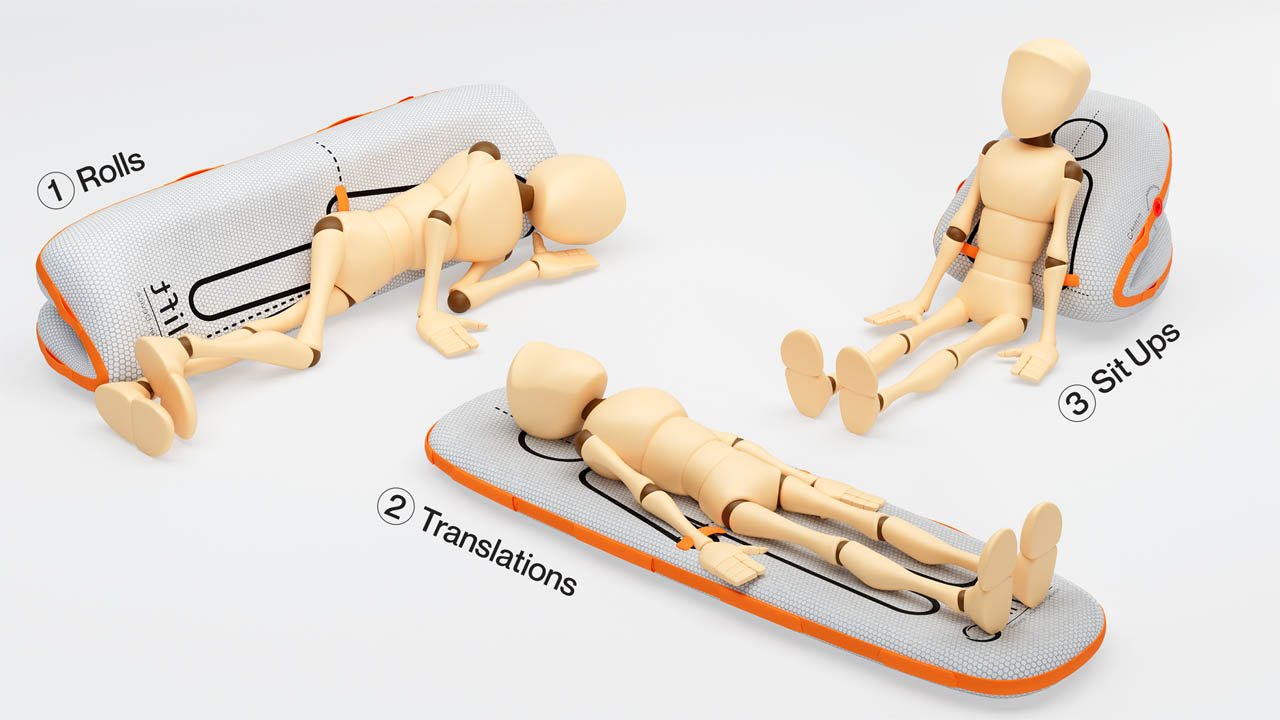

Realising the potential, we modified an inflatable lounge so that it could comfortably reposition a human, which served as our initial proof of concept. From there the design evolved into a kit consisting of a pump, an inflatable bladder, and a slide sheet. Soft body simulations were invaluable at this point, helping us to visualise how the device would work. Following interviews with experts in the field, we refined the concept further – and decided to combine the inflatable bladder and slide sheet into a single component. To assess how to safely handle patients, we modified a standard slide sheet, stitching handles around the perimeter. Finally, taking inspiration from market precedents, the pump was redesigned to better suit the needs of a mobile Healthcare Worker.