STAGE 1 - CONCEPT & PROTOTYPING

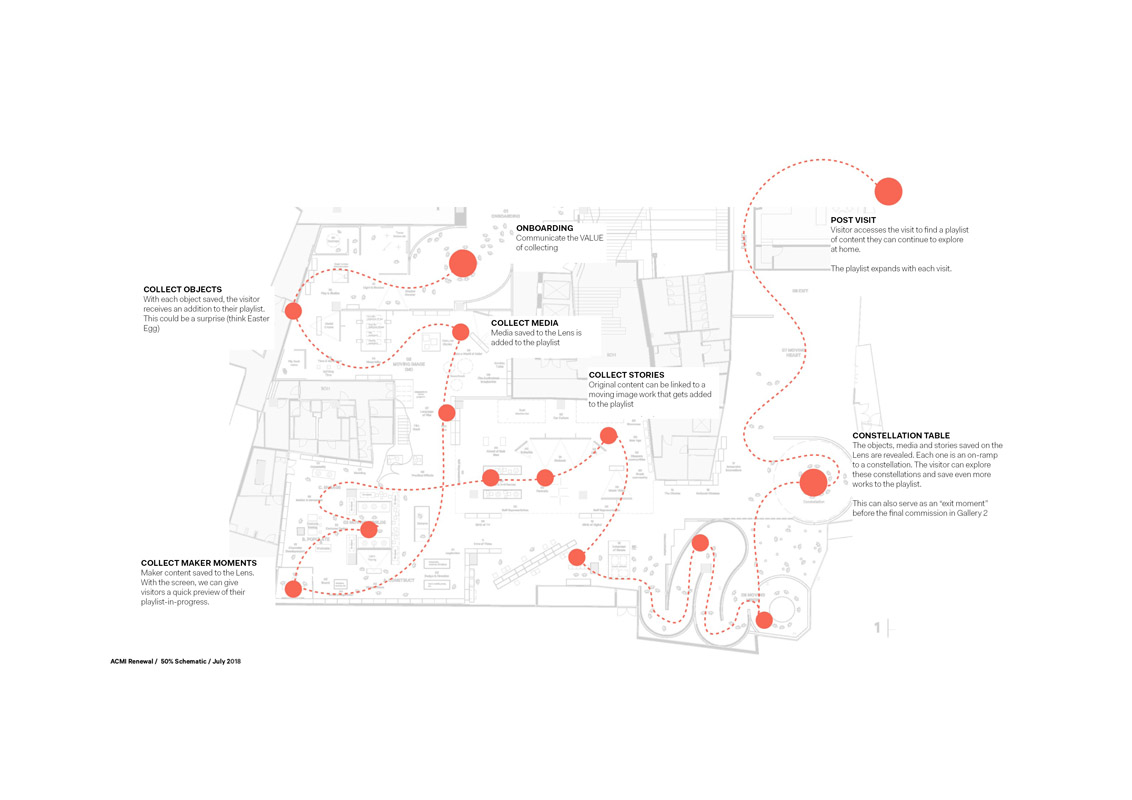

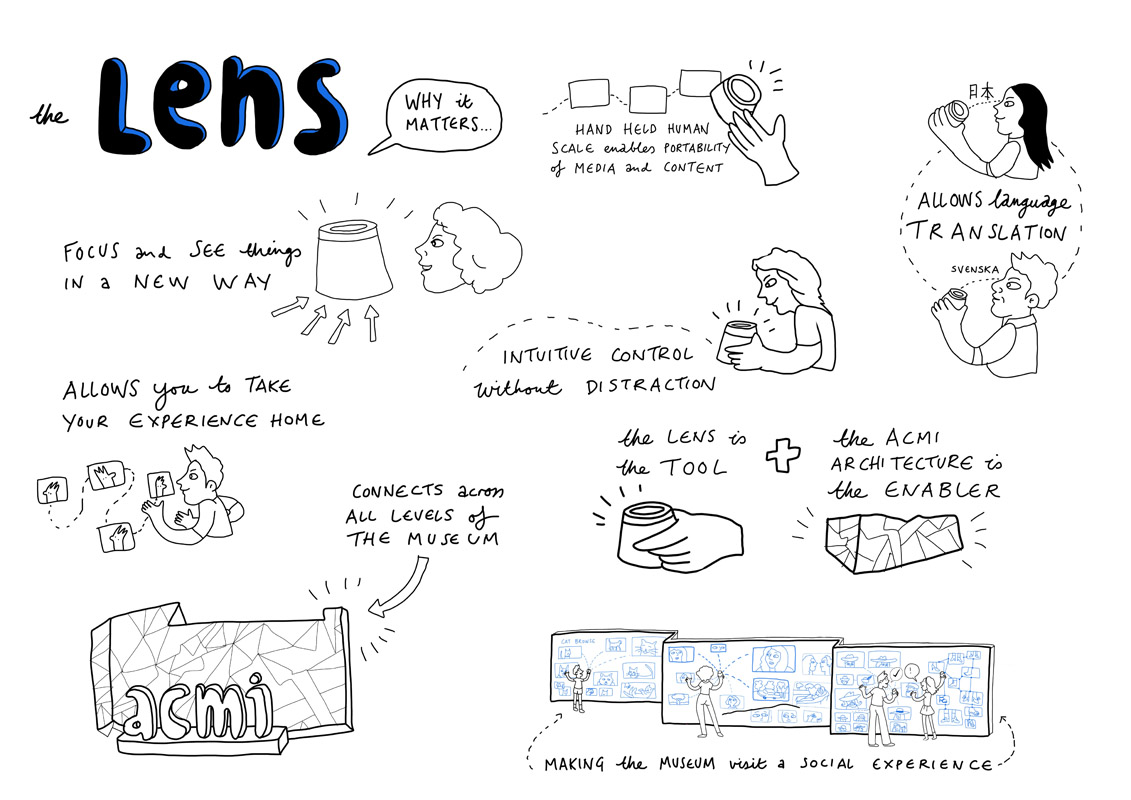

ACMI worked with Publicist Sapient over 18 months to develop functional prototypes that were tested at multiple stages with museum goers - from paper prototypes to initial plastic models.

STAGE 2 - DEFINE

CDI reassessed the original brief - ensuring that the original constructs and requests were still relevant. An in-depth research document was written - with a focus on available recyclable, compostable, and biodegradable methods and materials - and which would suit this project.

Probably the biggest discovery during this stage was the difficulty in printing on an eco-friendly translucent material, and the hurdles surrounding the correct disposal of the NFC chip. Several concepts, quote estimates and one-off prototypes were put forward for consideration, before a direction was chosen.

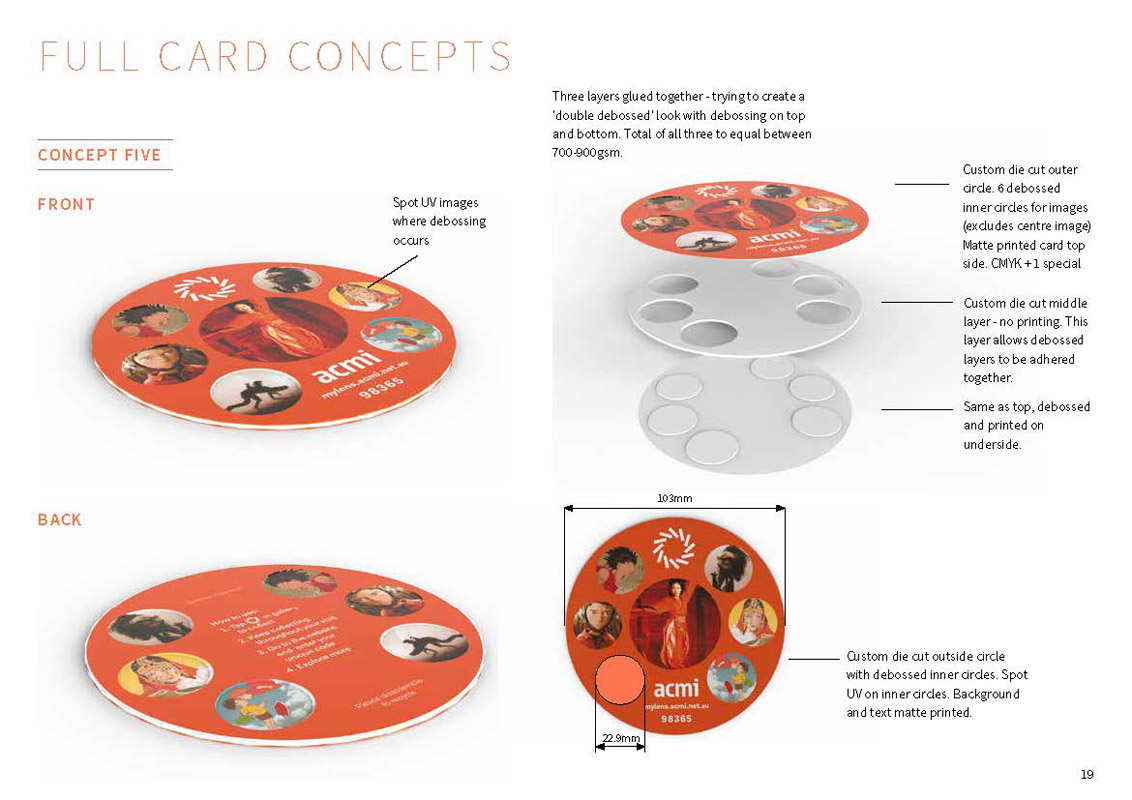

STAGE 3 – DESIGN

The concept direction chosen was a 'full card' design, that played with textures and surface finishes to re-create the look and feel of the original lens. The NFC was to be a sticker, that was located on a tear-away section that could be removed before recycling. To minimise production error, the unique code was also printed on the sticker - so that each NFC could accurately be matched to the right code. This helped to reduce waste caused by coding and NFC malfunction.

STAGE 4 - REFINE

The Refine stage kicked off with the CDI team sourcing and meeting with potential manufacturers, and establishing any possible hurdles that may be met in regards to the unique design and layout. Several final prototypes were made in-house and by the selected manufacturer, with several refinement phases. A complete set of detailed manufacturing drawings were also developed.

STAGE 5 - DELIVER

The final stage saw CDI and ACMI manage the production of the first 250k units, with several sample revisions required to perfect the final products. 750k further units are en route to ACMI.