The LUNA Modular AFO project started the design process with the research phase. The project began with an in-depth investigation into children’s common symptoms and conditions with Hereditary Spastic Paraplegia (HSP).

The information gathered established a base understanding of the physiological and biomechanical requirements of the design solution. Additionally, I also investigated existing AFOs and closely related solutions like physiotherapy braces through SWOT analysis and autopsies.

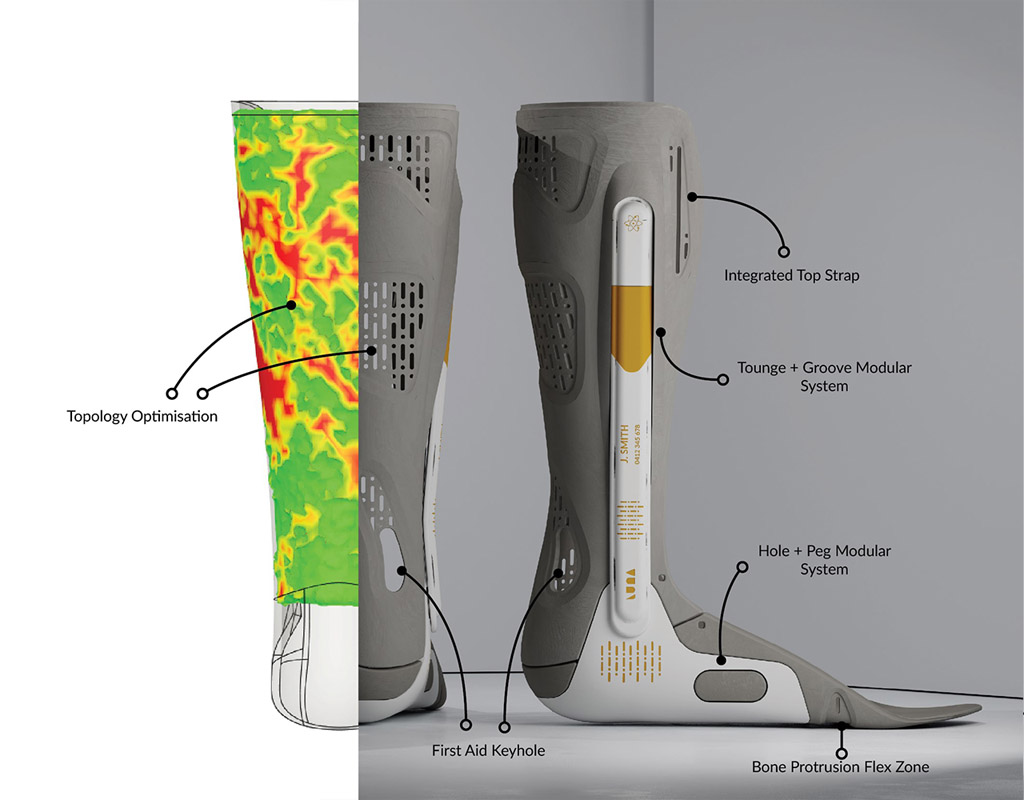

This revealed inconsistencies between the high-cost AFOs, which are much simpler in design and materials usage relative to the closely related solutions. Alluding to an opportunity for AFOs to use better technology, fabrication processes and clever design techniques like modularity and computerised generative design to create a superior solution.

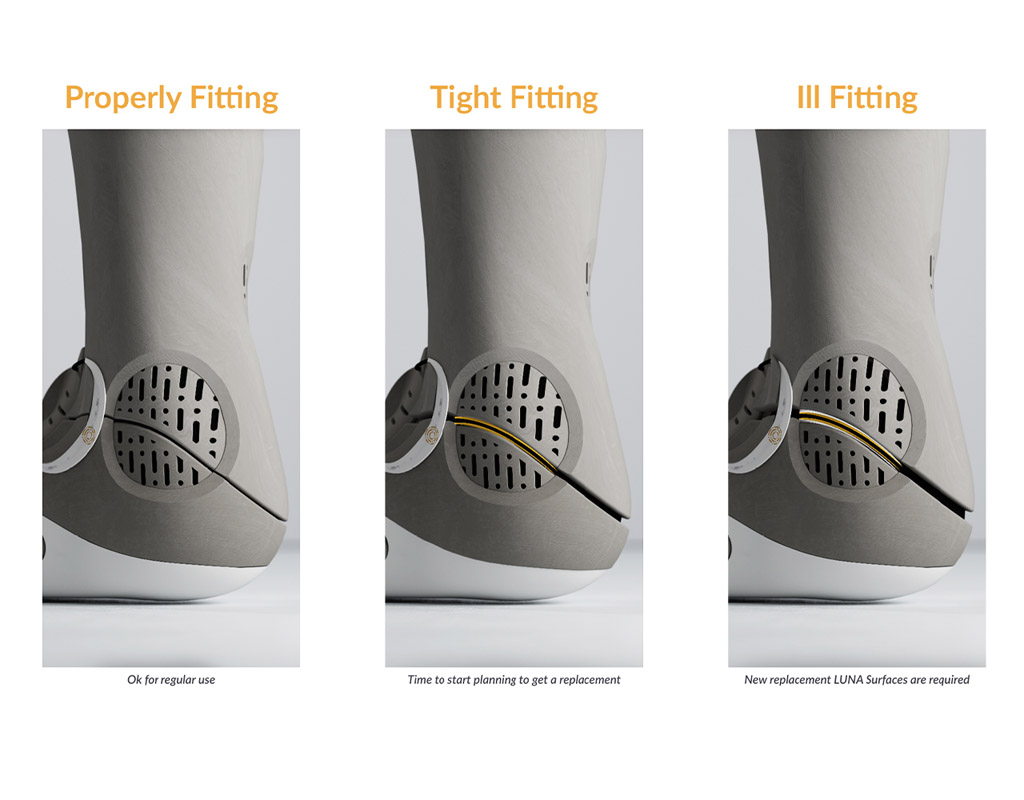

With this knowledge, the project developed an initial concept to use modular components to conform to growing children. The project then used this initial concept as a foundation to reach out and converse with industry professionals – Physiotherapists, Osteopaths, Child Orthotists and Biomechanical Engineers.

These interviews were crucial in confirming and correcting previous research. The industry contacts would continue to play a vital role in the design process, especially when integrating new fabrication processes into existing workflows.

The LUNA Modular AFO began physical development through an iterative process of ideation sketches, physical prototyping, CAD modelling and further prototyping with analysis steps supporting design decisions between each cycle.

These analysis steps consisted of user journey mapping, service mapping, subsequent interviews with industry professionals, material analysis and autopsies. Local and international fabricators were contacted to identify the ideal material and process and collaborated with the project to create a full-scale functioning prototype.

Ultimately, the iterative process allowed the project to consider all aspects of the design, from the orthotists to the end-user, providing a holistic design approach to the design solution.