To begin, heavy research of existing ROV products was conducted to find a suitable solution for the Australian market. This information proved that international inspection class ROV’s are highly expensive with long turn around times from purchase to final delivery.

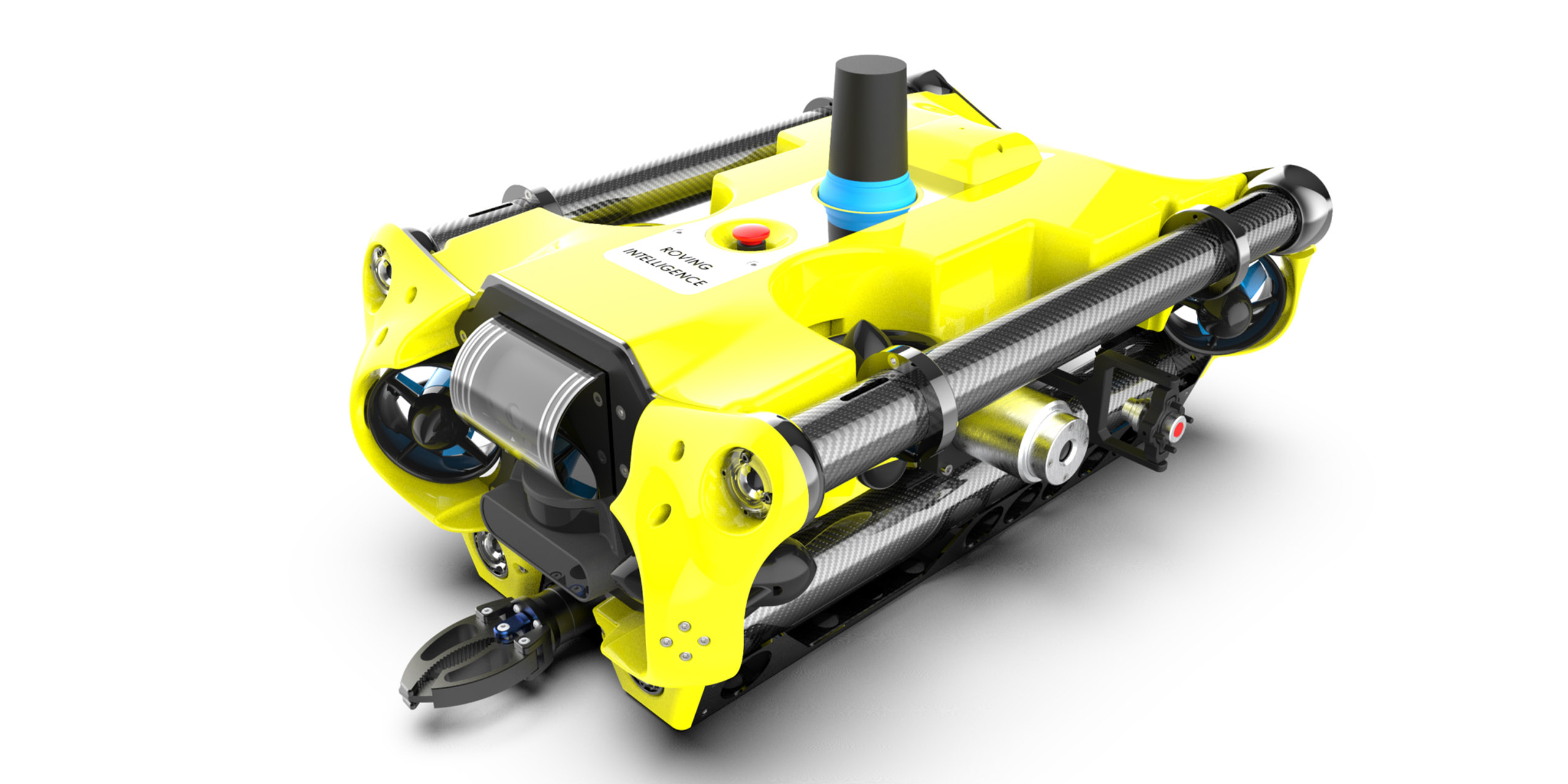

