The project began by identifying human input as the most viable way to generate heat energy without finite resources. Early prototypes focused on what this human input could look like; turning a generator to make heat through electricity, using a bicycle pump to create heat through friction - even harvesting heat from urine was considered. Ultimately it was friction that had the most potential, so efforts were directed at making a mechanism to effectively harness this heat generation technique.

These prototypes were made from an assortment of plumbing supplies, household objects, and retrofitted drink bottles. Their input motion progressed from pumping action to smooth rotation as ergonomics came into play.

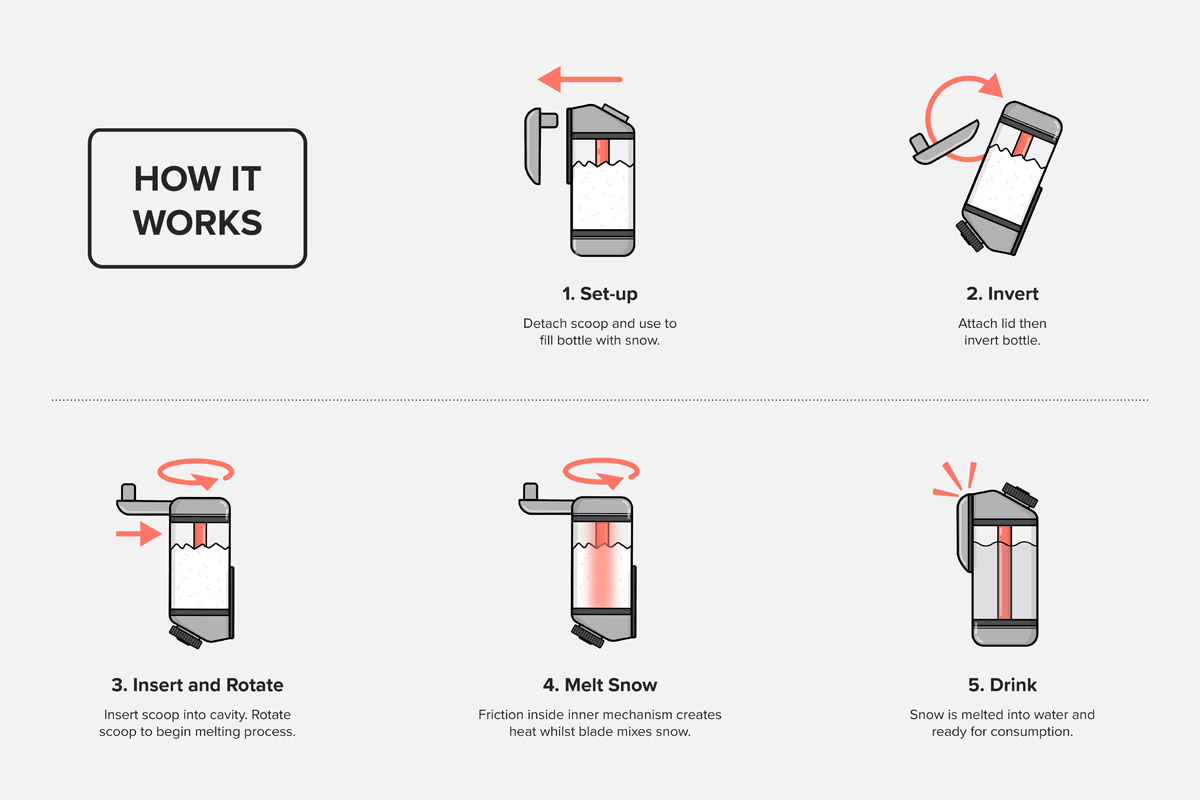

With rotating silicone fins in a copper tube showing promise for heat generation, testing identified a rotating blade was needed to pulverise snow as it was heated. 3D printing was used to create custom seals and linkages for this part. Issues with getting snow into this prototype identified the need for a detachable scoop.

To avoid adding extra components, the crank handle was redesigned to double as a scoop, detachable via magnets. After consultations with stakeholders and intensive workshop testing, prototypes were taken into the Victorian High Country (during winter) for final validation.

Through combining the insights gained in the design process, a high quality (largely 3D printed) final prototype was produced. This final prototype demonstrates design excellence as it fulfils the original design brief - to create a product capable of melting snow into water without a reliance on finite resources.