To gain a more thorough understanding of the seaweed species and their properties I visited the seaweed farms and hatchery facilities run by the Seaweed Solutions CRC-P team down in Tasmania.

This opportunity helped me gain valuable insights into the farming process and the potential waste streams. Since the entire seaweed crop is photosynthetic, the plan was to utilize this B-grade harvest/residue to create a higher value architectural product.

Another resource identified was shellfish waste obtained by farming mussels alongside seaweed. This symbiotic relationship not only creates commercially viable biomass but also helps in ocean deacidification and habitat creation for other marine species.

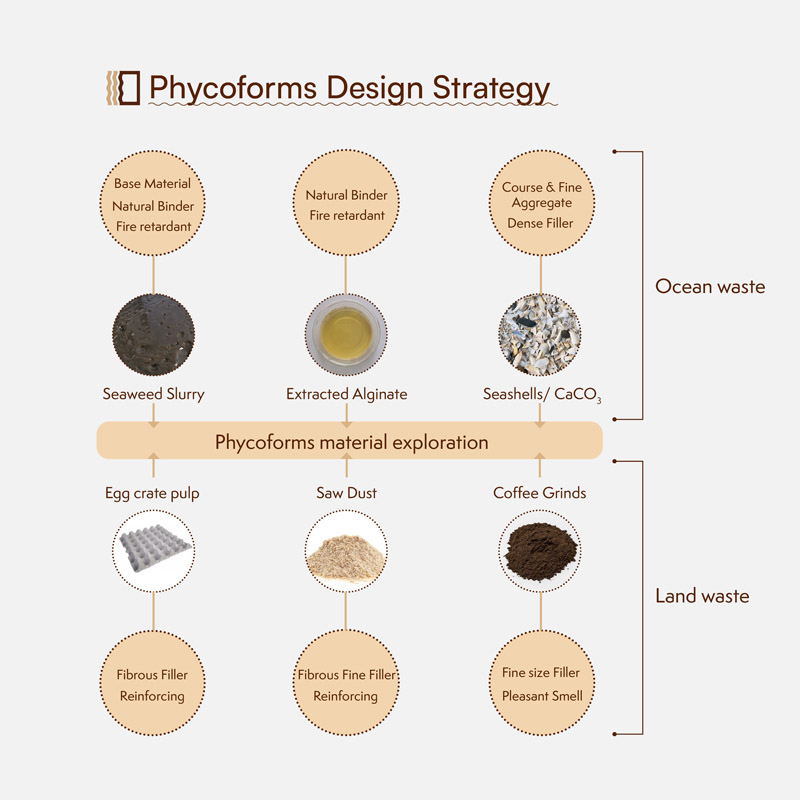

To carry out the preliminary material prototyping storm cast seaweed was collected from Mornington Peninsula and the other ingredients from local cafes and recycling facilities.

Extensive material research enabled the extraction of alginate in a home setting, and this led to further experimentation to understand the workability of the different ingredients. The lack of access to university facilities slowed down the material development but mentorship and guidance from experts in the seaweed industry enabled me to develop some promising prototypes.

Different species of brown seaweed were examined and in fact, the most promising prototype recipe with regards to strength and durability involved a combination of two harvested brown seaweed species.

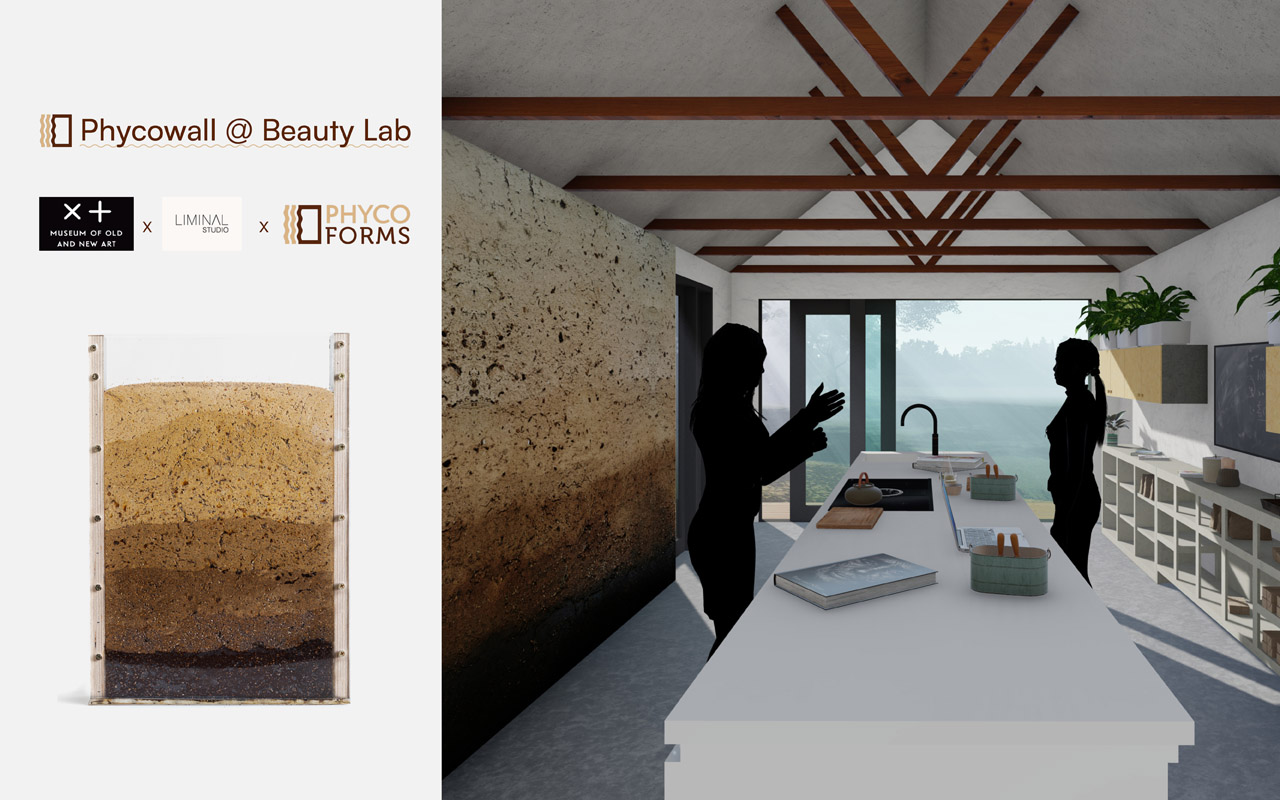

Drop tests at home proved that the strength was comparable to traditional bricks, but unfortunately, standardized lab tests to test compressive strength have not been carried out due to the recurring lockdowns.

Water susceptibility tests highlighted the need to explore biodegradable waterproof films. And fire resistance tests carried out at home using a blow torch showed that the presence of alginate and CaCO3 in the various samples aided in the structural adequacy and integrity of the prototypes.