Landing lights are a very controlled item given the high level of safety that is required in the aeronautical market. The starting point is the International and local standards. MOS139 – Manual of Standards for Aerodromes, ICAO Aerodrome Design, FAA AC150/5345-46 or BS3224-4 covering lights. After reviewing the standards and the competitor’s products it was clear there was minimal innovation in the market, and that most products were just meeting the basic requirements.

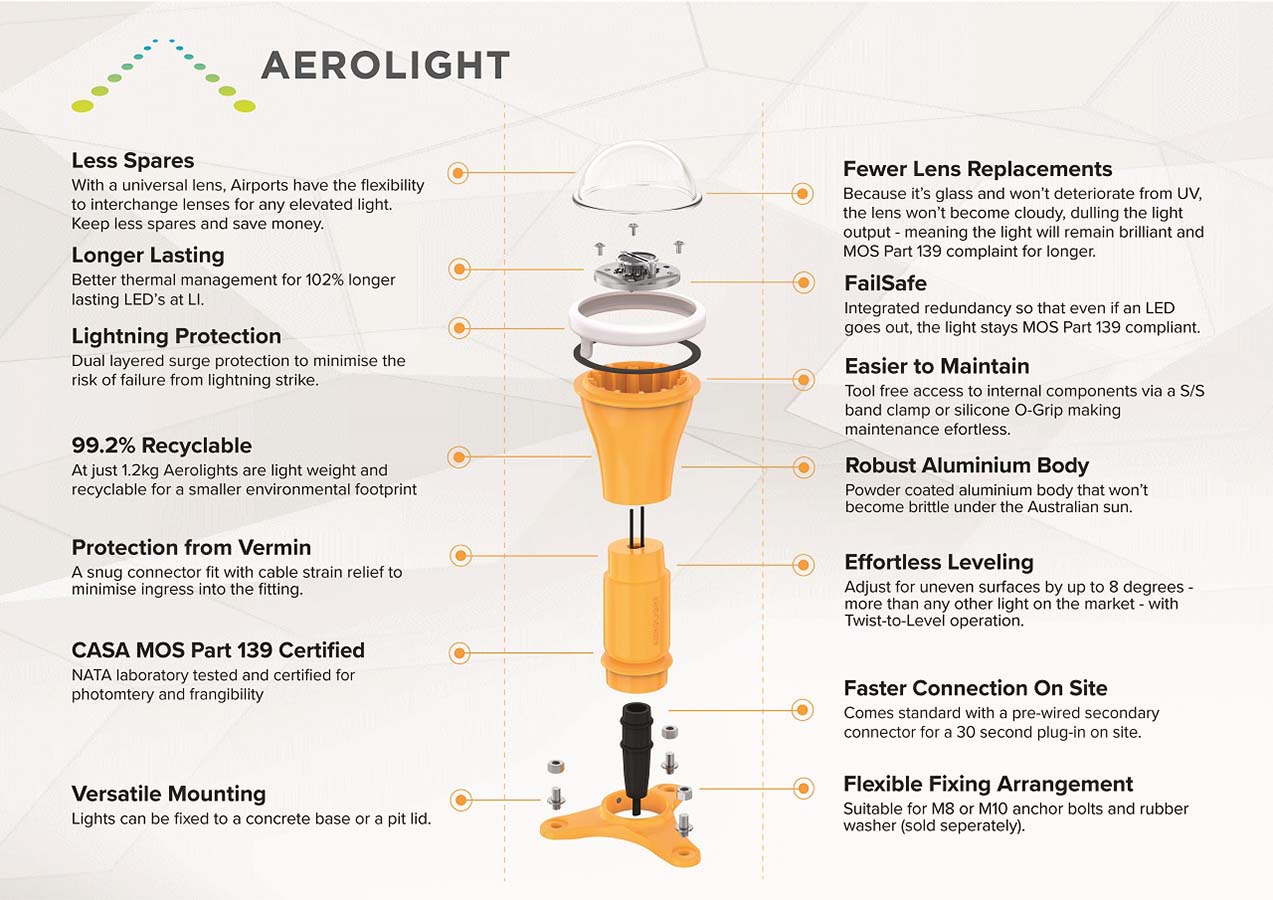

After identifying areas for improvement, we focused on the LED lighting and reflector design and the easy of installation and maintenance. Reliability and low running costs are important to airport operators. The optics required extensive photometric modelling using ray tracing. The housing design focused on the more traditional ideation, 3D modelling and Finite Element Analysis for frangibility, followed by performance test and certification. Extensive Design for Manufacturing was undertaken to make sure it could be produced cost-efficiently and to a high and enduring quality. The Aerolight exceeded the Design Brief on all critical dimensions.