The design and development process for AddiVent was carried out during the 2020 Melbourne COVID-19 lockdown, with the team working from home in isolation for seven months. An extensive research phase was conducted to fully understand not only the landscape of existing low-cost ventilator designs, but the technical and medical requirements necessary for mechanical ventilation.

A Bag Valve Mask (BVM) squeezer design was chosen due to the maturity of research and development reached by other teams. From this research a technical criteria was defined, specifying the medical, technical, ergonomic and safety requirements for the device.

The team then worked through the detail design for AddiVent's various subsystems.

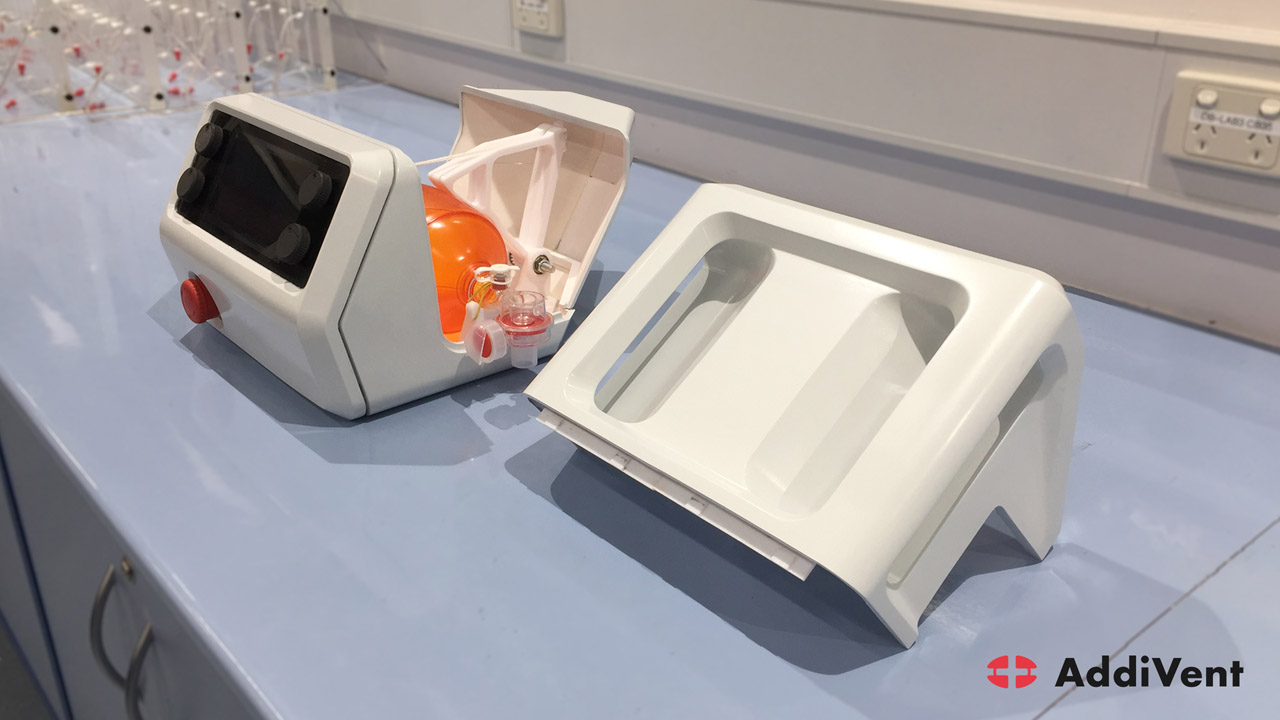

Development of the unique BVM squeezer mechanism took into consideration the specific requirements of the crowdsourced 3D-printed manufacturing approach.