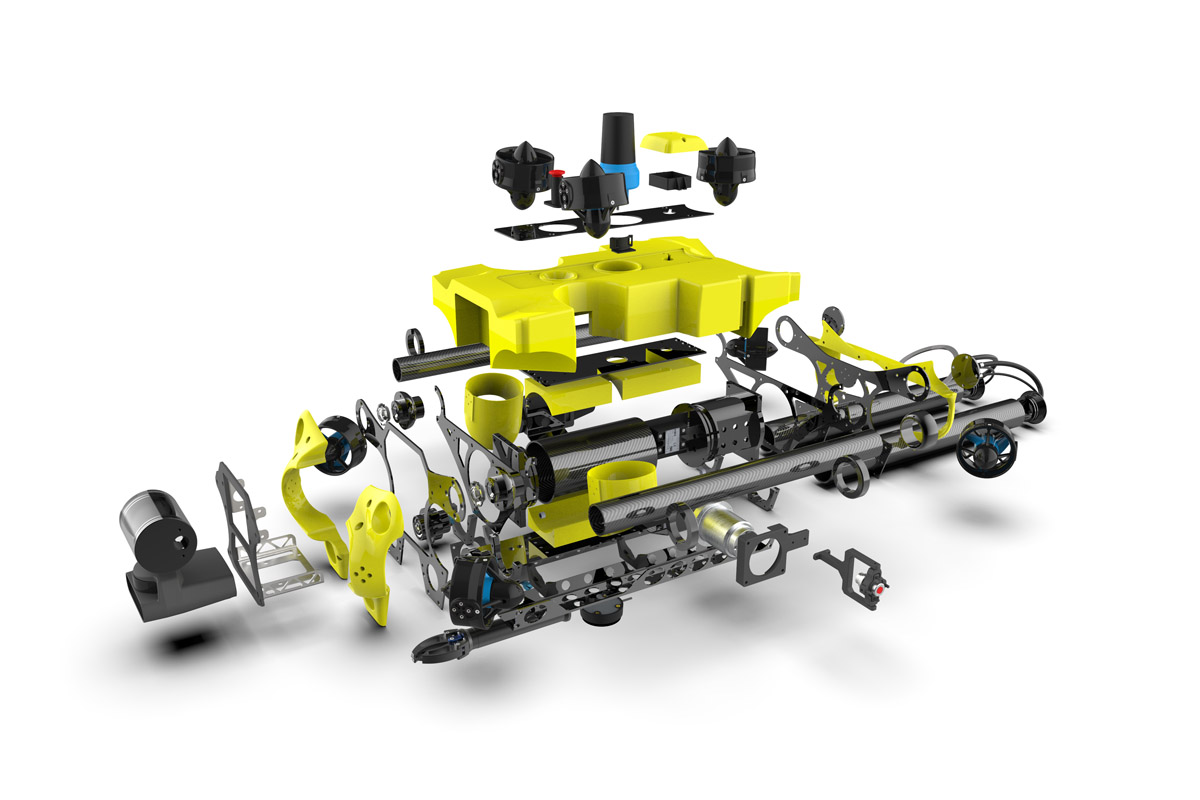

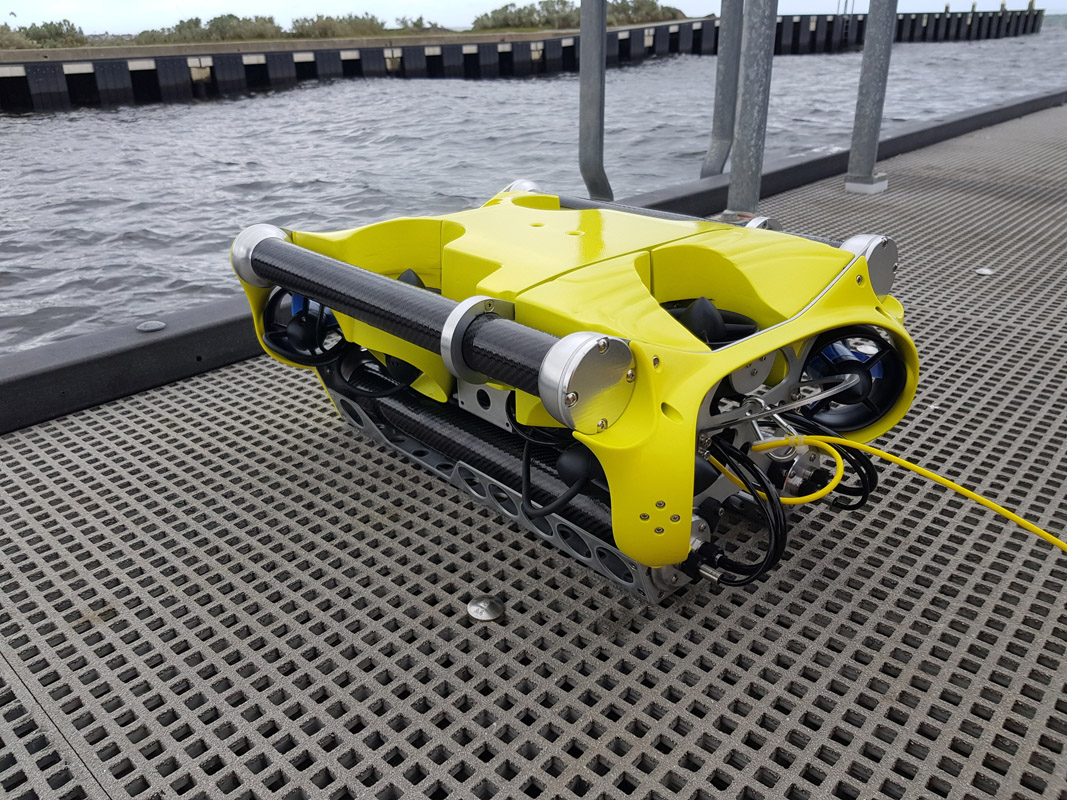

With this in mind, we set out to design our ROV with cost effective manufacturing techniques, while also incorporating the use of rapid prototyping and durable, recyclable materials. Robustness was another aspect of the design heavily concentrated