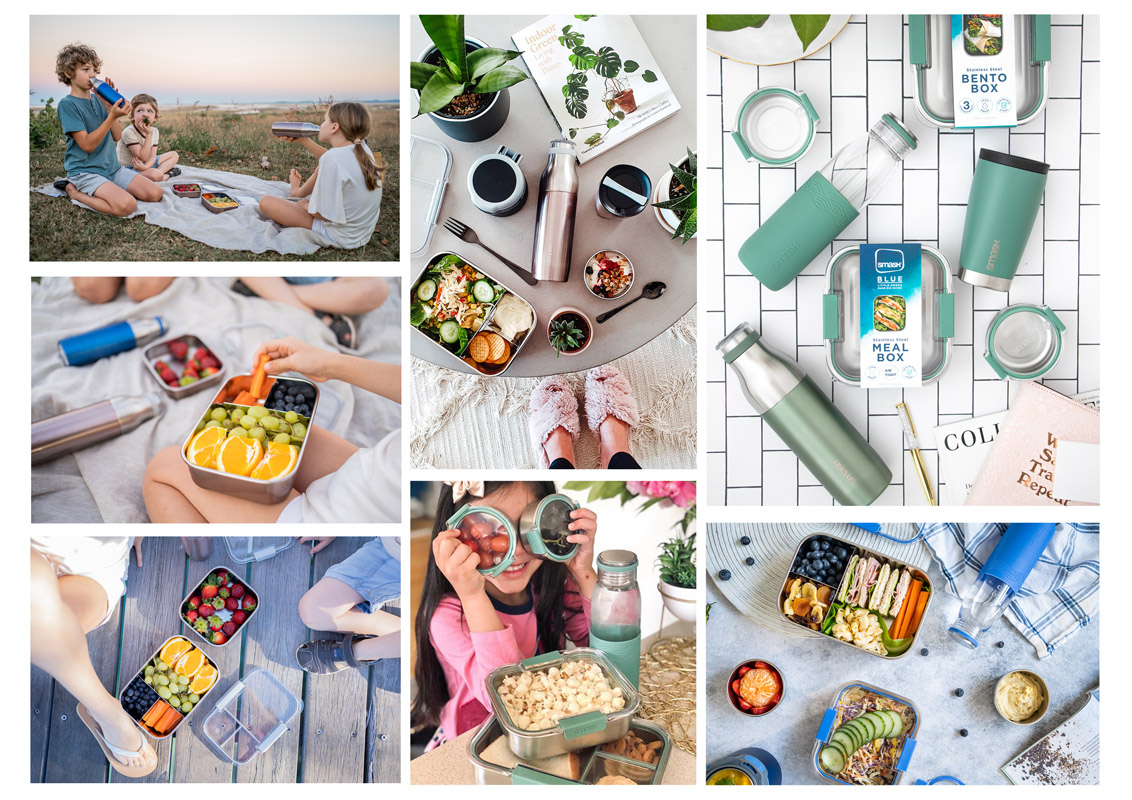

Once our internal ranging brief was completed and we had an understanding of the product requirements from sizing, features and usage to price points and SKU count.

The next step was to gain an understanding of stainless steel as a material, everything from its molecular structure to manufacturing techniques and capabilities so we could find a way to meet this brief. We spent two weeks in China meeting with countless suppliers, asking questions, looking and searching for inspiration and ideas.

We returned with a good understanding of what we could achieve and a plan to mix materials and parts from multiple manufacturers. Our sizing and functionality was put to the test with multiple concepts and prototypes until we landed on solution that achieved our goals and had consumer confidence when presented in focus groups.

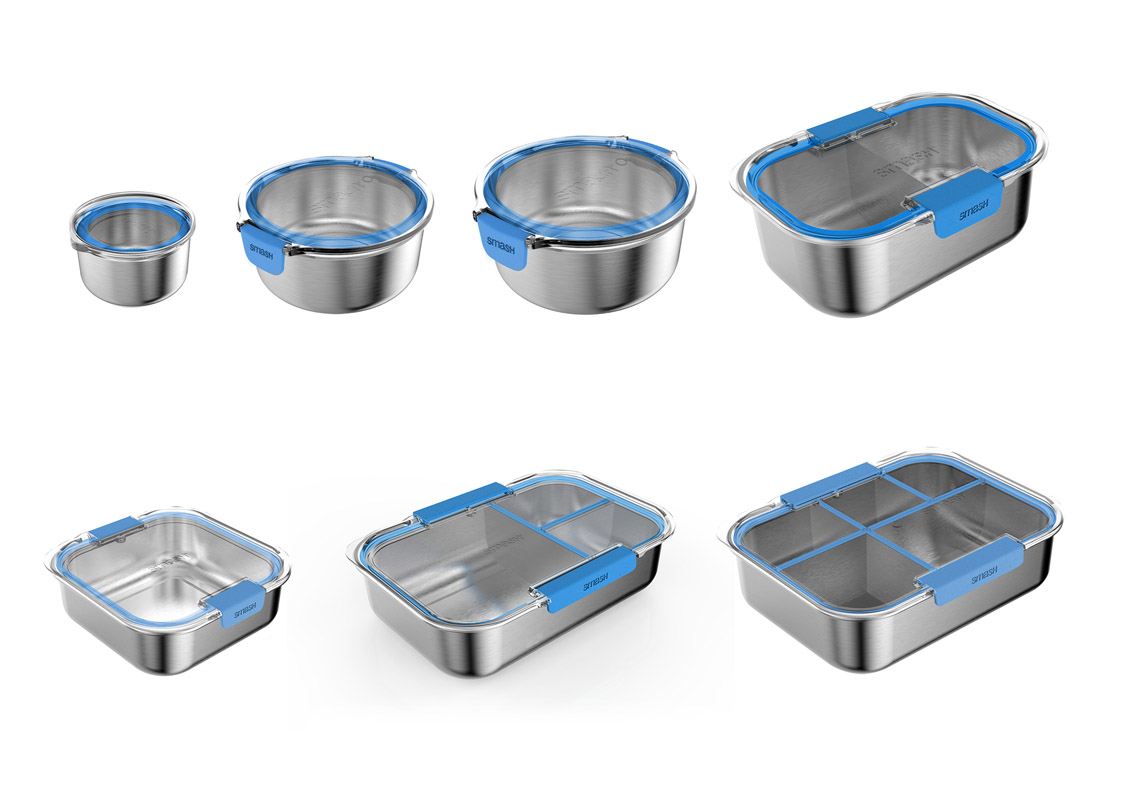

The biggest challenges for the project was transferring the functionality of traditional plastics to an eco-friendly material like stainless steel that is significantly more difficult and costly to manufacture. The consumer’s need to reheat food challenged us to engineer a food grade stainless steel that is microwave and oven safe.

To ensure no leaks and spills, we designed each container with a silicone perimeter and a hidden release valve to create a leak proof seal that accommodates the manufacturing inconsistencies of the stainless steel base. We elected to use a BPA FREE, 100% recyclable glass-like Tritan material for the lid.

Research showed that being able to see inside the vessel and the aesthetics it provided expanded the products reach to non eco warriors, assisting some consumers to adopt a new format and begin their eco journey. Little Drops make Big Waves after all.