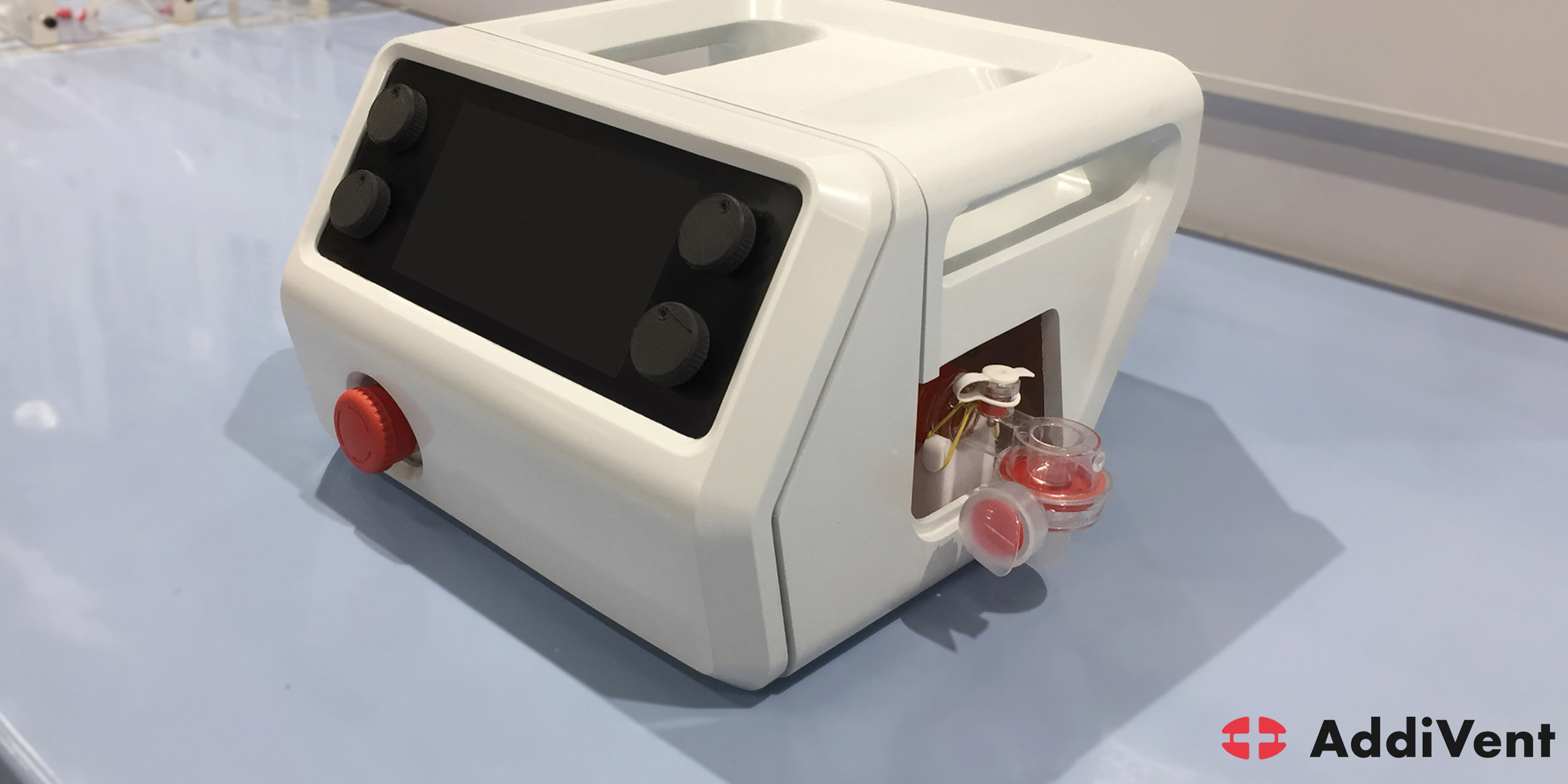

The packaging design development ensured the electrical and mechanical components were safely housed in a modern and resolved body, improving the product perception from an engineering prototype to a quality medical device.

The final design comprises 18 purchased electrical components, 40 3D-printed PETG parts, and 3 laser-cut acrylic panels.

The final unit costs around $500 AUD per unit, significantly less than standard mechanical ventilation devices. A complete prototype was manufactured and assembled to validate our body design. This was delivered alongside a detailed design report and two research papers detailing the entire research and development process.