on, as our research and experience show these vehicles are subject to tough conditions and environments.

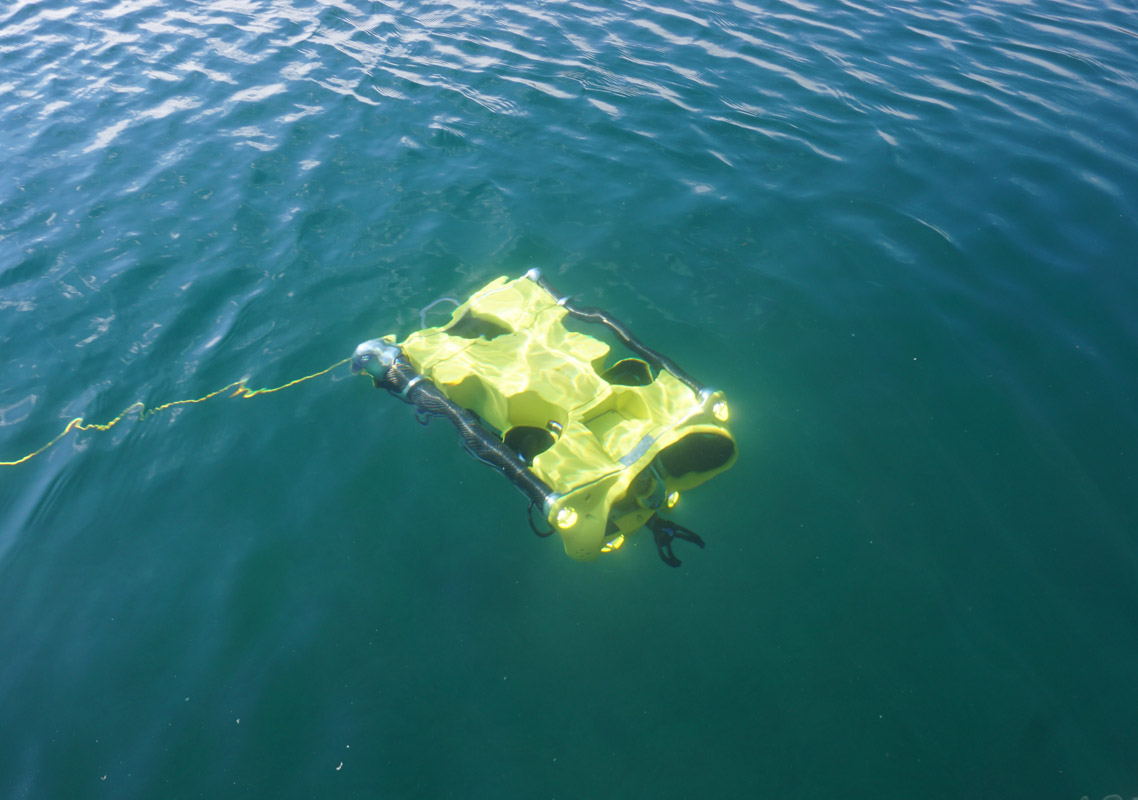

There are many obstacles that can easily stop an average ROV in its tracks, potential damage sustained could result in expensive repairs or deem it completely unrecoverable.

