The aims and objectives of this research were to: (1) materialise the concept of a mycelium based biocomposite artificial wetland composed of interlocking modules (2) Test the prototype in a real-world environment and collect data.

To achieve the objective, the following were produced, tested, and analysed in a lab environment to inform the final outcome:

Material composition and fabrication:

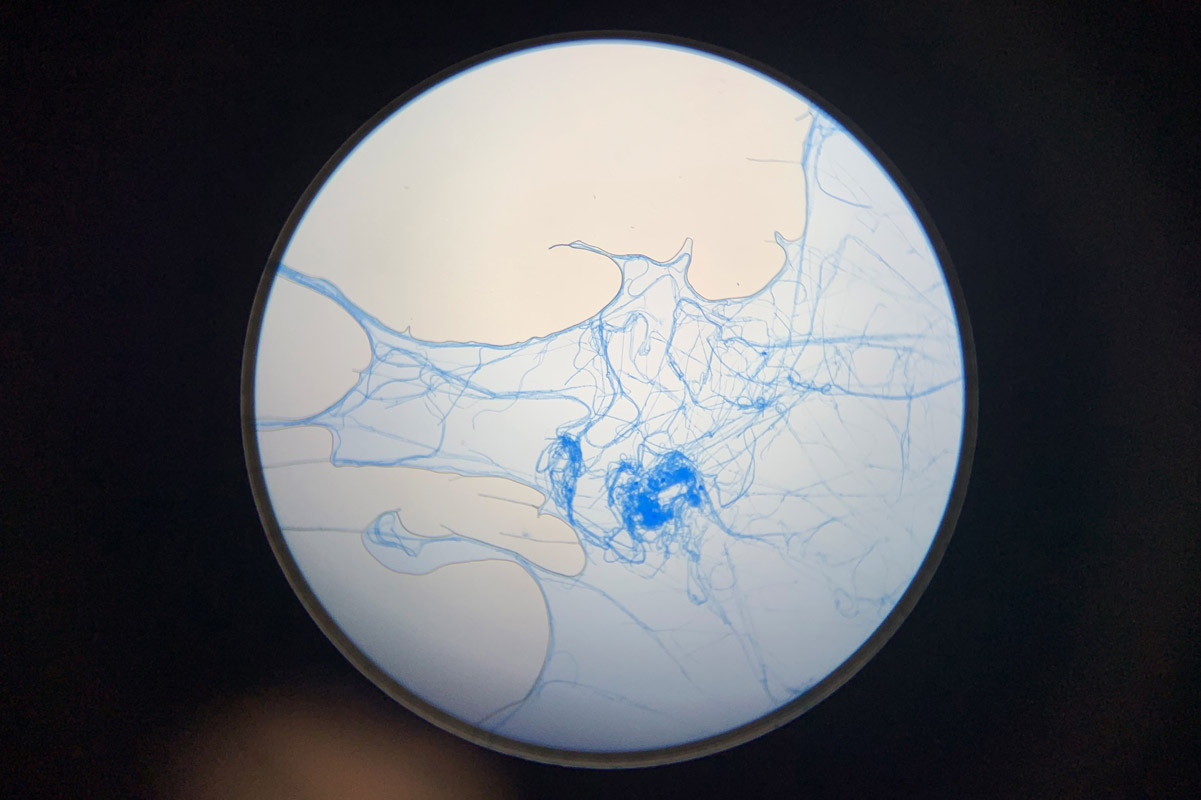

Different fungi species were tested as their network structure varies in strength, density, and growth rate between the various types. Different organic waste substrates were tested. While mycelium can colonise most cellulose-based organic waste, the geometries and granularity of the substrate impact the strength of the mycelium material (e.g. fibrous materials apply better than particles).

Growing conditions: The incubating environment impacts the outcome of a bio-fabrication process. Optimal temperature, moisture levels were tested, as the ability to maintain an averaged moisture distribution and access to air across the material within a module is important for scalability.

