The Brutalis Collection was made possible via a Creative Victoria ‘2021 Sustaining Creative Workers Grant’ which led to collaborations with local creative workers and manufacturers during the product development process.

Prior to the process commencing, advice was sought from RMIT Associate Professor of Materials, Science and Engineering and the Tyre Stewardship Australia Organisation to determine whether the hypothesis was feasible.

Upon satisfying concerns about binders, fire resistance etc. the process of working out the best way to bind and mould the granulated recycled car tyre rubber began. Acustico Lighting collaborated with Envirorubber Solutions Pty Ltd who currently create commercial ramps and speed humps using granulated rubber with a binder.

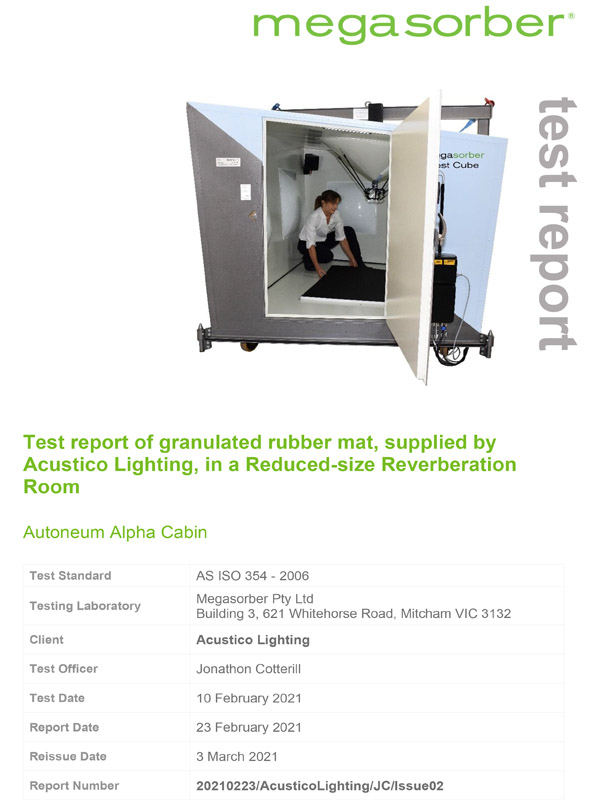

It took a couple of iterations to perfect a sample that could then be scientifically tested for its acoustic properties in an Autoneum Alpha Cabin.

Once satisfied that the acoustic properties were of high enough standard to create a commercially viable product a number of further iterations were initiated.

Added to the rubber/binder combination were concrete chips to create the look of terrazzo concrete. A number of moulds were designed, the rubber proved a difficult and uncompromising partner. The design was changed a number of times to suit the malleability and reduce the cost per unit.

Concealed recycled aluminium forms the internal base for the LED strip lighting to be housed and included is an added up-light feature to bathe the ceiling in soft light. The LED is available in a range of different wattages and lumen counts. Minimal suspension wires suspend it from the ceiling and a cloth-covered flex with minimal ceiling plate provide high-end finishing details to the light. It comes with a European remote driver.

Most components (apart from the lighting hardware) are manufactured in Melbourne and assembled at Studio Acustico, the headquarters of Acustico Lighting.