We canvased 7 industry experts across 4 key industry pillars (Major Ports, Councils, Aquaculture and Oil & Gas) to ensure the specification of our design meet or surpassed user / industry requirements.

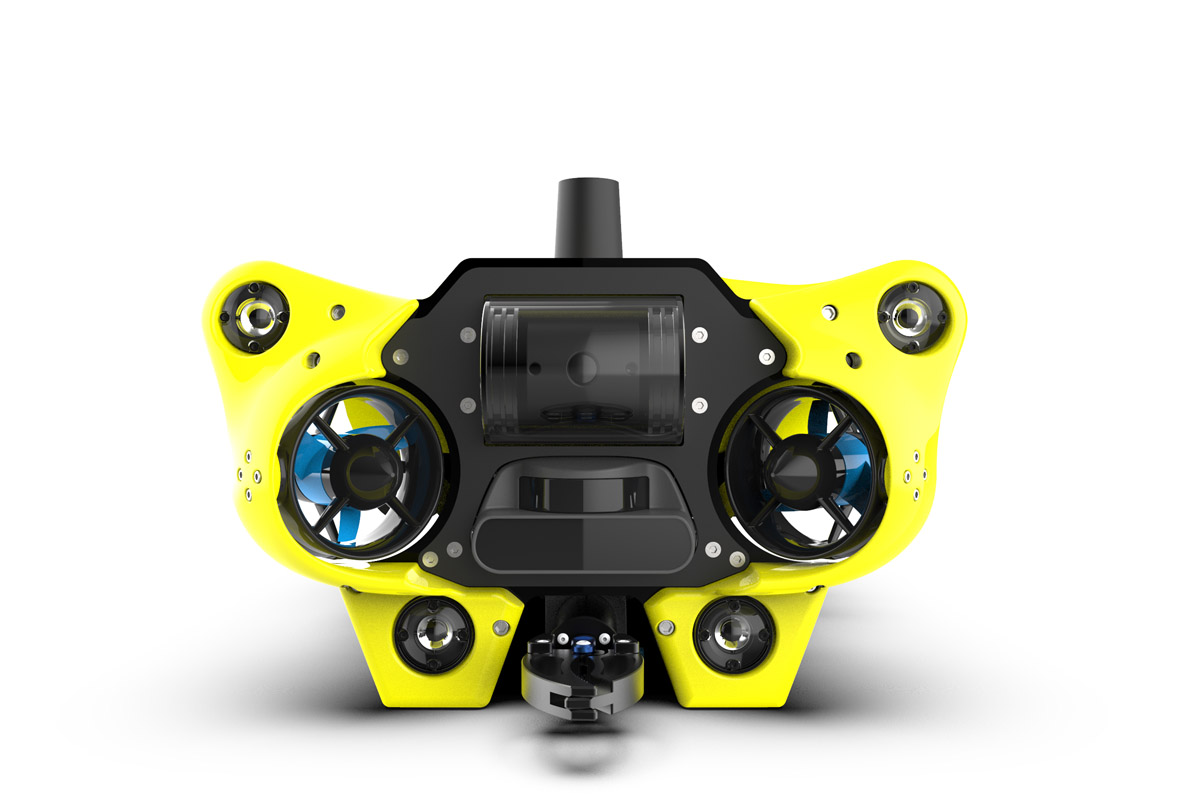

Fluid dynamics was another consideration in this design process. With durability being another main focus, we set out to have flowing rounded fairings on the front and rear to minimise the drag when propelling through the water.

The multipurpose fairings also add design flair aesthetically to our ROV giving it character and an instant recognisable face. These fairing are also an important structural component to house and protect four horizontal thrusters and prevent the front camera lens from making contact with any obstacles.

Other design considerations are the standard and addition payload placements, each one is integrated so they can easily be removed and replaced on site, while also being located for optimum performance and functionality.