Buoyancy: The desired submergence level of the wetland was calculated using mycelium-material density, soil density, plant weight, the mass of internal timber support, potential water absorption and impact on mycelium structure.

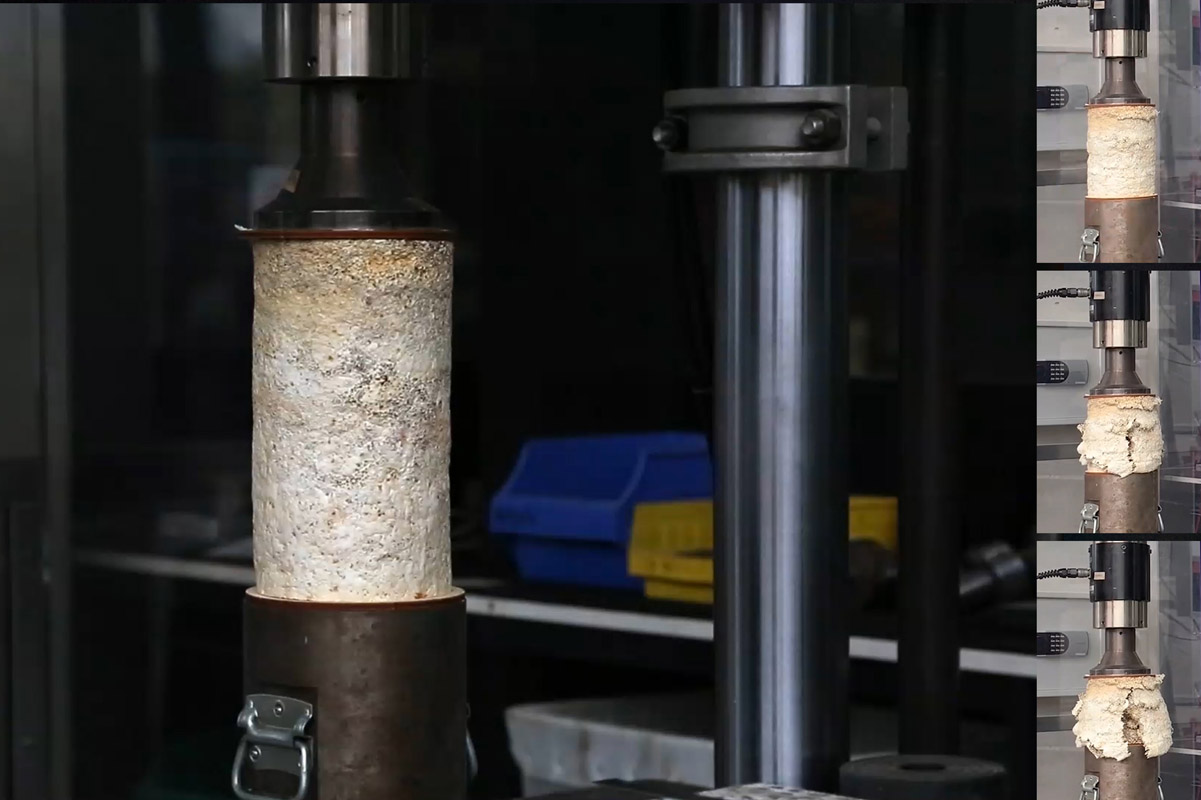

Structural capacity: Various prototypes were created and tested in Swinburne’s structural lab.

The design outcome was 3x800mm diameter triangular-shaped modules. The modules are made with a bio-composite material composed of mycelium and sawdust. While mycelium can colonise and digest a range of cellulose materials, sawdust was used as the substrate for its linear and fibrous forms, which when bound by mycelium results in greater material strength. The mycelium material is set within specially designed moulds that expand to form the structure of the floating wetland. Above the surface, native wetland plants were grown within the compound to create a habitat for insects and birds while the roots penetrate the base for water purification.